Tin oxide room-temperature gas-sensitive element and its preparation method

A technology of gas sensor and tin oxide, which is applied in anodic oxidation, instruments, analytical materials, etc., can solve the problems of complex process, unsuitable low-concentration toxic gas detection, and low sensitivity, so as to increase the contact area, improve sensitivity and response Time and structure are simple and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

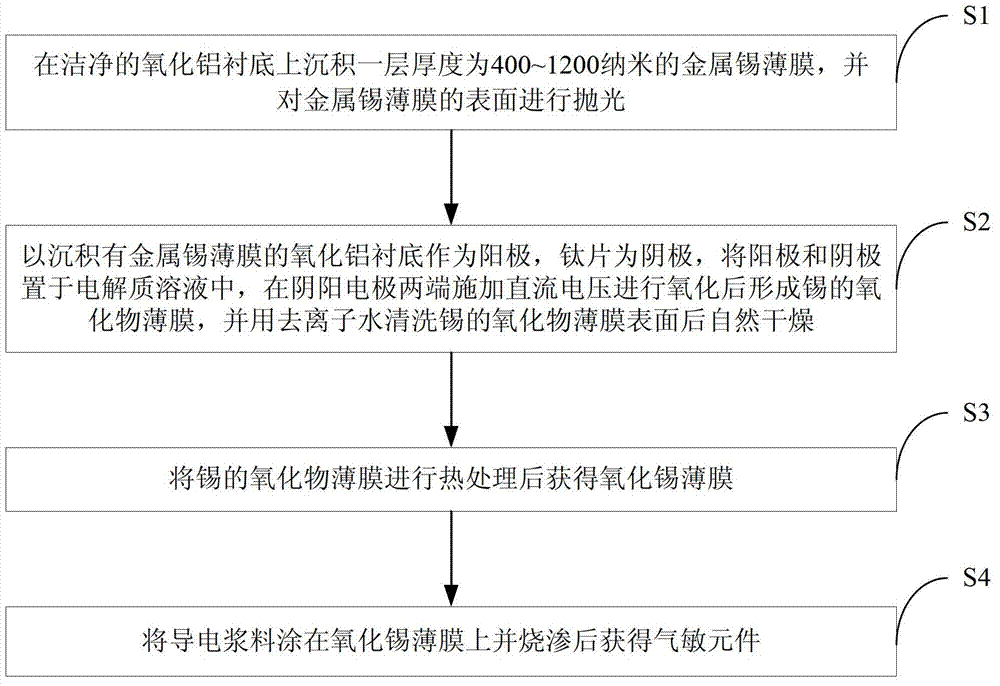

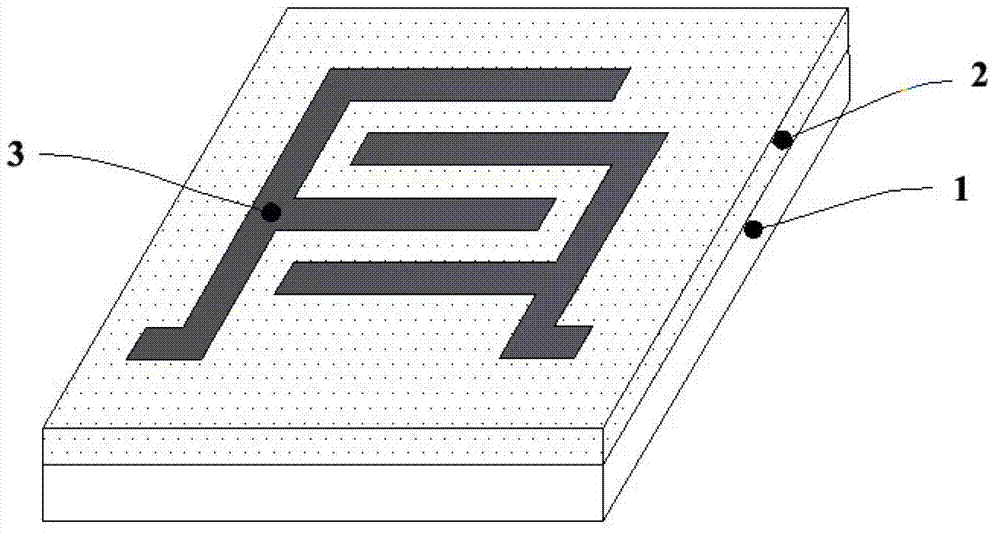

[0026] The preparation method of tin oxide room temperature gas sensor comprises the steps:

[0027] S1: Deposit a layer of metal tin film with a thickness of 400-1200 nanometers on a clean alumina substrate, and polish the surface of the metal tin film; among them, the method of magnetron sputtering can be used on a clean alumina substrate Metal tin film deposited on; SiO can be used 2 The polishing liquid polishes the surface of the film. If the film deposited by magnetron sputtering is too thin, the film will be discontinuous; if it is too thick, the film will not be fully oxidized; if the oxidation voltage is too low, the film will not be oxidized or oxidized too slowly; if it is too high, the film structure will be damaged due to excessive oxidation.

[0028] S2: The aluminum oxide substrate deposited with a metal tin film is used as the anode, and the titanium sheet is used as the cathode. The anode and the cathode are placed in the electrolyte solution, and a 5-12 volt...

Embodiment 1

[0034] (1) Deposit a film with a thickness of 400nm on a clean alumina substrate by magnetron sputtering, and use SiO 2 The polishing liquid polishes the surface of the film.

[0035] (2) The sputtered film is used as the anode, the titanium sheet is used as the cathode, the distance between the electrodes is 1.5cm, a DC voltage of 5 volts is applied, the solution is 0.1mol / L potassium hydroxide solution, and tin oxide porous can be formed after oxidation for 2 minutes Film (most of which is stannous oxide), the surface of the film was cleaned with deionized water and dried naturally.

[0036] (3) During sintering, first raise the heating rate to 180°C at a heating rate of 50°C / h and keep it warm for 1 hour to oxidize the unoxidized tin to prevent the metal tin from dissolving and destroying the film structure, and then raise the heating rate to 650°C at a heating rate of 150°C / h Keep warm for 3 hours to completely oxidize the product to tin dioxide.

[0037] (4) Use the met...

Embodiment 2

[0040](1) Deposit a metal tin film with a thickness of 1000nm on a clean alumina substrate by magnetron sputtering, and use SiO 2 The polishing liquid polishes the surface of the film.

[0041] (2) Use the above-mentioned polished film as the anode, use the titanium sheet as the cathode, the distance between the electrodes is 2 cm, the solution is 0.3 mol / L oxalic acid solution, apply a DC voltage of 8 volts, and form a tin oxide porous film after oxidation for 1 min. Wash with deionized water and dry naturally.

[0042] (3) During sintering, first heat the above obtained film at 180°C for 1 hour to oxidize the non-oxidized tin to prevent the dissolution of metal tin from destroying the film structure, and then raise it to 500°C for 3 hours to completely oxidize the product into tin dioxide .

[0043] (4) Use the screen printing method to coat the silver paste on the tin oxide film, and get the gas sensor after firing.

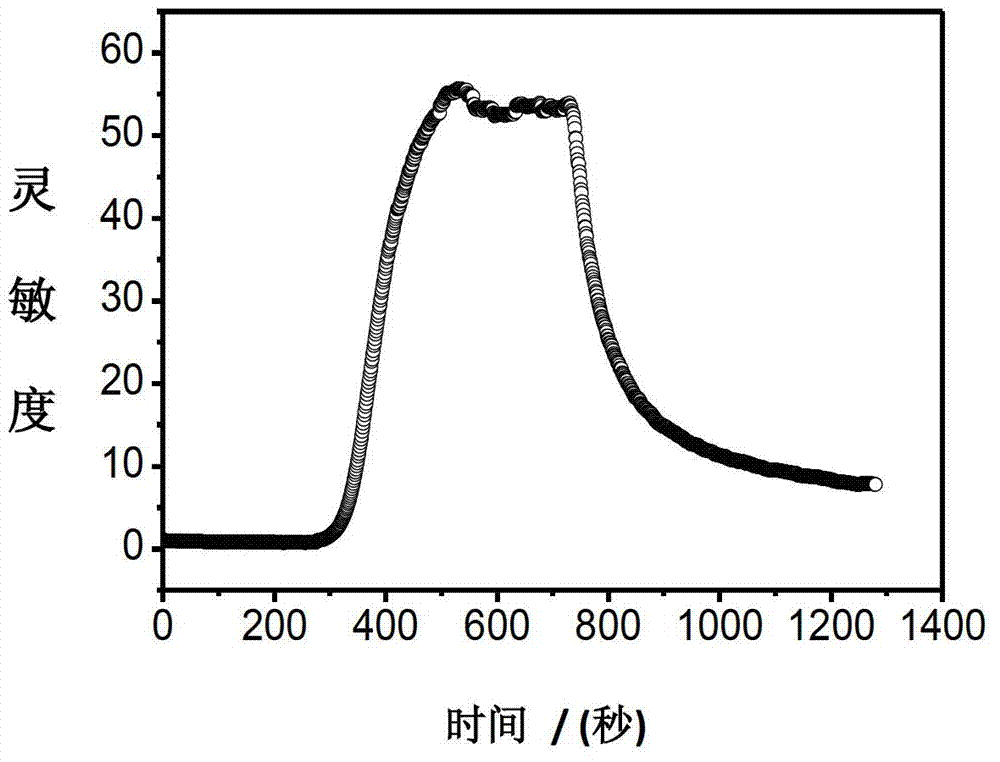

[0044] The gas sensor prepared by the method provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com