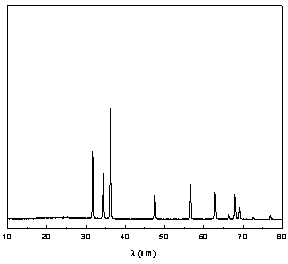

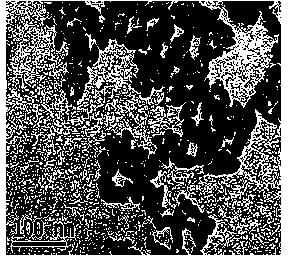

Method for synthesizing nano-zinc oxide by micro-emulsion carbon black adsorption precipitation method

A nano-zinc oxide, adsorption and precipitation technology, which is applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of increasing the particle size of nanoparticles and asynchronous process of precipitation reaction, etc., and achieve low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Dissolve 0.136 g of zinc chloride in 0.1 mol / L hydrochloric acid solution to prepare 10 mL of zinc chloride solution with a concentration of 0.1 mol / L to obtain solution A;

[0023] (2) Dissolve 0.6 g of cetyltrimethylammonium bromide CTAB in 200 mL of cyclohexane to obtain solution B, measure 5 mL of solution A, slowly add it to solution B, stir, and simultaneously add 7 mL of n-butyl Alcohol until the system changes from a milky white opaque emulsion to a colorless, clear and stable microemulsion, then measure 0.024 g of carbon black, add it to the cyclohexane system, continue to stir and ultrasonically oscillate for a total of 2 hours to obtain a mixed system C;

[0024] (3) Dissolve 0.6g of cetyltrimethylammonium bromide CTAB in 200mL of cyclohexane, add dropwise 8ml of ammonia solution with a concentration of 0.3 mol / L prepared with concentrated ammonia water, and add dropwise 7 mL of n-butyl Alcohol to the system from milky white opaque emulsion to colorless, ...

Embodiment 2

[0027] (1) Dissolve 0.34 g of zinc chloride in 0.05mol / L hydrochloric acid solution to prepare 50 mL of 0.05mol / L zinc chloride solution to obtain solution A;

[0028] (2) Dissolve 0.7 g of cetyltrimethylammonium bromide CTAB in 190 mL of cyclohexane to obtain solution B, measure 7 mL of solution A, slowly add it to solution B, stir, and simultaneously add 8 mL of n-butyl Alcohol until the system changes from a milky white opaque emulsion to a colorless, clear and stable microemulsion, then weigh 0.0168 g of carbon black, add it to the cyclohexane system, continue to stir and ultrasonically oscillate for a total of 2 hours to obtain a mixed system C;

[0029] (3) Dissolve 0.7g of cetyltrimethylammonium bromide CTAB in 190mL of cyclohexane, add dropwise 8ml of ammonia solution with a concentration of 0.3 mol / L prepared with concentrated ammonia water, and add dropwise 8 mL of n-butyl Alcohol to the system from milky white opaque emulsion to colorless, clear and stable microemul...

Embodiment 3

[0032] (1) Dissolve 0.109 g of zinc chloride in 0.1 mol / L hydrochloric acid solution to prepare 10 ml of 0.08 mol / L zinc chloride solution to obtain solution A;

[0033] (2) Dissolve 0.8 g of cetyltrimethylammonium bromide CTAB in 210 mL of cyclohexane to obtain solution B, measure 8 mL of solution A, slowly add it to solution B, stir, and drop 9 mL of n-butyl Alcohol until the system changes from a milky white opaque emulsion to a colorless, clear and stable microemulsion, then weigh 0.0307 g of carbon black, add it to the cyclohexane system, continue to stir and ultrasonically oscillate for a total of 2 hours to obtain a mixed system C;

[0034] (3) Dissolve 0.8g of cetyltrimethylammonium bromide CTAB in 210mL of cyclohexane, add dropwise 9 ml of ammonia solution with a concentration of 0.3 mol / L prepared with concentrated ammonia water, and add dropwise 9 mL of Butanol to system from milky white opaque emulsion to colorless, clear and stable microemulsion D;

[0035] (4) M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com