Loaded type molybdenum oxide catalyst for selectively oxidizing methanol to synthesize dimethoxymethane (DMM) and application

A dimethoxymethane, oxidation synthesis technology, applied in the direction of organic compound / hydride / coordination complex catalyst, physical / chemical process catalyst, organic compound preparation, etc., can solve the problem of harsh reaction conditions and achieve the preparation The effect of simple process, low energy consumption and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

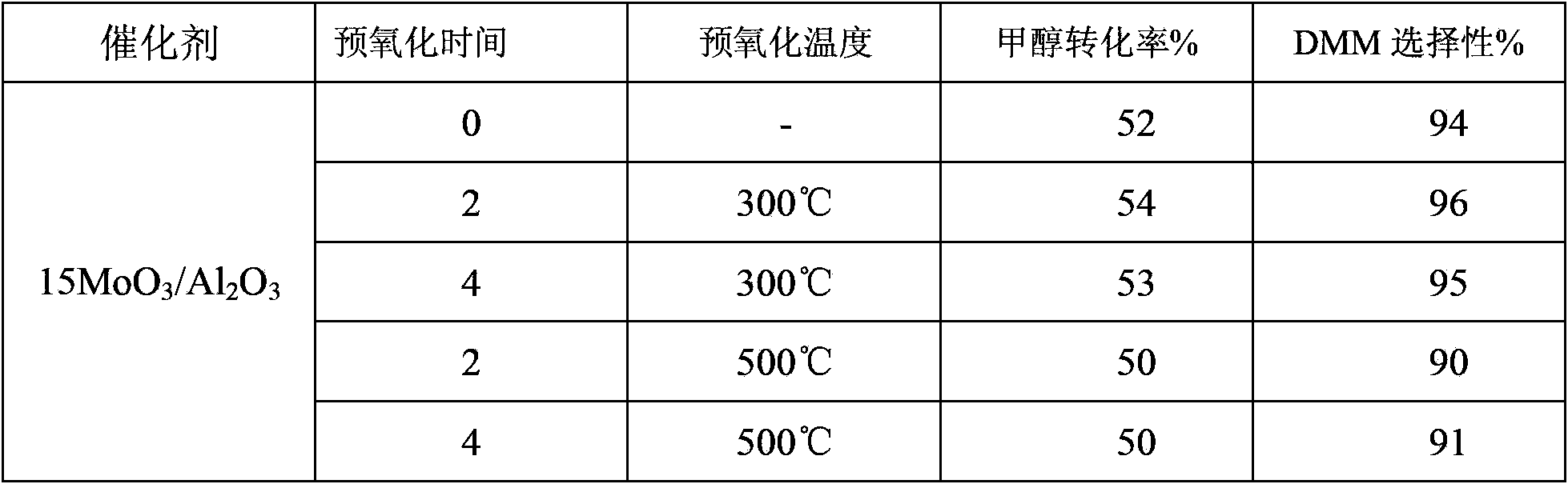

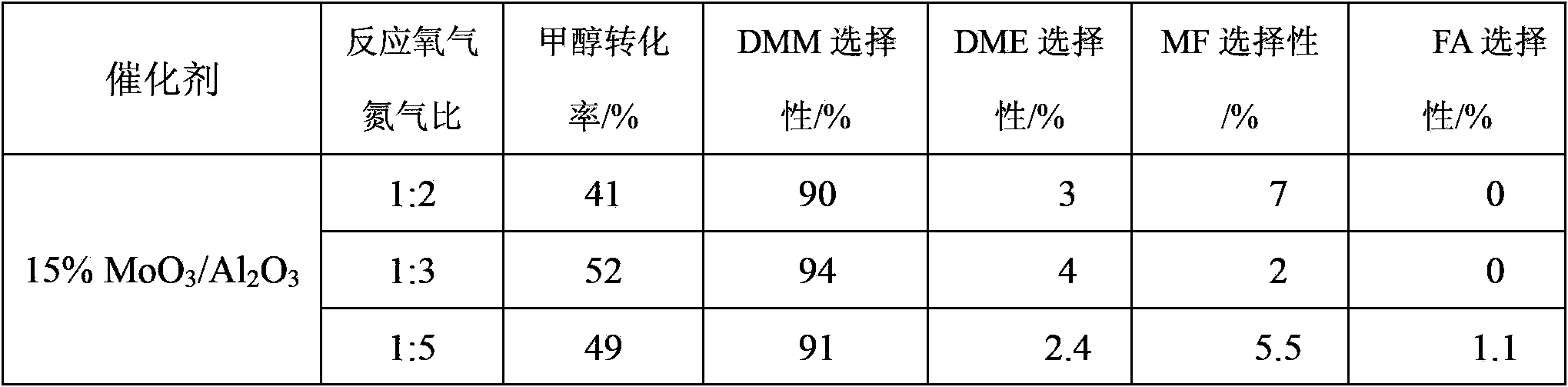

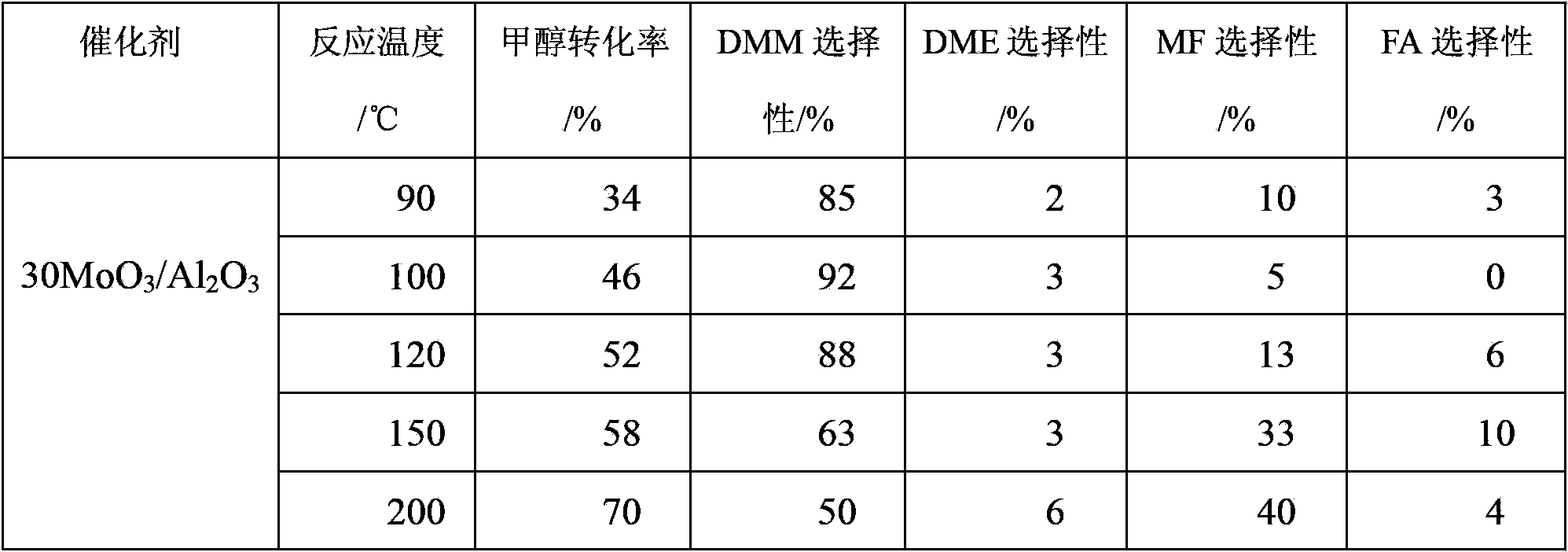

Embodiment 1

[0026] The catalytic reaction is carried out in a fixed bed reactor. Sieve the prepared catalyst tablet into 20-40 mesh (the particle size accounts for 1%-4% of the reactor diameter), weigh 0.3g (bed height / reactor bed diameter=0.5) into 8mm inner diameter quartz In the reaction tube, the catalyst is pretreated at 100-500° C. for 0-4 hours in an oxygen atmosphere. Nitrogen is passed first, and then oxygen and methanol are passed through. The raw material methanol is fed by bubbling at low temperature (15°C). 2 The flow rate is 9ml / min, the reaction temperature is 100°C, the reaction pressure is normal pressure, and the reaction time is 8 hours. o 2 / N 2 =1:3, the ratio of oxygen to methanol is 2.5:1, and the total volume space velocity is 8000h -1 . The composition of the reaction product was analyzed by gas chromatography, and the conversion of methanol and the selectivity of dimethoxymethane (DMM) were calculated.

Embodiment 2

[0028] The reaction was carried out using the method of Example 1, except that the catalyst was pre-oxidized at 300° C. for 2 hours before the reaction.

Embodiment 3

[0030] The reaction was carried out using the method of Example 1, the difference being that the pre-oxidation temperature was changed to 500° C. for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com