Colored photosensitive resin composition

A technology of photosensitive resin and composition, applied in optics, opto-mechanical equipment, photo-engraving process exposure devices, etc., can solve the problems of peeling and peeling foreign matter, and achieve the effect of inhibiting peeling and reducing foreign matter on the pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0267] Next, examples will be given to describe the present invention more specifically. Unless otherwise specified, "%" and "part" in an example are mass % and a mass part.

Synthetic example 1

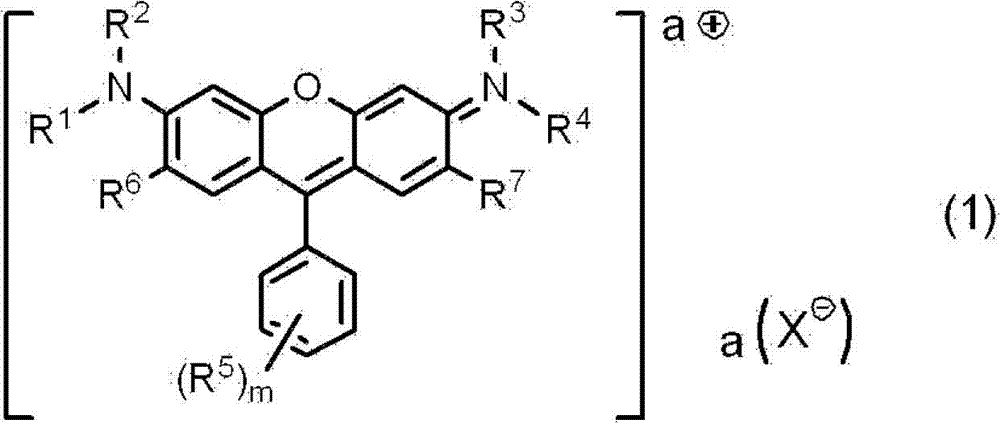

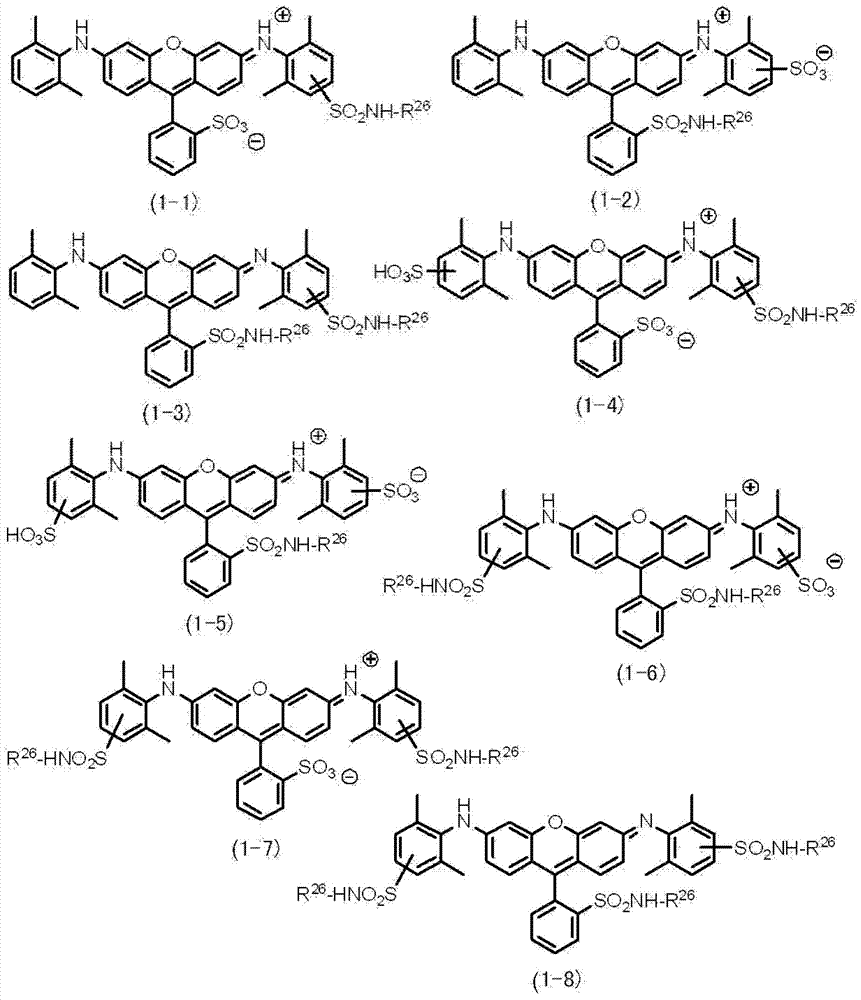

[0269] Put 15 parts of the mixture of the compound shown in formula (A0-1) and the compound shown in formula (A0-2) (manufactured by Zhonggai Chemicals), 150 parts of chloroform and N, N-dimethyl in a flask equipped with a cooling tube and a stirring device 8.9 parts of methyl formamide were kept below 20°C under stirring, while 10.9 parts of thionyl chloride were added dropwise. After completion of the dropwise addition, it was heated to 50°C, maintained at the same temperature for 5 hours to allow a reaction, and then cooled to 20°C. While maintaining the cooled reaction solution at 20° C. or lower while stirring, a mixed solution of 12.5 parts of 2-ethylhexylamine and 22.1 parts of triethylamine was added dropwise. Thereafter, it was stirred at the same temperature for 5 hours to make it react. Next, after the obtained reaction mixture was subjected to solvent distillation using a rotary evaporator, a small amount of methanol was added and vigorously stirred. This mixture...

Synthetic example 2

[0273] Into a flask equipped with a stirrer, a thermometer, a reflux condenser, and a dropping funnel, nitrogen gas was flowed at 0.02 L / min to obtain a nitrogen atmosphere, 184 parts by mass of ethyl lactate were charged, and heated to 70° C. while stirring. Next, 167 parts by mass of methacrylic acid and 3,4-epoxytricyclo[5.2.1.0 2.6 ] Decyl acrylate (mix the compound represented by the following formula (I-1) and the compound represented by formula (II-1) at a molar ratio of 50:50.) 284 parts by mass were dissolved in 140 parts by mass of ethyl lactate to prepare The solution was dropped into a flask kept at 70° C. using a dropping funnel over a period of 4 hours. On the other hand, 30 parts by mass of the polymerization initiator 2,2'-azobis(2,4-dimethylvaleronitrile) dissolved in ethyl lactate was dropped into the flask over 4 hours using another dropping funnel. A solution of 225 parts by mass of ester. After the dropwise addition of the solution of the polymerization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com