Low-luster PC/PBT (polycarbonate/polybutylene terephthalate) alloy material and preparation method thereof

An alloy material and low-gloss technology, which is applied in the field of low-gloss PC/PBT alloy materials and its preparation, can solve the problems of excessive surface gloss and achieve the effects of good fluidity, easy availability of materials, and excellent matte effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

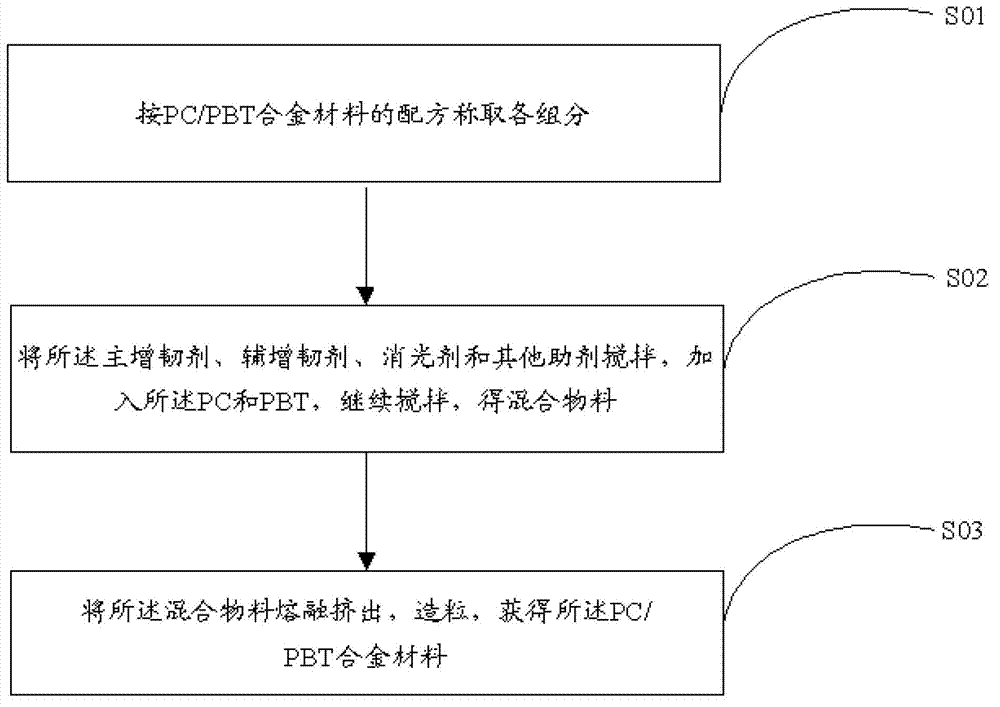

[0040] see figure 1 , showing a method for preparing a low-gloss PC / PBT alloy material according to an embodiment of the present invention, which includes the following steps:

[0041] S01: Weigh each component according to the formula of the above-mentioned low-gloss PC / PBT alloy material;

[0042] S02: Stir the primary toughening agent, secondary toughening agent, matting agent and other additives, add the PC and PBT, and continue stirring to obtain a mixed material;

[0043]S03: Melt-extrude the mixed material and granulate to obtain the low-gloss PC / PBT alloy material.

[0044] Specifically, in step S01, all materials are weighed accurately, accurate to 0.001 kilogram. The preferred content and type of each component in the low-gloss PC / PBT alloy material formula are as above, and will not be repeated here to save space.

[0045] Step S02 specifically includes adding the main toughening agent, auxiliary toughening agent, matting agent and other additives into the high-s...

Embodiment 1

[0050] Components and weight percentages thereof of the low-gloss PC / PBT alloy material of the present embodiment are:

[0051] PC 65%;

[0052] PBT 17%;

[0053] Main toughening agent 5%;

[0054] Auxiliary toughening agent 2%;

[0055] Matting agent 3%;

[0056] Inorganic filler 3%;

[0057] Compatibilizer 3%;

[0058] Antioxidant 2%.

[0059] Wherein, the main toughening agent is ethylene-butyl methacrylate-glycidyl acrylate copolymer; the auxiliary toughening agent is methyl methacrylate-butadiene-styrene with core-shell structure Structural impact modifier; the inorganic filler is 500-1500 mesh calcium carbonate or talcum powder; the compatibilizer is PCTG; the matting agent is cross-linked styrene-styrene nitrile polymer; The antioxidants are tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and tris(2,4-di-tert-butylphenol) phosphite 1:1 mixture by weight. The PC is polycarbonate with a refractive index of 1.58-1.61 and a transmit...

Embodiment 2

[0062] Components and weight percentages thereof of the low-gloss PC / PBT alloy material of the present embodiment are:

[0063] PC 70%;

[0064] PBT 12%;

[0065] Main toughening agent 6%;

[0066] Auxiliary toughening agent 1%;

[0067] Matting agent 4%;

[0068] Inorganic filler 4%;

[0069] Compatibilizer 2%;

[0070] Antioxidant 1%.

[0071] Wherein, the main toughening agent is ethylene-butyl methacrylate-glycidyl acrylate copolymer; the auxiliary toughening agent is methyl methacrylate-butadiene-styrene with core-shell structure Structural impact modifier; the inorganic filler is 500-1500 mesh calcium carbonate or talcum powder; the compatibilizer is PCTG; the matting agent is cross-linked styrene-styrene nitrile polymer; The antioxidants are tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and tris(2,4-di-tert-butylphenol) phosphite 1:1 mixture by weight. The PC is polycarbonate with a refractive index of 1.58-1.61 and a transmit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com