Making method of semi-flexible printed circuit board

A technology for printed circuit boards and manufacturing methods, which is applied in the fields of printed circuit manufacturing, printed circuits, electrical components, etc., and can solve problems such as high difficulty in process control, high cost, and complicated process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] The manufacturing method of the semi-flexible printed circuit board includes the following steps.

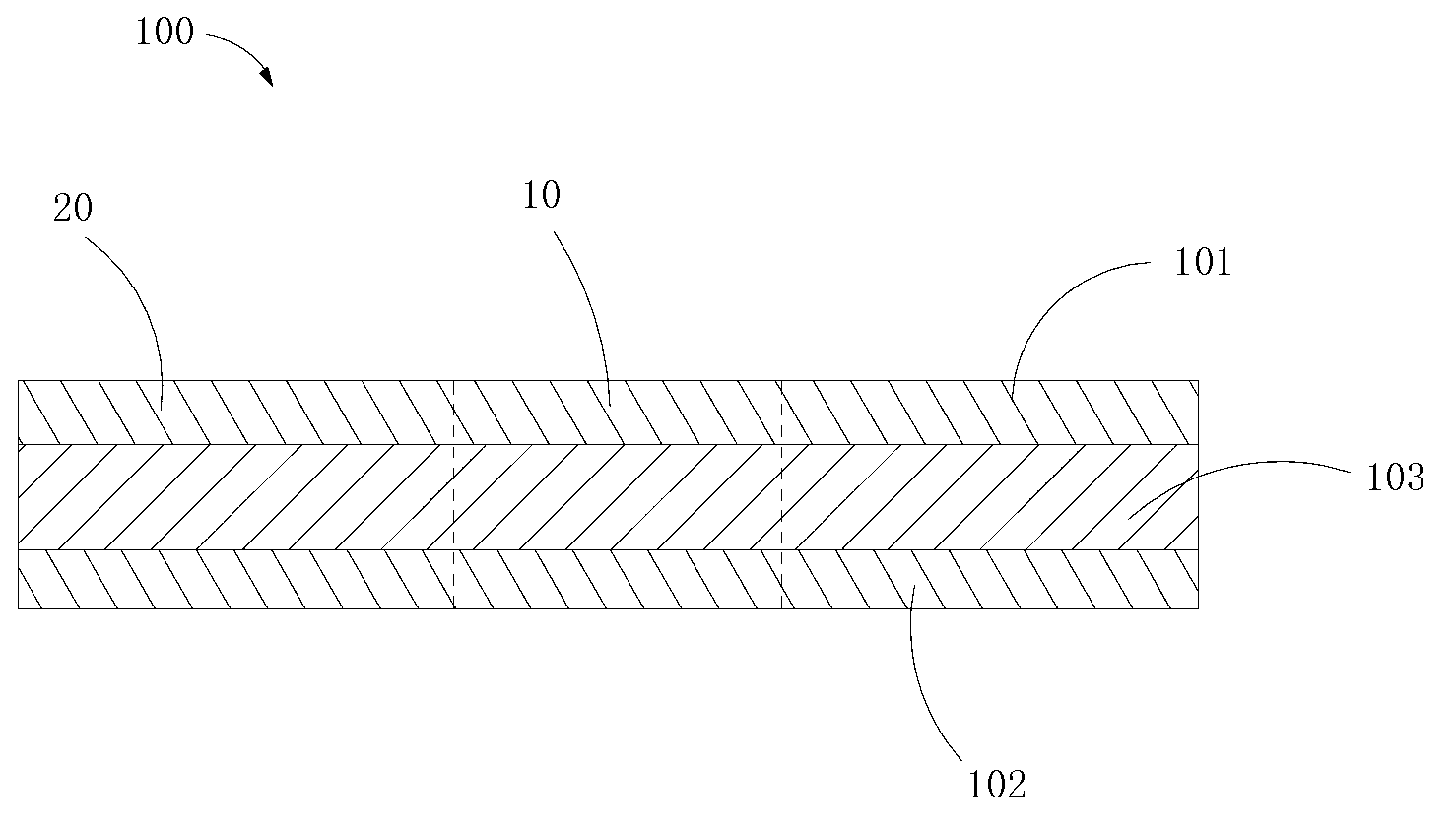

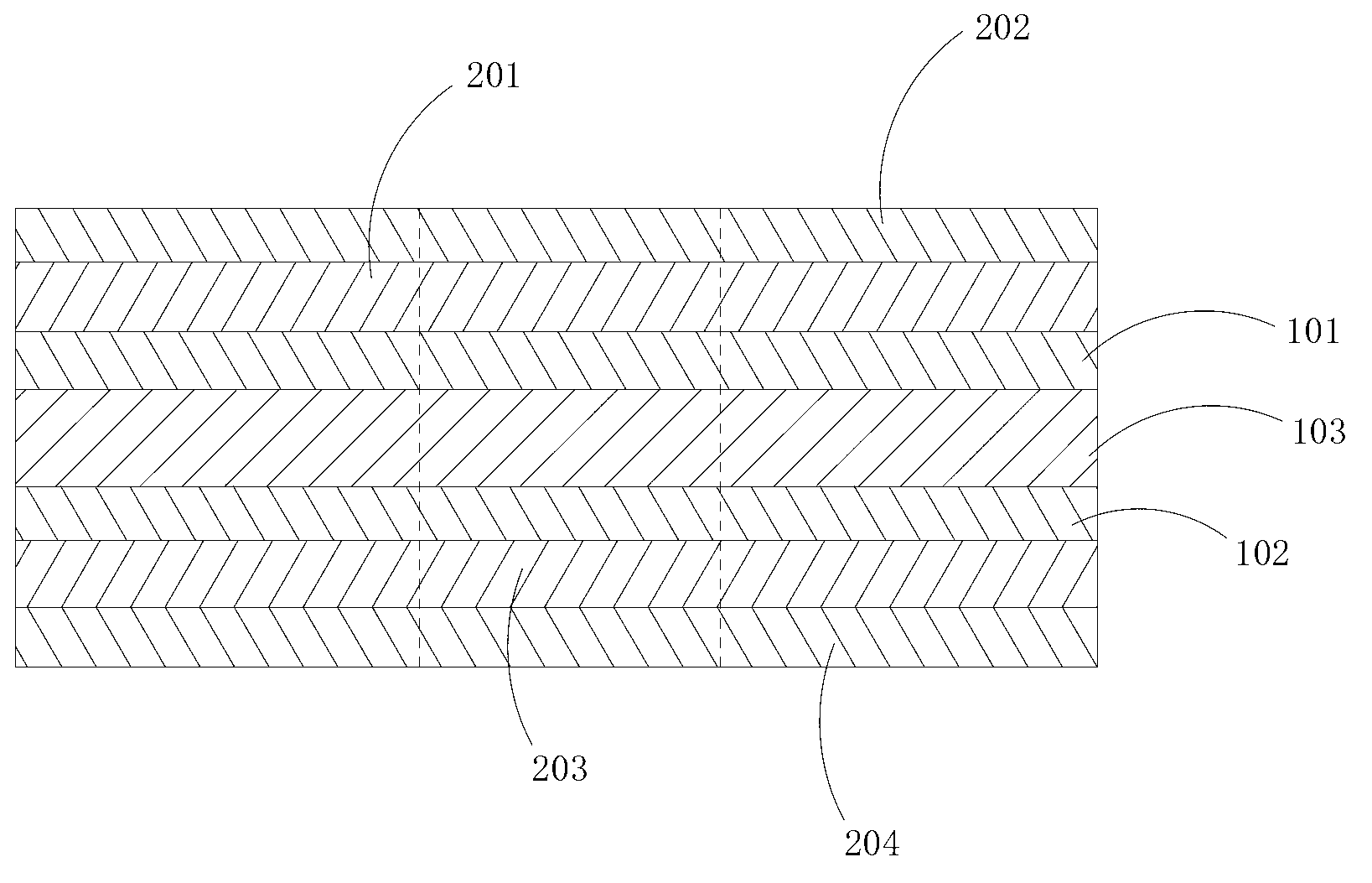

[0024] see figure 1 , providing an inner rigid circuit board. In this embodiment, the inner rigid circuit board 100 is a double-sided board and the circuit pattern has been prepared. Specifically, the inner rigid circuit board 100 includes a first circuit layer 101 , a second circuit layer 102 , and a first rigid insulating substrate 103 located between the first circuit layer 101 and the second circuit layer 102 . The inner rigid circuit board 100 is divided into a flexible area 10 and a non-flexible area 20, and the flexible area 10 is used for bending. In the fabrication of the first circuit layer 101 and the second circuit layer 102, steps such as material cutting, inner layer pattern transfer, etching and black oxidation are generally require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com