Method for stabilizing treatment on soluble manganese ions and soluble liquid selenium in electrolyzed manganese slag

A technology for stabilization treatment and electrolysis of manganese slag, applied in the fields of pollution reduction and environmental engineering, can solve the problems of polluted water and soil, polluted groundwater, etc., and achieve the effect of protecting the environment, solving the pollution environment, and having a wide range of raw material sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

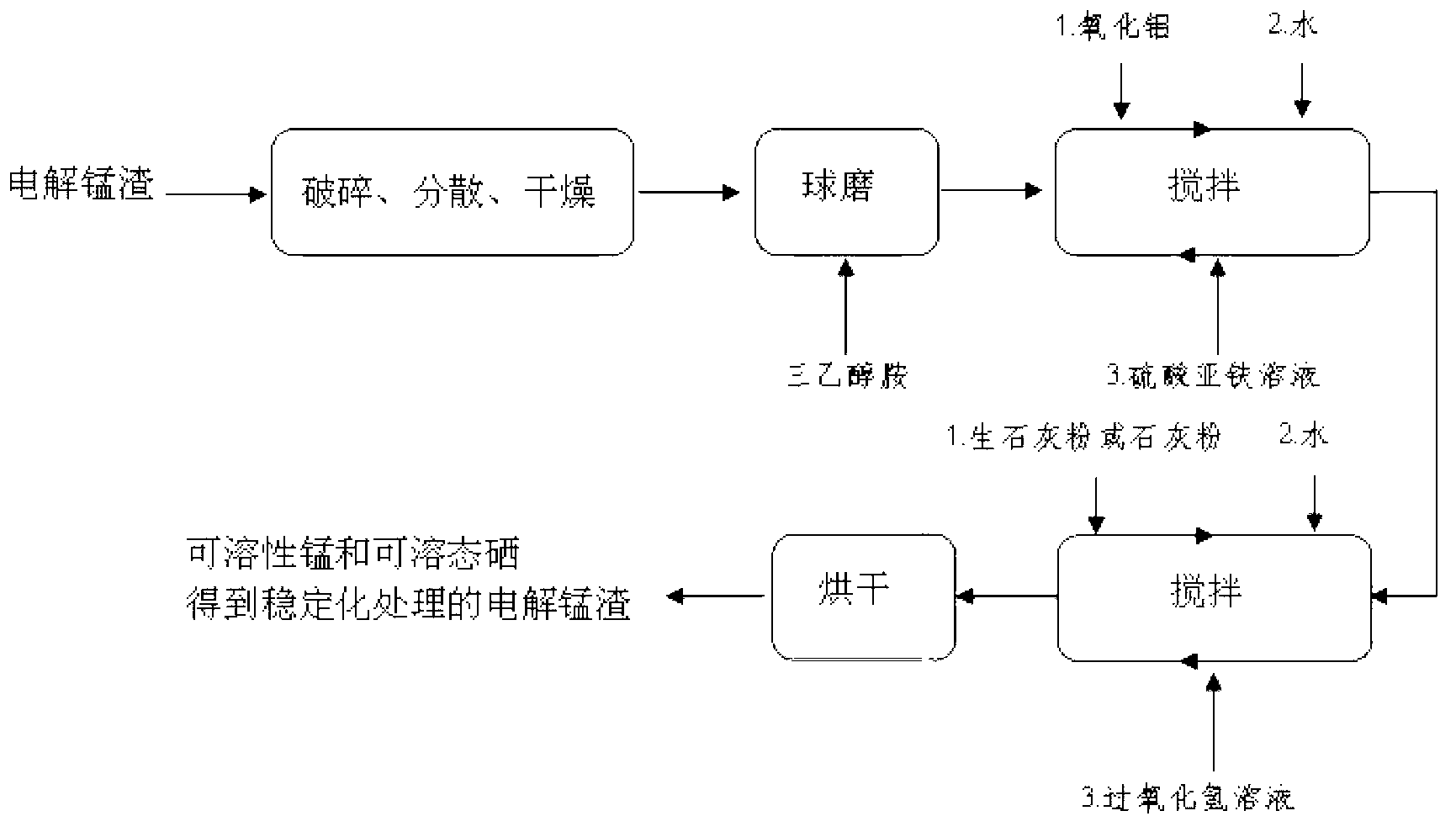

[0045] A method for stabilizing treatment of soluble manganese ions and soluble selenium in electrolytic manganese slag includes the following steps:

[0046] Step 1: Crush, disperse, and dry the newly discharged electrolytic manganese slag to obtain material I;

[0047] Step 2: Ball mill the material I, and add triethanolamine, the added amount of the triethanolamine is 0.5% of the mass of the material I, to obtain the material II;

[0048] Step 3. Add alumina to the material II, the addition amount of the alumina is 2% of the mass of the material II; after stirring evenly, slowly add clear water several times, the clear water is misty, and the addition amount is 40% of the mass of the mixture after adding clear water, stir for 3 minutes; continue to add ferrous sulfate solution, the mass fraction of the ferrous sulfate solution is 15%, the added amount and the liquid-to-solid ratio of the material II is 1:20, stir 1min, get material III;

Embodiment 2

[0053] A method for stabilizing treatment of soluble manganese ions and soluble selenium in electrolytic manganese slag includes the following steps:

[0054] Step 1: Crush, disperse, and dry the newly discharged electrolytic manganese slag to obtain material I;

[0055] Step 2: Ball mill the material I, and add triethanolamine, the added amount of the triethanolamine is 1% of the mass of the material I, to obtain the material II;

[0056] Step 3. Add alumina to the material II, the addition amount of the alumina is 2% of the mass of the material II; after stirring evenly, slowly add clear water several times, the clear water is misty, and the addition amount is 50% of the mass of the mixture after adding clear water, stir for 4 minutes; continue to add ferrous sulfate solution, the mass fraction of the ferrous sulfate solution is 20%, the added amount and the liquid-to-solid ratio of the material II is 1:25, stir 2min, get material III;

Embodiment 3

[0061] A method for stabilizing treatment of soluble manganese ions and soluble selenium in electrolytic manganese slag includes the following steps:

[0062] Step 1: Crush, disperse, and dry the newly discharged electrolytic manganese slag to obtain material I;

[0063] Step 2: Ball mill the material I, and add triethanolamine. The added amount of the triethanolamine is 0.8% of the mass of the material I to obtain the material II;

[0064] Step 3. Add alumina to the material II, the addition amount of the alumina is 2% of the mass of the material II; after stirring evenly, slowly add clear water several times, the clear water is misty, and the addition amount is 45% of the mass of the mixture after adding clear water, stir for 3 minutes; continue to add ferrous sulfate solution, the mass fraction of the ferrous sulfate solution is 18%, the added amount and the liquid-to-solid ratio of the material II is 1:22, stir 1min, get material III;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com