Modified natural graphite particle and method for producing same

A natural graphite and manufacturing method technology, applied in the direction of graphite, active material electrodes, electrical components, etc., can solve the problems of large irreversible capacity and low filling density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

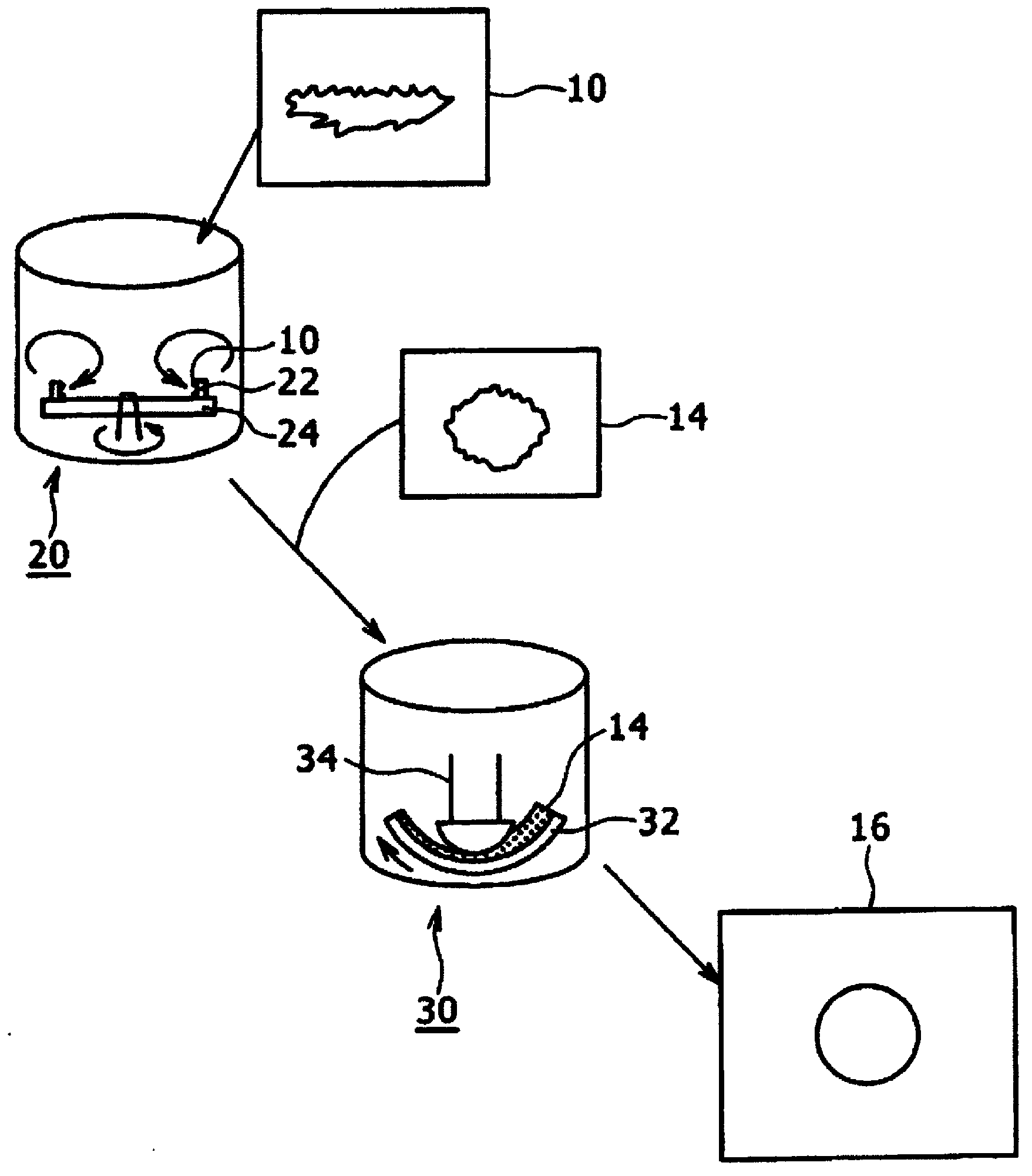

Method used

Image

Examples

Embodiment 1

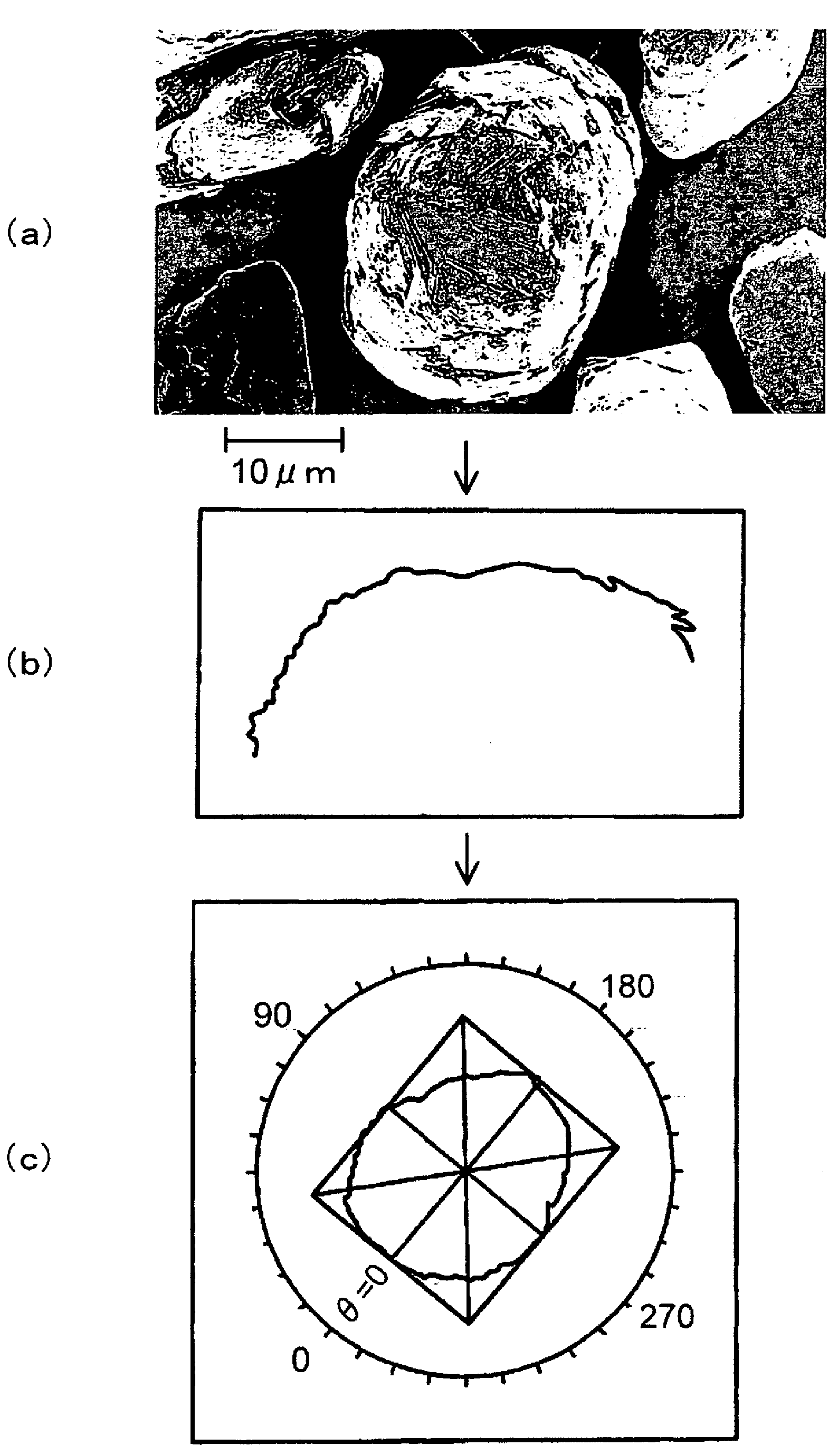

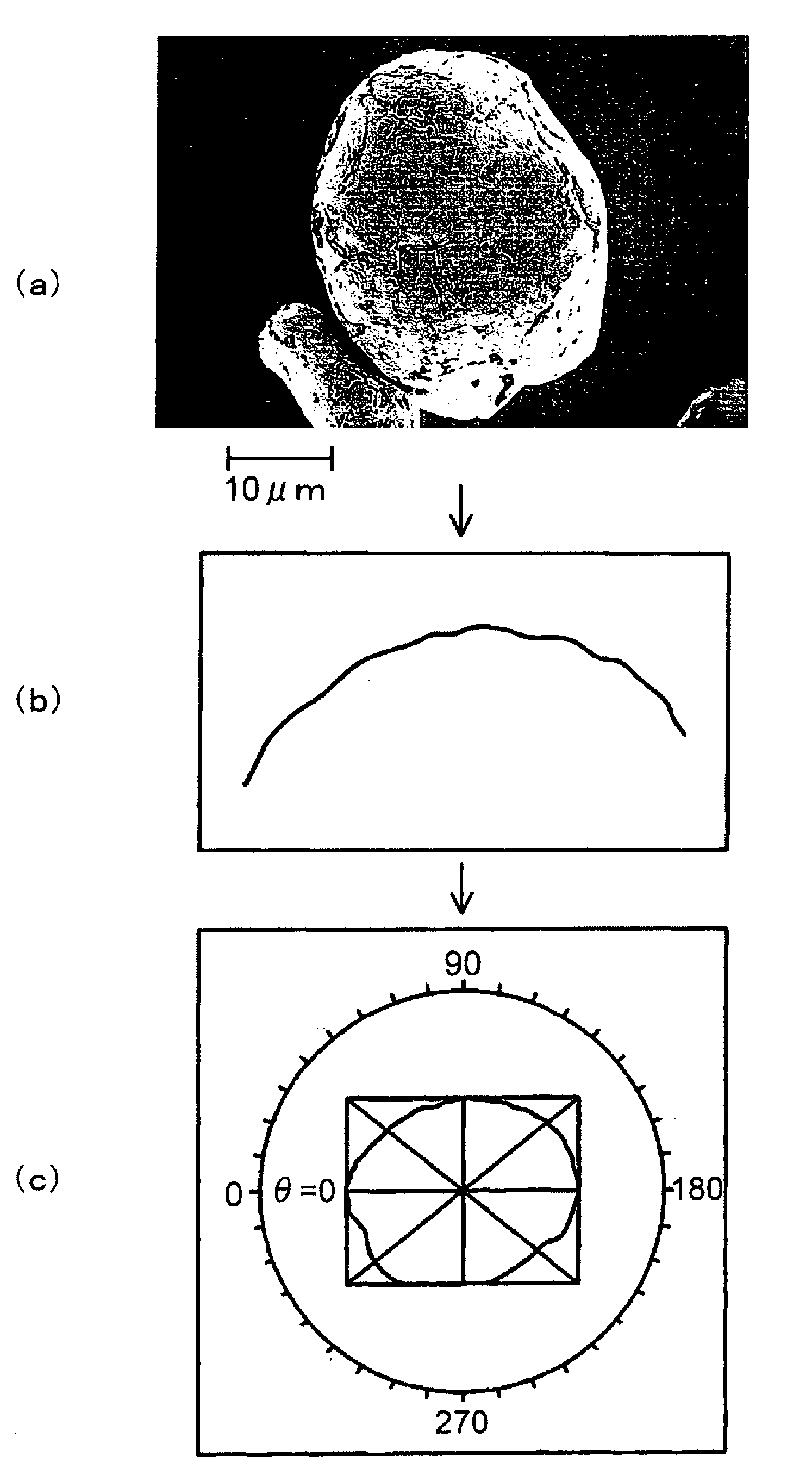

[0099] (Example 1) Example 1 is the modified natural graphite particles 16 described above.

Embodiment 2

[0104] (Examples 2 to 5) Examples 2 to 5 are particles obtained by using the same manufacturing steps as the above-mentioned modified natural graphite particles 16, and are for explaining the case of using particles with different average particle diameters (the preparation method is as above.) example of. Example 2 is the particles processed by the mechanical milling device 30 for Comparative Example 4. Similarly, Example 3 corresponds to Comparative Example 5, Example 4 corresponds to Comparative Example 6, and Example 5 corresponds to Comparative Example 7.

[0105] Regarding circularity, average particle diameter and specific surface area, comparing Examples 2 to 5 with the corresponding Comparative Examples 4 to 7, no major difference was found.

[0106] Regarding the tap density, when Examples 2 to 5 were compared with Comparative Examples 4 to 7 corresponding thereto, it was found that any of the tap densities in Examples 1 to 5 were improved. The tap density is prefer...

Embodiment 6

[0112] (Example 6) 20% by mass of coal tar pitch powder having an average particle diameter of 20 μm was mixed with the modified natural graphite particles of Example 4, and heat-treated at 1000° C. for 1 hour in a nitrogen gas flow. The pitch powder is melted during the heat treatment to wet the surface of the modified natural graphite particles, and then becomes a carbonaceous material formed of low-crystalline carbon by carbonization. In this way, a carbonaceous material adhered to the surface of the modified natural graphite particles was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com