Synthetic aqueous quenching liquid and use method thereof

A quenching liquid and water-based technology, applied in the field of quenching cooling medium, can solve the problems of slow cooling speed of oil products, poor quenching effect, fast cooling speed, etc., and achieve the effect of no fire hazard, not easy to aging, and deep hardened layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] In the synthetic water-based quenching liquid of the present embodiment, the lubricating oil raw material comprises the following components by weight percentage: 85% composite PAG, 13% urging agent, 2% antioxidant;

[0015] In this example, the composite PAG is a composite of polyoxyethylene polyoxypropylene ether R (C2H4O) X (C3H6O) YH SDN20 and polyoxyethylene polyoxypropylene ether R (C2H4O) X (C3H6O) YH SDN45;

[0016] In this embodiment, the refrigerant is polyoxyethylene polyoxypropylene ether R (C2H4O) X (C3H6O) YHSDN165;

[0017] The method of using the synthetic water-based quenching liquid in this embodiment is to dilute the synthetic water-based quenching liquid and water at a ratio of 1:7.

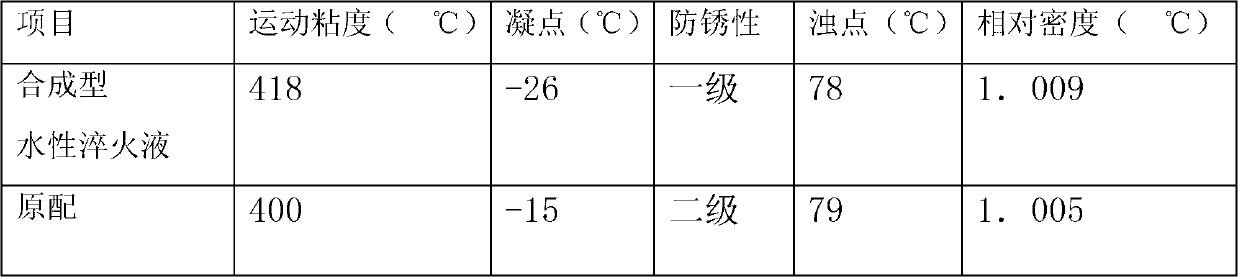

[0018] The performance parameter comparison table of the synthetic water-based quenching liquid of the present embodiment:

[0019]

Embodiment 2

[0021] In the synthetic water-based quenching liquid of this embodiment, the lubricating oil raw material comprises the following components by weight percentage: 80% composite PAG, 17% urging agent, 3% antioxidant;

[0022] In this example, the composite PAG is a composite of polyoxyethylene polyoxypropylene ether R (C2H4O) X (C3H6O) YH SDN20 and polyoxyethylene polyoxypropylene ether R (C2H4O) X (C3H6O) YH SDN45;

[0023] In this embodiment, the refrigerant is polyoxyethylene polyoxypropylene ether R (C2H4O) X (C3H6O) YHSDN165;

[0024] The method of using the synthetic water-based quenching liquid in this embodiment is to dilute the synthetic water-based quenching liquid and water at a ratio of 1:4 for use.

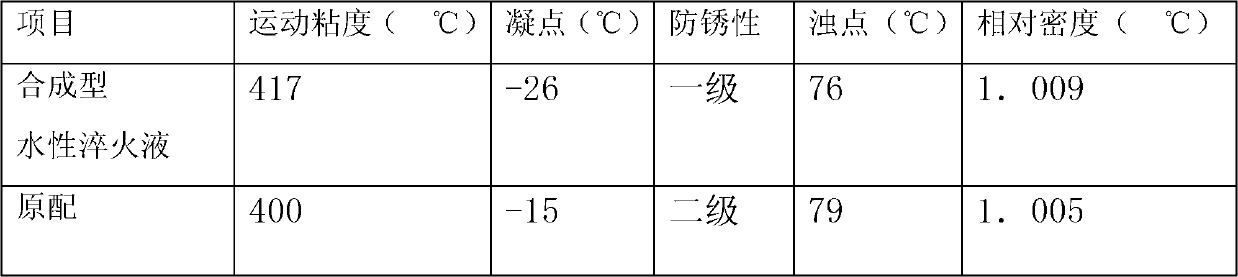

[0025] The performance parameter comparison table of the synthetic water-based quenching liquid of the present embodiment:

[0026]

Embodiment 3

[0028] In the synthetic water-based quenching liquid of the present embodiment, the lubricating oil raw material comprises the following components by weight percentage: 90% composite PAG, 18% urging agent, 2% antioxidant;

[0029] In this example, the composite PAG is a composite of polyoxyethylene polyoxypropylene ether R (C2H4O) X (C3H6O) YH SDN20 and polyoxyethylene polyoxypropylene ether R (C2H4O) X (C3H6O) YH SDN45;

[0030] In this embodiment, the refrigerant is polyoxyethylene polyoxypropylene ether R (C2H4O) X (C3H6O) YHSDN165;

[0031] The method of using the synthetic water-based quenching liquid in this embodiment is to dilute the synthetic water-based quenching liquid with water at a ratio of 1:10.

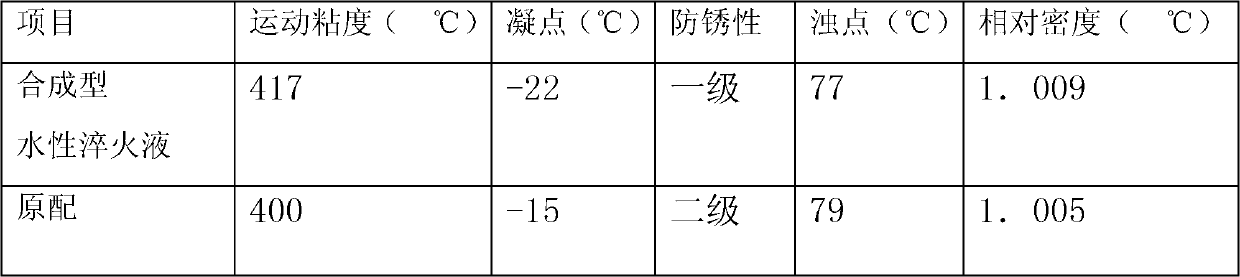

[0032] The performance parameter comparison table of the synthetic water-based quenching liquid of the present embodiment:

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com