Anti-drag wear-resistant paint for pipelines and preparation method thereof

A technology of wear-resistant coatings and pipelines, which is applied in the direction of pipeline damage/abrasion prevention, pipeline protection, epoxy resin coatings, etc. It can solve problems such as unstable quality, difficult construction, complex components of drag-reducing and wear-resistant coatings, and achieve excellent performance Mechanical properties, convenient construction, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: This drag-reducing and wear-resistant coating for pipelines includes A component and B component, wherein A component includes epoxy resin with a mass percentage of 68.8%, butyl acetate with a mass percentage of 30%, and a layer with a mass percentage of 1% Shape-spherical nano filler, 0.1% by mass percentage of polyethylacrylate leveling agent and 0.1% by mass percentage of polysiloxane defoamer, B component is polyamide-6 resin; A component and B component according to The mass ratio is 3:1 for mixed use.

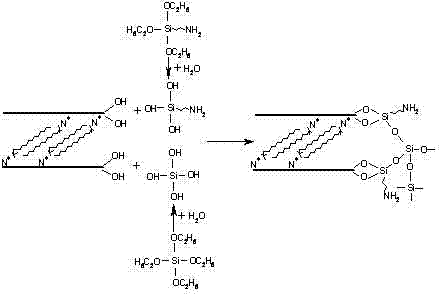

[0028]Wherein the lamellar-spherical nanofiller is prepared as follows: adding organic clay, ethanol with a mass percentage concentration of 98%, distilled water and ammoniacal liquor with a mass percentage concentration of 28% in the reactor, wherein the ratio of ethanol to distilled water is 90:10, The amount of ammonia water added is 5% of the total mass of ethanol and distilled water, and the amount of organoclay added is 60% of the total mass of eth...

Embodiment 2

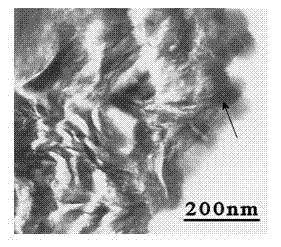

[0034] Embodiment 2: This drag-reducing wear-resisting paint for pipeline comprises A component and B component, and wherein A component comprises the epoxy resin of 70% by mass percentage, the butyl propionate of 20% by mass percentage, the butyl propionate of 9.4% by mass % Layered-spherical nanofillers (the mass percentage of organic clay and silicon dioxide is 2:1, and its microscopic appearance is as attached figure 1 ,from figure 1 can clearly see the microstructure of layered clay and spherical silica), 0.3% by mass of polybutyl acrylate leveling agent and 0.3% by mass of polyether modified polysiloxane defoamer, B The component is polyamide-66 resin; component A and component B are mixed in a mass ratio of 4:1.

[0035] Wherein the lamellar-spherical nanofiller is prepared as follows: adding organic clay, ethanol with a mass percentage concentration of 98%, distilled water and ammoniacal liquor with a mass percentage concentration of 28% in the reactor, wherein the ...

Embodiment 3

[0040] Embodiment 3: This drag-reducing wear-resisting paint for pipeline comprises A component and B component, and wherein A component comprises the copolymer of epoxy resin and polyurethane of mass percentage 69.6% (the mass ratio of epoxy resin and polyurethane is 90 : 10), 25% by mass of butyl acetate, 5% by mass of layered-spherical nanofillers (the mass percentage of organoclay and silica is 4:1), 0.2% by mass of epoxy-based polyacrylate Leveling agent and polyester modified polysiloxane defoamer with a mass percentage of 0.2%, B component is polyamide-6 resin; A component and B component are mixed and used at a mass ratio of 5:1.

[0041] Wherein the lamellar-spherical nanofiller is prepared as follows: adding organic clay, ethanol with a mass percentage concentration of 98%, distilled water and ammoniacal liquor with a mass percentage concentration of 28% in the reactor, wherein the ratio of ethanol to distilled water is 70:30, The amount of ammonia water added is 8% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com