A method for producing sulfuric acid and calcium oxide by decomposing gypsum

A technology of calcium oxide and calcium sulfate, which is applied in chemical instruments and methods, sulfur compounds, calcium/strontium/barium oxides/hydroxides, etc., can solve the problem of various production raw materials, large fluctuations in kiln gas concentration, and uneven cement clinker. Stability and other issues, to achieve the effect of large-scale industrial production, easy control of the reaction atmosphere, and stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

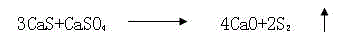

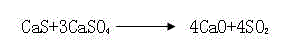

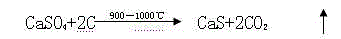

Method used

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

[0032] (1) After drying and dewatering the desulfurized gypsum of coal power plant containing 10wt% of external moisture, the moisture content is 6wt%, and the desulfurized gypsum and coke powder after dehydration are mixed with a mass ratio of 100:5, and then sent into FRMS vertical mill is mixed and ground, the fineness is 0.08mm standard sieve, and the sieve residue is 20wt%;

[0033] (2) The raw materials prepared in step (1) are sent to the suspension preheater and exchange heat with the 750℃ kiln gas from the tail of the rotary kiln to preheat the raw materials to 600℃, and the kiln gas leaves the suspension preheater. The temperature is 300-350℃;

[0034] (3) The raw materials preheated in step (2) are sent to the rotary kiln for calcination and decomposition. At 900-1250°C, the kiln is controlled to have a weak oxidizing atmosphere, and the pulverized coal combustion air excess coefficient is 1.04, and the kiln tail gas ...

Embodiment 2

[0038] The calcium sulfate in this embodiment is derived from the phosphogypsum produced in the production of wet-process phosphoric acid, and its external moisture is 15wt%. The mass ratio of the phosphogypsum to the coke powder after drying and dehydration is 100:6. Other steps and embodiments 1 is the same.

Embodiment 3

[0040] The raw material used in this embodiment is crushed natural anhydrite with a lumpiness ≤25mm. The natural anhydrite powder is directly blended. The crushed natural anhydrite and coke powder are blended with a mass ratio of 100:8, and the coke powder The grinding was carried out together, and the others were the same as in Example 1.

[0041] When natural anhydrite is used as the raw material, in step (3), the obtained kiln gas has a higher concentration and contains SO 2 10-12wt%, beneficial to the preparation of sulfuric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com