Inorganic foam heat insulating material and preparation method thereof

A thermal insulation material and inorganic foam technology, applied in the field of thermal insulation materials, can solve the problems of low mechanical strength, lower thermal insulation performance, high water absorption rate, etc., and achieve the effects of good thermal insulation performance, long service life and low water absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

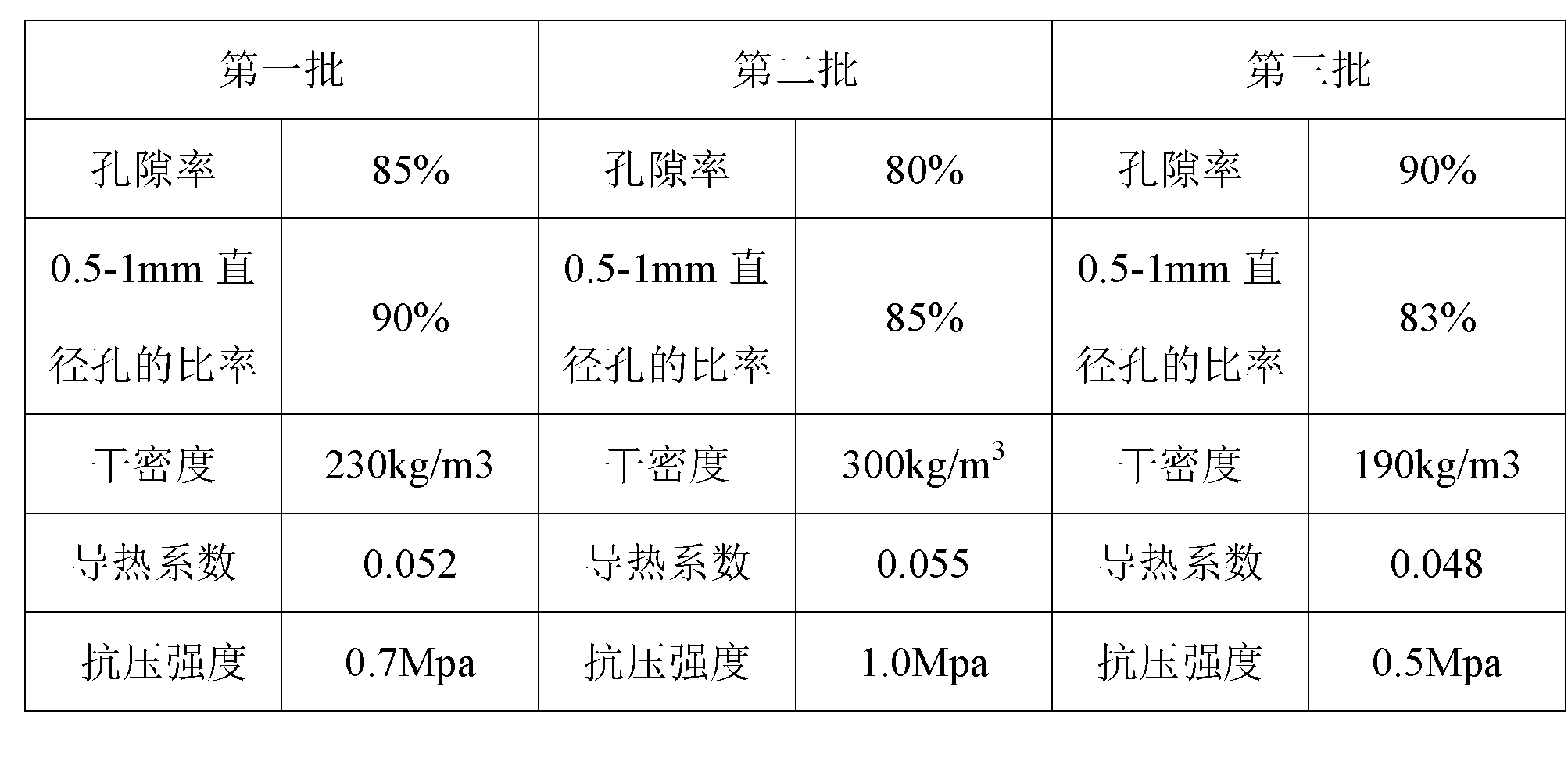

Embodiment 1

[0025] 1) Cement slurry preparation: 0.75kg of ordinary portland cement, 1.3kg of sulphoaluminate cement, 0.8kg of fly ash, 0.3kg of silica fume, dry mix for 2 minutes, add 1.3kg of water, 0.3kg of expansion agent, 0.01kg Coagulation accelerator, 0.005kg water reducing agent, 0.005kg water repellent and stir for 3 minutes, slowly add 0.03kg fiber and stir for 2 minutes.

[0026] 2) Foam preparation: Mix 5kg of foaming agent, 0.01kg of foam stabilizer and 150kg of water evenly, transfer it into a foaming machine, and prepare uniform and stable foam in the foaming machine.

[0027] 3) Mix the cement paste and foam in a mixer for 5 minutes at a volume ratio of 0.15:0.85 until evenly mixed.

[0028] 4) Pour the prepared foam cement into the mold made of insulation board, cover the mold with insulation board after pouring, remove the mold after 10 hours, cut it, and heat preservation and maintenance.

[0029] The temperature of the water used in the preparation of the inorganic fo...

Embodiment 2

[0031] 1) Cement slurry preparation: 1kg of ordinary Portland cement, 1kg of sulphoaluminate cement, 0.5kg of fly ash, 0.2kg of silica fume, dry mix for 1 minute, add 1kg of water, 0.25kg of expansion agent, and 0.01kg of coagulation accelerator Agent, 0.005kg water reducing agent, 0.005kg water repellent and stir for 4 minutes, slowly add 0.02kg fiber and stir for 3 minutes.

[0032] 2) Preparation of foam: Mix 5kg of foaming agent, 0.025kg of foam stabilizer and 125kg of water evenly, transfer it into a foaming machine, and prepare uniform and stable foam in the foaming machine.

[0033] 3) Mix the cement paste and foam in a mixer for 10 minutes at a volume ratio of 0.2:0.8 until evenly mixed.

[0034] 4) Pour the prepared foam cement into the mold made of insulation board, cover the mold with insulation board after pouring, remove the mold after 36 hours, cut it, and heat preservation and maintenance.

[0035] The water temperature of the water used in the preparation of t...

Embodiment 3

[0037] 1) Preparation of cement paste: Dry mix 2kg of ordinary Portland cement, 0.7kg of fly ash, and 0.15kg of silica fume for 2 minutes, add 1.3kg of water, 0.2kg of expansion agent, and 0.02kg of lithium silicate-containing composite coagulation accelerator Agent, 0.005kg water reducing agent, 0.004kg water repellent and stir for 4 minutes, slowly add 0.03kg fiber and stir for 3 minutes.

[0038] 2) Preparation of foam: Mix 5kg of foaming agent, 0.05kg of foam stabilizer and 150kg of water evenly, transfer it into a foaming machine, and prepare uniform and stable foam in the foaming machine.

[0039] 3) Mix the cement paste and foam in a mixer for 10 minutes at a volume ratio of 0.1:0.9 until evenly mixed.

[0040] 4) Pouring the prepared foam cement into the mold made of insulation board, covering the mold with insulation board after pouring, removing the mold after 72 hours, cutting, heat preservation and maintenance.

[0041] The water temperature of the water used in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com