Piezoelectric ceramic material and piezoelectric ceramic vibrator manufactured by same

A piezoelectric ceramic and piezoelectric ceramic sheet technology, applied in the field of material science, can solve the problems of short service life and high price, and achieve the effects of long service life, not easy to break and burn out, and improve service life and detection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 Piezoelectric ceramic material and preparation method of the present invention

[0048] The present invention provides a kind of new piezoelectric ceramic material, and the chemical formula of this piezoelectric ceramic material is Pb(Zn 1 / 3 Nb 2 / 3 ) 0.10 (Sn 1 / 3 Nb 2 / 3 ) 0.08 Ti 0.415 Zr 0.405 o 3 . Its main material composition and weight ratio are: trilead tetroxide (Pb 3 o 4 )67.9%, zirconia (ZrO 2 ) 15.0%, titanium oxide (TiO 2 )10.2%, niobium pentoxide (Nb 2 o 5 ) 4.76%, zinc oxide (ZnO) 0.74%, tin oxide (SnO 2 ) 1.4%. In addition, the piezoelectric ceramic material also contains 0.5-1.0% manganese carbonate (MnCO 3 ) and 0.4-0.6% antimony trioxide (Sb 2 o 3 ). The preparation method of the piezoelectric ceramic material is as follows:

[0049] 1) Ingredients: Trilead tetroxide, zirconium dioxide, titanium dioxide, niobium pentoxide, zinc oxide, manganese carbonate, antimony trioxide and tin oxide were dried separately, and weighed...

Embodiment 2

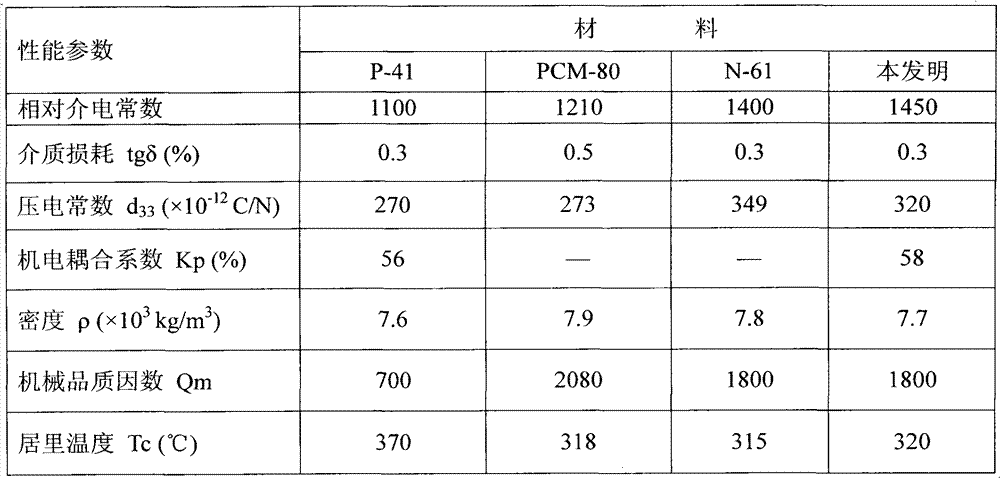

[0055] Embodiment 2 Performance comparison between the piezoelectric ceramic material of the present invention and the piezoelectric material of the prior art

[0056] The performance of piezoelectric materials determines the scope of use of piezoelectric materials, so the performance test of piezoelectric materials is a necessary step. Conventional performance test indicators mainly include dielectric loss, relative permittivity, electromechanical coupling coefficient, mechanical quality factor, piezoelectric constant, Curie temperature and other indicators. Its definition is as follows:

[0057] A. Dielectric loss refers to the energy loss caused inside the insulating material due to the hysteresis effect of dielectric conductance and dielectric polarization under the action of an electric field;

[0058] B. Relative permittivity: When the medium is applied with an electric field, it will generate induced charges and weaken the electric field. The ratio of the original appl...

Embodiment 3

[0079]Example 3 The piezoelectric ceramic vibrator prepared by using the piezoelectric ceramic material of the present invention and its preparation process

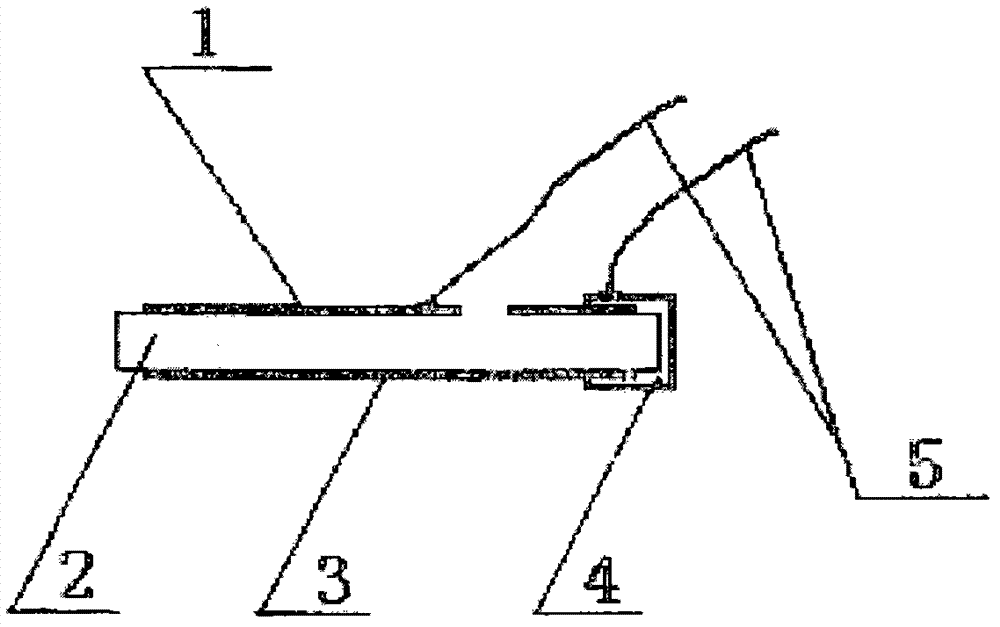

[0080] A piezoelectric ceramic vibrator prepared by using the above piezoelectric ceramic material, the piezoelectric ceramic vibrator includes the piezoelectric ceramic material described in Embodiment 1 and silver electrodes arranged on both sides of the piezoelectric ceramic material. Such as figure 1 As shown, the piezoelectric ceramic vibrator is composed of a piezoelectric ceramic material (piezoelectric ceramic sheet) 2, a silver electrode 1 and a silver electrode 3 arranged on the surface of the piezoelectric ceramic material, and a metal thin film 4 connecting the silver electrode 1 and the silver electrode 3 constitute, and the metal film 4 has a plating layer.

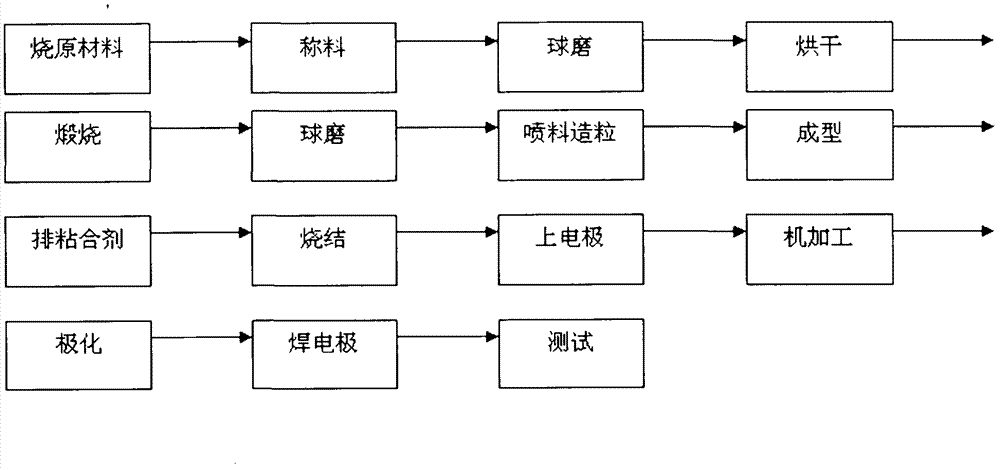

[0081] The preparation process of the piezoelectric ceramic vibrator is as follows: figure 2 As shown, the specific details are as follows:

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com