Cascading inductor based on metal magnetic slurry and preparation method thereof

A metal magnetic, stacked inductance technology, used in the manufacture of inductors/transformers/magnets, inductors, magnetic materials, etc., can solve the problems of high DC resistance, low rated current, etc., to improve saturation magnetization, reduce DC resistance, improve Effect of rated current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

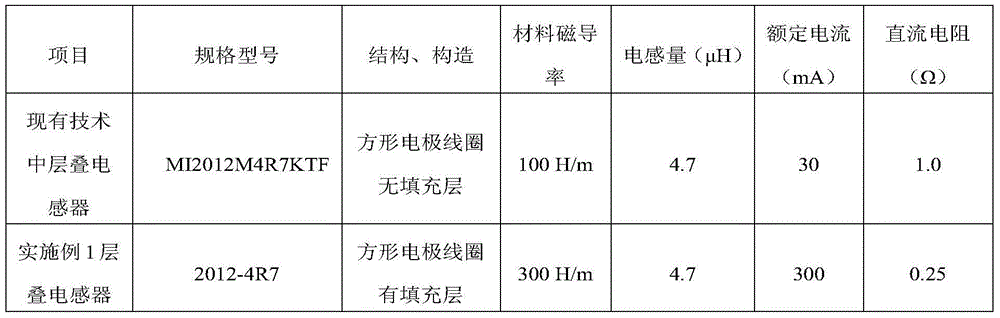

Embodiment 1

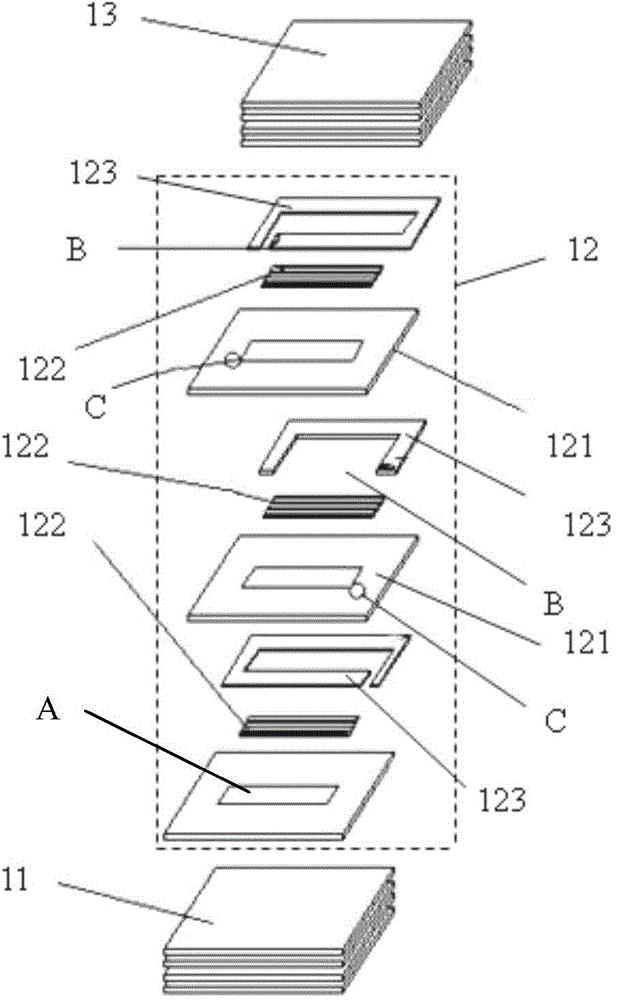

[0042] A laminated inductor based on metal magnetic paste, see figure 1 , specifically including the first substrate 11, the intermediate layer 12 and the second substrate 13 arranged from bottom to top, the intermediate layer 12 includes three single layers arranged from bottom to top, and the number of single layers can also be selected according to actual needs.

[0043] The single layer of the first layer includes a dielectric layer 121, a filling layer 122 and a coil electrode 123, and the dielectric layer 121 is provided with a through hole A along the up and down direction (the through hole A is preferably located in the dielectric layer 121 and the area of the through hole A on the upper surface of the dielectric layer 121 is 0.1-0.8 times the area of the upper surface of the dielectric layer 121); the filling layer 122 is arranged on the through hole Place A, the thickness of the filling layer 122 along the vertical direction is the same as the thickness of the di...

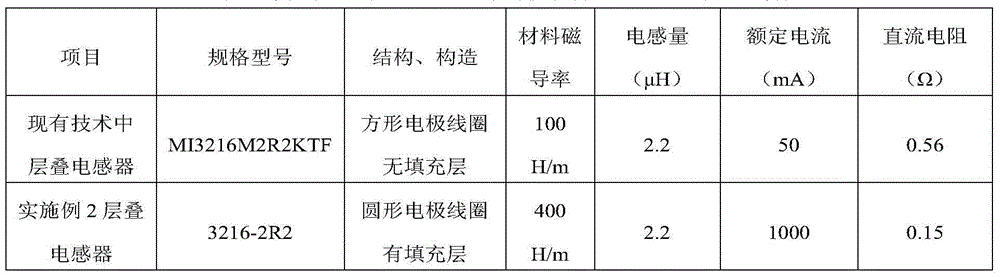

Embodiment 2

[0062] A laminated inductor based on metal magnetic paste, which differs from Embodiment 1 only in that: (1) the formulation of the filling layer 122 is different; (2) the preparation method is different.

[0063] The filling layer 122 in this embodiment includes the following substances in parts by weight: 7 parts of inorganic powder composed of metal magnetic powder, 1 part of lead-free glass powder, 1 part of organic vehicle and additives 1 serving. The lead-free glass powder includes the following materials in parts by weight: 2 parts of lithium oxide, 2 parts of potassium oxide, 15 parts of diboron trioxide, 15 parts of bismuth oxide and 45 parts of silicon dioxide. The organic vehicle includes the following materials in parts by weight: 15 parts of butyl carbitol, 5 parts of terpineol and 3 parts of ethyl cellulose. The auxiliary agent includes the following substances in parts by weight: 1 part of triethanolamine, 1 part of triethylene glycol diisocaprylate, 2 parts of...

Embodiment 3

[0072] A laminated inductor based on metal magnetic paste, which differs from Embodiment 1 only in that: (1) the formulation of the filling layer 122 is different; (2) the preparation method is different.

[0073] The filling layer 122 in this embodiment includes the following substances in parts by weight: 7 parts of inorganic powder composed of metal magnetic powder, 1 part of lead-free glass powder, 1.5 parts of organic vehicle and additives 1.5 servings. The lead-free glass powder includes the following materials in parts by weight: 3 parts of lithium oxide, 3 parts of potassium oxide, 20 parts of diboron trioxide, 20 parts of bismuth oxide and 40 parts of silicon dioxide. The organic vehicle includes the following materials in parts by weight: 10 parts of butyl carbitol, 15 parts of terpineol and 2 parts of binder. The auxiliary agent includes the following substances in parts by weight: 2 parts of triethanolamine, 2 parts of triethylene glycol diisocaprylate, 1 part of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com