Method for preparing buried medium antenna

A technology for buried antennas and antennas in a medium, applied in the structural form of radiating elements and other directions, can solve problems such as difficulty, low yield and low melting point, and achieve the effects of reducing volume, improving yield and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

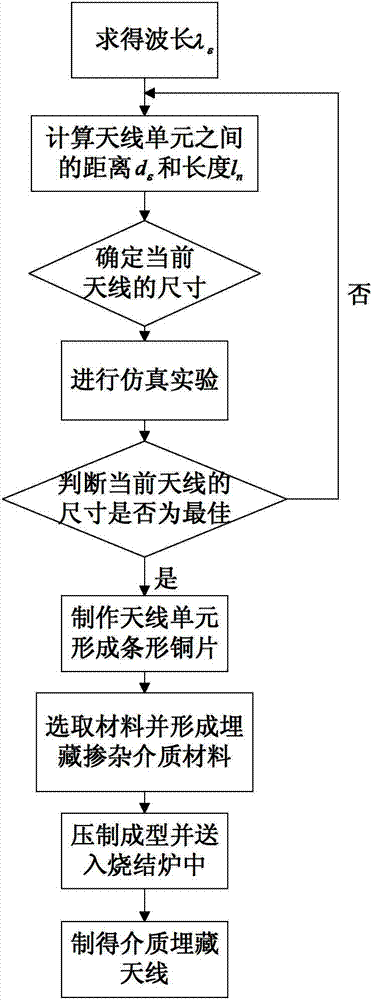

[0027] as attached figure 1 As shown, the present invention provides a method for preparing a dielectric buried antenna, the steps of which are as follows:

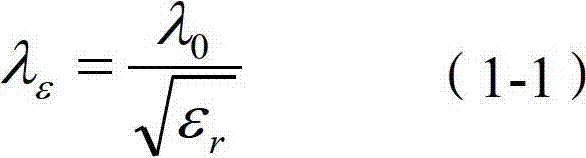

[0028] Step 1: Obtain the wavelength of the electromagnetic wave in the medium space according to the formula (1-1);

[0029] λ ϵ = λ 0 ϵ r - - - ( 1 - 1 )

[0030] Among them, λ 0 is the wavelength of the electromagnetic wave in free space (free space means the medium is air), λ ε is the wavelength of the electromagnetic wave in the medium space, ε r is the dielectric constant;

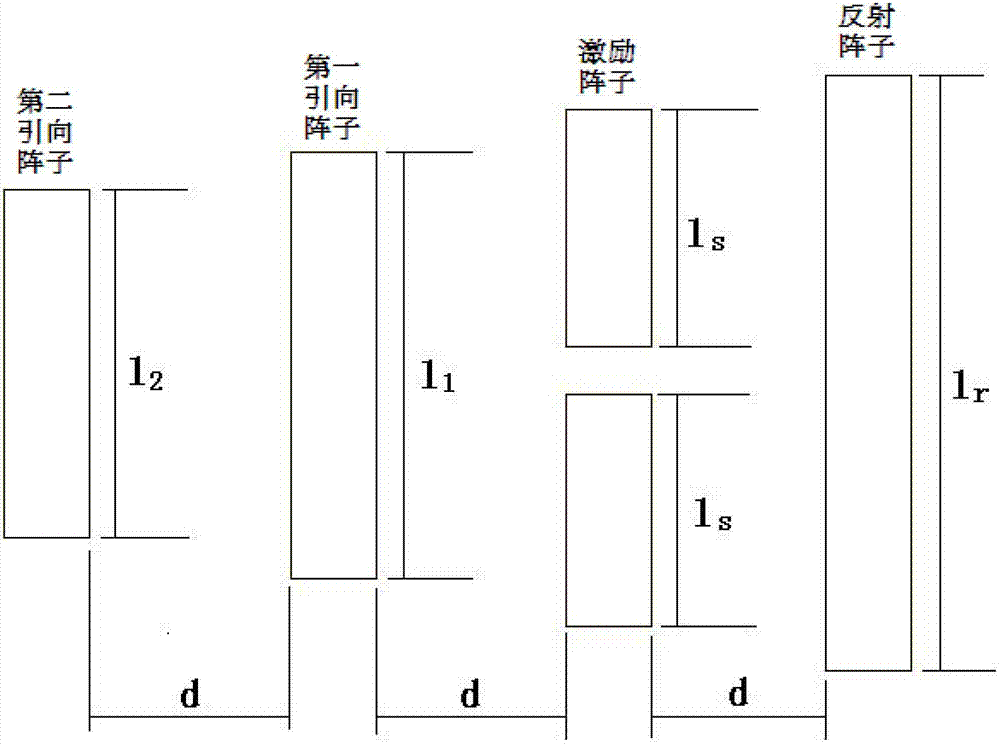

[0031] Step 2: The antenna is generally composed of several antenna units, and there is a certain distance between each antenna unit; according to the wavelength λ obtained in ...

Embodiment 1

[0047] Example 1: The mass ratio of the yttrium group rare earth to the barium bismuth oxide-based ceramic material is 1 / 1000, the temperature of the sintering furnace is controlled to 850° C. and after sintering for 3 hours, the temperature is artificially controlled and gradually cooled to obtain a dielectric buried antenna.

Embodiment 2

[0048] Example 2: The mass ratio of the yttrium group rare earth to the barium bismuth oxide-based ceramic material is 3 / 1000, the temperature of the sintering furnace is controlled at 860° C. and after sintering for 3.5 hours, the temperature is artificially controlled and gradually cooled to obtain a dielectric buried antenna.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com