Method for improving performance uniformity of finished product through heat preservation and slow cooling after rolling

A technology of heat preservation, slow cooling and uniformity, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of heating steel plates with a large amount of gas, high maintenance costs, high energy consumption costs, etc., to achieve energy saving, low input costs, and excellent results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

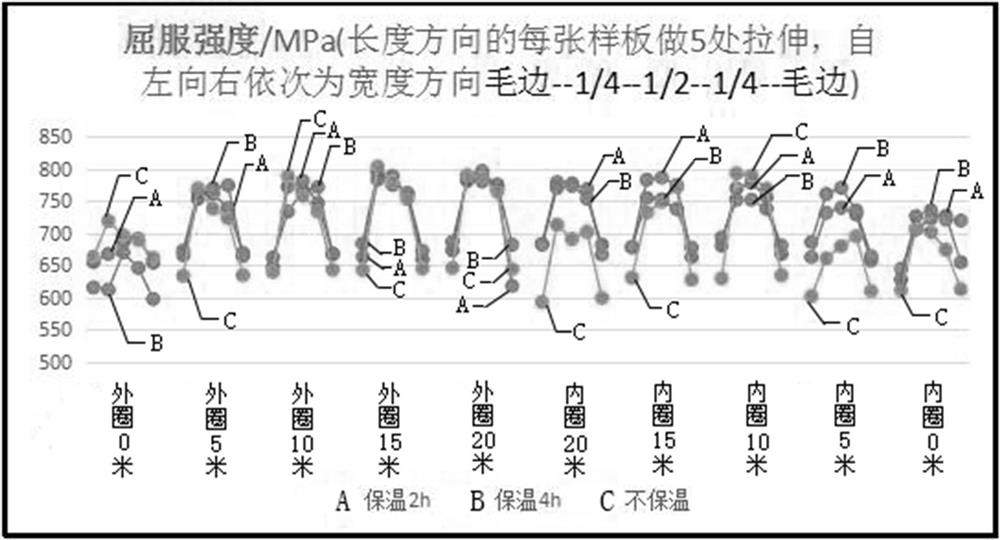

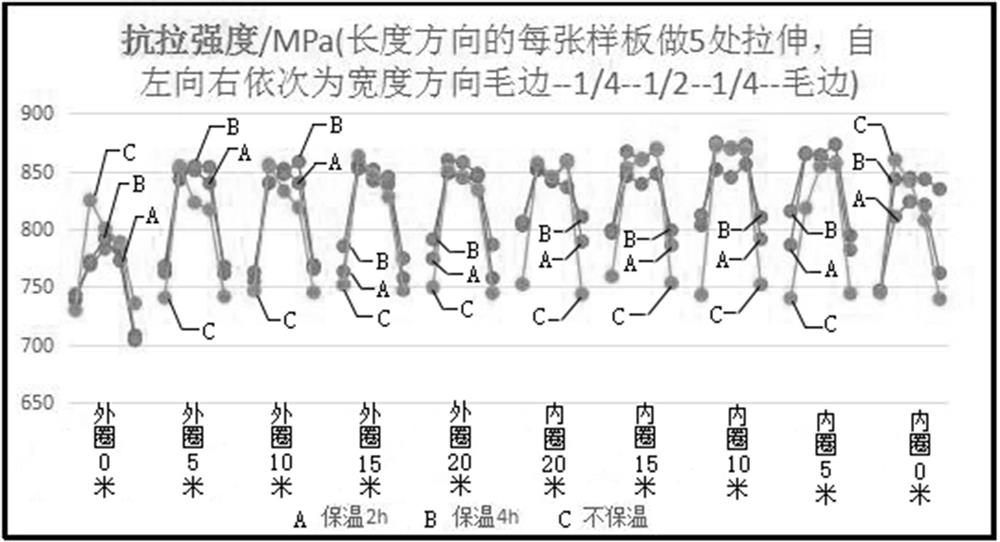

[0015] The technical solutions in the embodiments of the present invention will be described below in conjunction with the accompanying drawings.

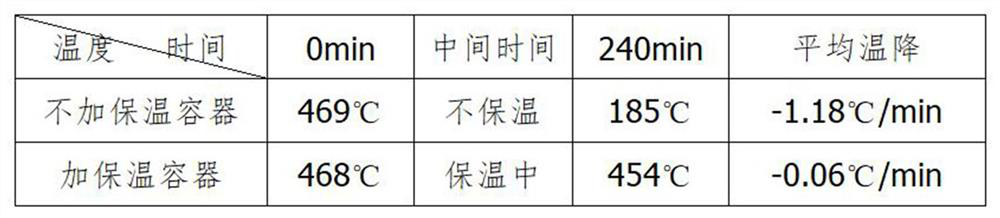

[0016] A method for heat preservation and slow cooling after rolling to improve the uniformity of finished product performance, which is used in a hot-rolled coil insulation cover device. Cover base, gas protection device, internal ventilation device, semicircular heat preservation cover, electric heating device, thermocouple, described method comprises the following steps:

[0017] Step 1: Use the crane to lift the semi-circular heat preservation cover and separate it from the base of the heat preservation cover of the transport chain tray. After the steel coil is produced, the base of the heat preservation cover of the transport chain tray moves to the steel coil output port through the transport chain tray and the transport chain. Load the finished steel coils on the base of the heat preservation cover of the transport chain pal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com