High-performance water reducer of polycarboxylic acid, and preparation method thereof

A high-performance, water-reducing agent technology, applied in the field of concrete admixtures in the construction industry, can solve the problems of difficult to meet concrete technology and requirements, poor slump retention, high alkali content, high water-reducing rate, low cost, Excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

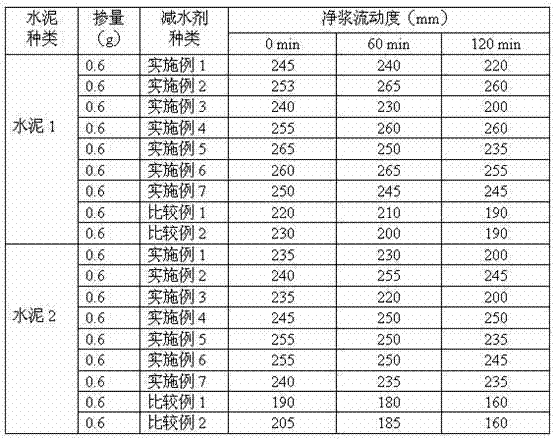

Examples

Embodiment 1

[0026] Embodiment 1: the preparation of polycarboxylate high-performance water reducing agent:

[0027] The present embodiment selects following raw material:

[0028] Methyl vinyl polyoxyethylene ether (TPEG) 300.0g

[0029] Acrylic acid 12.5g

[0030] Maleic anhydride 34.58g

[0031] Sodium methacrylate 21.08g

[0032] 3-mercaptopropionic acid 1.0g

[0033] Potassium peroxodisulfate 7.50g

[0034] The specific preparation method is:

[0035] First prepare the acrylic acid solution: the acrylic acid solution is made of 12.5g of acrylic acid, 1.0g of 3-mercaptopropionic acid and 70.5g of deionized water;

[0036] Then, in the glass reaction device equipped with thermometer, stirrer, peristaltic pump dropping equipment, nitrogen inlet pipe and reflux cooling device, add deionized water 400.0g, methyl alkenyl polyoxyethylene ether (TPEG) 300.0g, Malay Acid anhydride 34.58g, stir and heat up to 80°C, stir for 20 minutes until completely dissolved, add 21.08g of sodium meth...

Embodiment 2

[0037] Embodiment 2: the preparation of polycarboxylate high-performance water reducing agent:

[0038] The present embodiment selects following raw material:

[0039] Methyl vinyl polyoxyethylene ether (TPEG) 200.0g

[0040] Methoxy polyethylene glycol methacrylate (MAMPEG) 100g

[0041] Fumaric acid 34.58g

[0042] Acrylic acid 12.5g

[0043] Sodium methacrylate 3.5g

[0044] 3-mercaptopropionic acid 1.2g

[0045] L-Ascorbic Acid 0.96g

[0046] Potassium peroxodisulfate and hydrogen peroxide 8.8g

[0047] The specific preparation method is:

[0048] First prepare the initiator solution: made from 1.2 g of 3-mercaptopropionic acid, 0.96 g of L-ascorbic acid and 100 g of deionized water.

[0049] Acrylic acid solution: made of methoxypolyethylene glycol methacrylate (MAMPEG) 100g, acrylic acid 12.5g and deionized water 71.5g.

[0050] In the glass reaction device equipped with a thermometer, a stirrer, a peristaltic pump dropping device, a nitrogen gas introduction pi...

Embodiment 3

[0051] Embodiment 3: the preparation of polycarboxylate high-performance water reducing agent:

[0052]The present embodiment selects following raw material:

[0053] Methyl vinyl polyoxyethylene ether (TPEG) 300.0g

[0054] Citraconic acid 34.58g

[0055] Acrylic acid 12.5g

[0056] Sodium allyl sulfonate 19.21g

[0057] Hydroxyethyl Acrylate 9.5g

[0058] Thioglycolic acid 1.2g

[0059] Ammonium persulfate 9.25g

[0060] The specific preparation method is:

[0061] First prepare an acrylic acid solution: the acrylic acid solution is made of 12.5 g of acrylic acid, 9.5 g of hydroxyethyl acrylate, 1.2 g of thioglycolic acid and 70.5 g of deionized water.

[0062] In a glass reaction device equipped with a thermometer, a stirrer, a peristaltic pump dropping device, a nitrogen inlet pipe and a reflux cooling device, add 400.0 g of deionized water, 300.0 g of methyl alkenyl polyoxyethylene ether (TPEG), citraconic acid 34.58g, stirred and heated to 80°C, stirred for 20 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com