A preparation method of antibacterial nylon powder for trolley coating

A nylon powder, trolley technology, applied in the field of nylon powder, can solve the problems of exposed inner layer, easy to be dirty, damage to human body, etc., and achieve the effect of excellent adhesion, excellent toughness and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

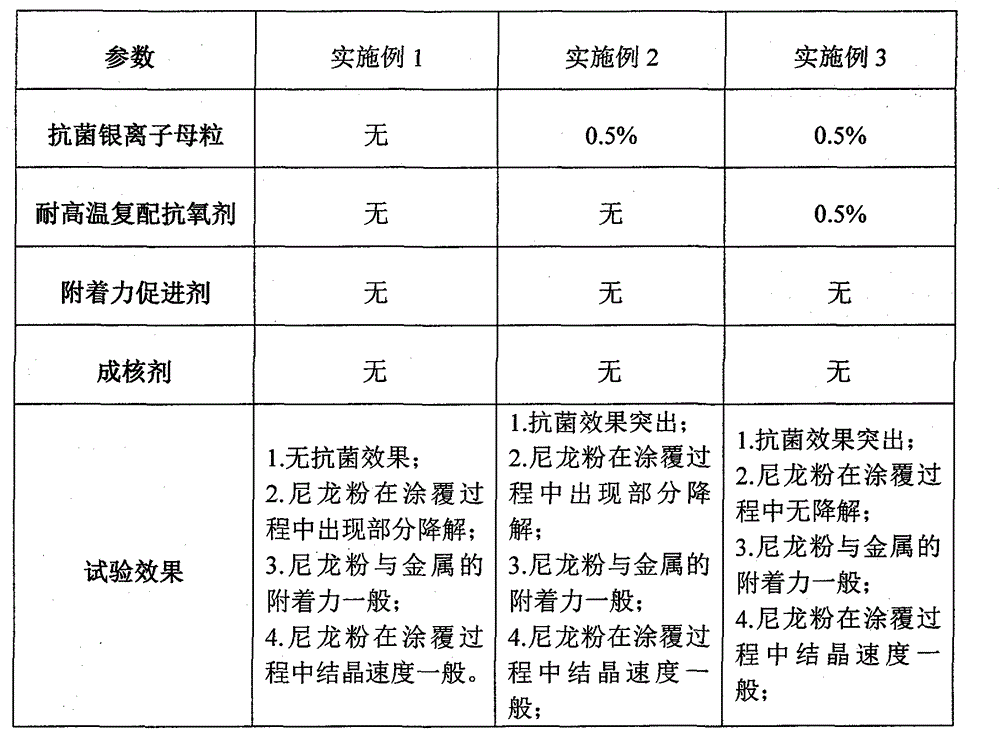

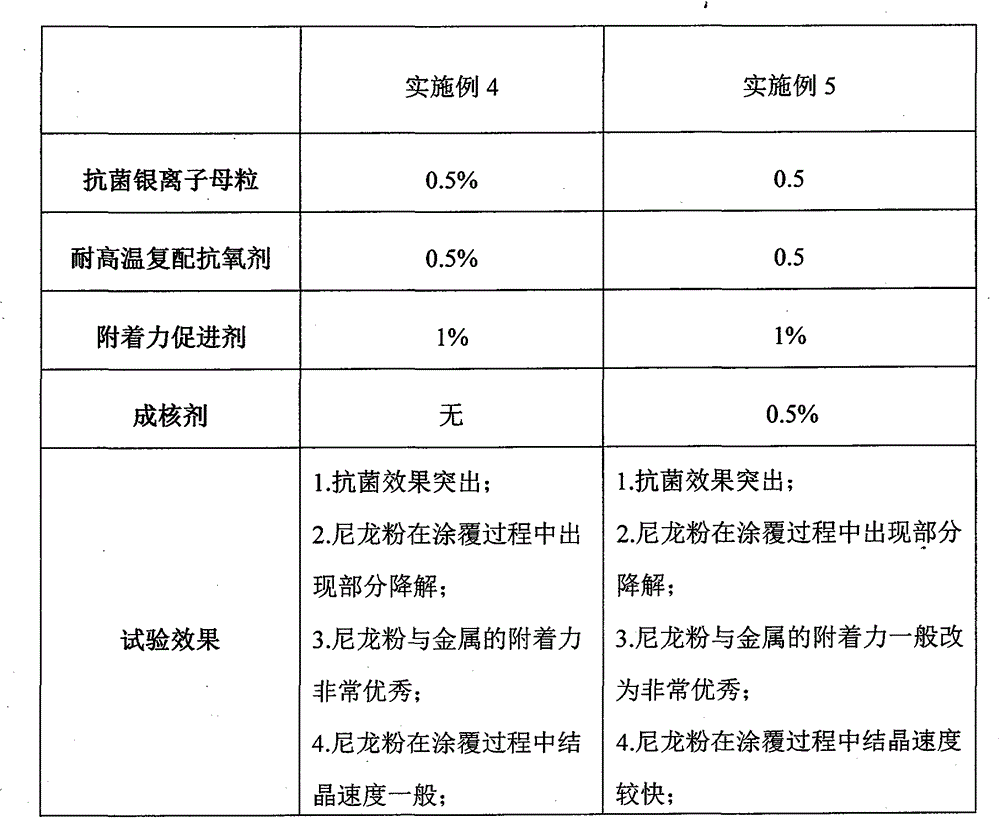

Examples

Embodiment 1

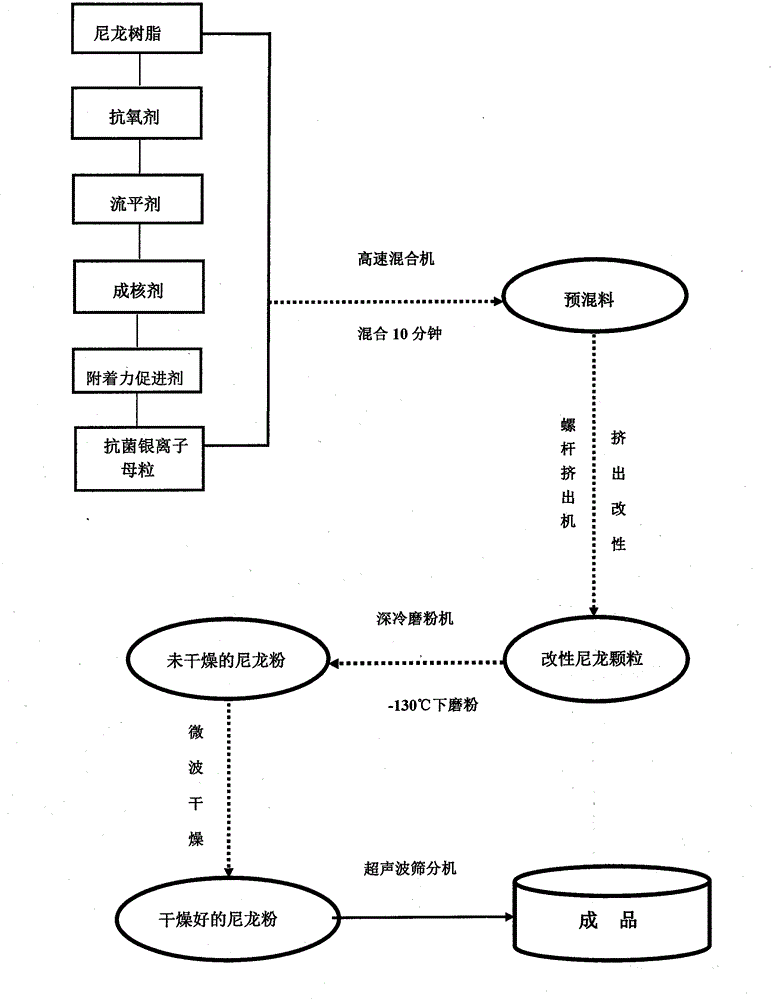

[0044] Such as figure 1 Shown:

[0045] 1. Modification of antibacterial nylon resin:

[0046] Mix every 100 kilograms of PA11 resin with 5 kilograms of organic fillers, 0.1 kilograms of ultraviolet stabilizers and 0.5 kilograms of leveling agents through high-speed stirring, and extrude and pelletize through a twin-screw extruder to obtain modified nylon resin particles;

[0047] 2. Preparation of antibacterial nylon powder

[0048] Grind the modified nylon resin into nylon powder through a cryogenic mill. When grinding the powder, first freeze the nylon resin to -130°C with liquid nitrogen and keep it for 30 minutes, and then grind the nylon particles into nylon through a disc mill. powder;

[0049] 3. Drying of antibacterial nylon powder

[0050] Pack and seal the ground nylon powder in a PE film-lined bag. After the nylon powder in the frozen state returns to normal temperature, the nylon powder is dried by a crawler-type microwave dryer. The moisture content of the dr...

Embodiment 2

[0054] 1. Modification of antibacterial nylon resin:

[0055] Mix every 100 kg of PA12 resin, 0.8 kg of antibacterial silver ion masterbatch, 5 kg of organic filler, 0.1 kg of ultraviolet stabilizer and 0.5 kg of leveling agent through high-speed stirring, and extrude and pelletize through a twin-screw extruder to obtain Modified nylon resin particles;

[0056] 2. Preparation of antibacterial nylon powder

[0057] Grind the modified nylon resin into nylon powder through a cryogenic mill. When grinding the powder, first freeze the nylon resin to -130°C with liquid nitrogen and keep it for 30 minutes, and then grind the nylon particles into nylon through a disc mill. powder;

[0058] 3. Drying of antibacterial nylon powder

[0059] Pack and seal the ground nylon powder in a PE film-lined bag. After the nylon powder in the frozen state returns to normal temperature, the nylon powder is dried by a crawler-type microwave dryer. The moisture content of the dried nylon powder is 0...

Embodiment 3

[0063] 1. Modification of antibacterial nylon resin:

[0064] Mix every 100 kg of PA1012 resin, 0.8 kg of antibacterial silver ion masterbatch, 5 kg of organic filler, 0.5 kg of high temperature resistant antioxidant, 0.1 kg of ultraviolet stabilizer and 0.5 kg of leveling agent through high-speed stirring, and extrude through twin-screw Machine extruded and pelletized to obtain modified nylon resin pellets;

[0065] 2. Preparation of antibacterial nylon powder

[0066] Grind the modified nylon resin into nylon powder through a cryogenic mill. When grinding the powder, first freeze the nylon resin to -130°C with liquid nitrogen and keep it for 30 minutes, and then grind the nylon particles into nylon through a disc mill. powder;

[0067] 3. Drying of antibacterial nylon powder

[0068] Pack and seal the ground nylon powder in a PE film-lined bag. After the nylon powder in the frozen state returns to normal temperature, the nylon powder is dried by a crawler-type microwave d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com