Technology for recovering production of electrolytic zinc powder and lead powder from smelting ash through alkali leaching method

A technology of electrolytic zinc and soot, applied in the field of smelting, can solve the problems of inability to achieve purification effect, difficult to adapt to purification methods, pungent odor of ammonia, etc., and achieve the effect of high recovery rate, low equipment requirements and high market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention can be further described by the following examples, however, the scope of the present invention is not limited to the following examples.

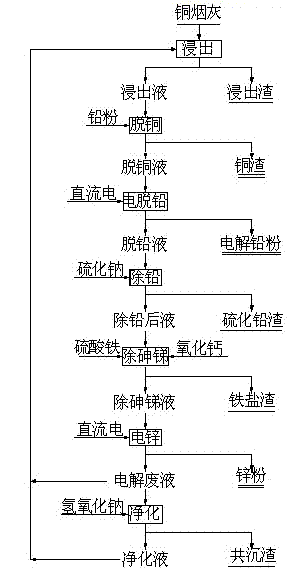

[0034] Operate according to the process shown in Figure 1.

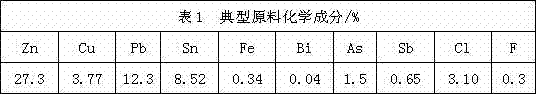

[0035] A typical chemical composition of smelting soot is shown in Table 1.

[0036]

[0037]

[0038] ① Leaching

[0039] According to the liquid-solid mass ratio of sodium hydroxide solution leaching agent to smelting soot of 10:1, the free alkali in the leaching agent is 200 g / L, at a temperature of 80 °C, react for 5 h, and the free alkali at the end of the leaching reaction is 160 g / L. Liquid-solid separation to obtain clarified leaching solution (containing zinc, lead, copper and impurities such as iron, arsenic, antimony, etc.) and tin-containing leaching residue;

[0040] ② Lead powder decopper

[0041] Add electrolytic lead powder with 5 times the mass of copper in the leaching solution to the clarified leaching solution described in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com