Iron-based sub-microcrystal alloy material for soft magnetic thin strip and preparation method of iron-based sub-microcrystal alloy material

An alloy material and soft magnetic technology, which is applied in the field of iron-based submicrocrystalline soft magnetic thin strip alloy material and its preparation, can solve the problems of low coercive force, high cost, and complicated preparation process, so as to reduce internal stress and improve toughness , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

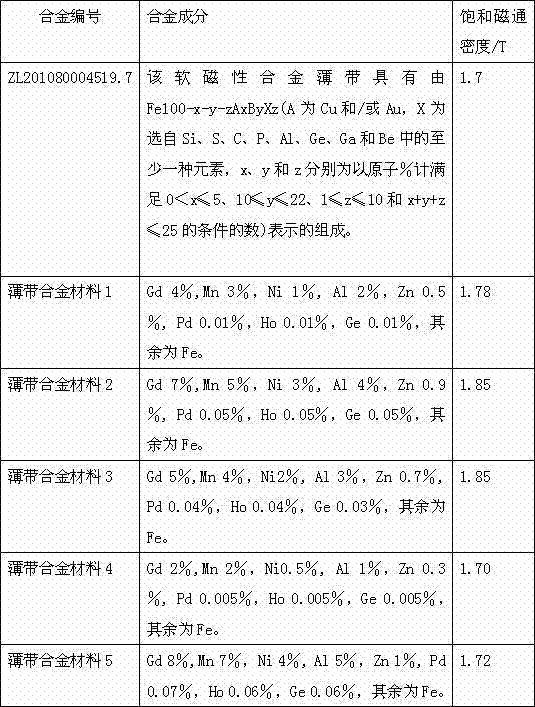

[0021] Example 1 Fe-based submicrocrystalline soft magnetic ribbon alloy material

[0022] Recipe 1

[0023] The components and their weight percentages are as follows: Gd 4%, Mn 3%, Ni 1%, Al 2%, Zn 0.5%, Pd 0.01%, Ho 0.01%, Ge 0.01%, and the rest is Fe.

[0024] Recipe 2

[0025] The components and their weight percentages are as follows: Gd 7%, Mn 5%, Ni 3%, Al 4%, Zn 0.9%, Pd 0.05%, Ho 0.05%, Ge 0.05%, and the rest is Fe.

[0026] Recipe 3

[0027] The components and their weight percentages are as follows: Gd 5%, Mn 4%, Ni 2%, Al 3%, Zn 0.7%, Pd 0.04%, Ho 0.04%, Ge 0.03%, and the rest is Fe.

[0028] Recipe 4

[0029] The components and their weight percentages are as follows: Gd 2%, Mn 2%, Ni 0.5%, Al 1%, Zn 0.3%, Pd 0.005%, Ho 0.005%, Ge 0.005%, and the rest is Fe.

[0030] Recipe 5

[0031] The components and their weight percentages are as follows: Gd 8%, Mn 7%, Ni 4%, Al 5%, Zn 1%, Pd 0.07%, Ho 0.06%, Ge 0.06%, and the rest is Fe.

[0032] Wherein formula 4 an...

Embodiment 2

[0033] Embodiment 2 The preparation method of iron-based submicrocrystalline soft magnetic strip alloy material

Embodiment 1

[0034] Five kinds of formulas among the embodiment 1 all can adopt following method to prepare:

[0035] Method one:

[0036] According to the alloy composition, the purity of the raw materials Mn, Ni, Al, Zn, Pd, Ho, Ge, Fe is greater than 99.9%, Gd is added in the form of iron-gadolinium alloy, and the weight percentage of Gd in the iron-gadolinium alloy is 35%;

[0037] Put the prepared materials of each formula into a vacuum induction furnace for melting, the melting temperature is 1540°C, and the master alloy is obtained after pouring and cooling;

[0038] The remelting tubular crucible is placed in a vacuum induction forming furnace, and its top is placed 3 mm below the runner rim of the vacuum induction forming furnace. A refractory plunger that can move up and down is placed in the remelting tubular crucible, The gap between the refractory plunger and the inner wall of the remelting tubular crucible is 0.7mm. The master alloy is placed on the top of the refractory plu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com