Electrode structure for capacitor, process for producing same, and capacitor including the electrode structure

A manufacturing method and capacitor technology, applied in hybrid capacitor electrodes, hybrid capacitor current collectors, hybrid/electric double-layer capacitor manufacturing, etc., can solve problems such as increased internal resistance, achieve internal resistance reduction, inhibit acid or alkali corrosion, Effect of reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

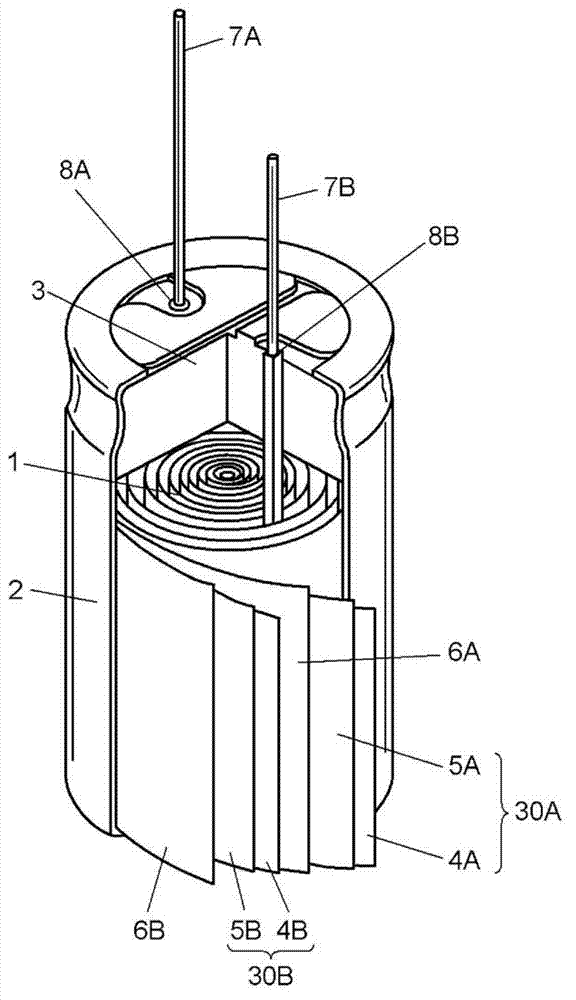

[0021] figure 1 It is a partially cutaway perspective view of a capacitor using the capacitor electrode assembly according to the embodiment of the present invention. First, edge reference figure 1 , an example of a capacitor using the capacitor electrode assembly of the present embodiment will be described. This capacitor has a capacitor element 1 , an electrolytic solution (not shown) impregnated at least in the capacitor element 1 , a case 2 , and a sealing member 3 .

[0022] The bottomed cylindrical case 2 is made of aluminum. The case 2 accommodates the capacitor element 1 and the electrolytic solution. A sealing member 3 made of rubber is fitted into the opening of the case 2 . That is, the sealing member 3 seals the opening of the case 2 . The vicinity of the opening end of the case 2 is constricted, and the case 2 is firmly sealed by compressing the sealing member 3 inwardly. The case 2 and the sealing member 3 constitute an outer package for accommodating the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com