Method for producing nano-silver composite antibacterial agent through spray drying

A composite antibacterial agent and nano-silver technology, applied in the directions of biocides, fungicides, biocides, etc., can solve the problems of difficult to control the hydrophilicity and hydrophobicity of the particle surface, uneven size of nano-silver composite particles, and difficult to adjust the size of silver particle size. , to achieve excellent disinfection and antibacterial performance, high-efficiency broad-spectrum disinfection and antibacterial performance, and the effect of eliminating instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

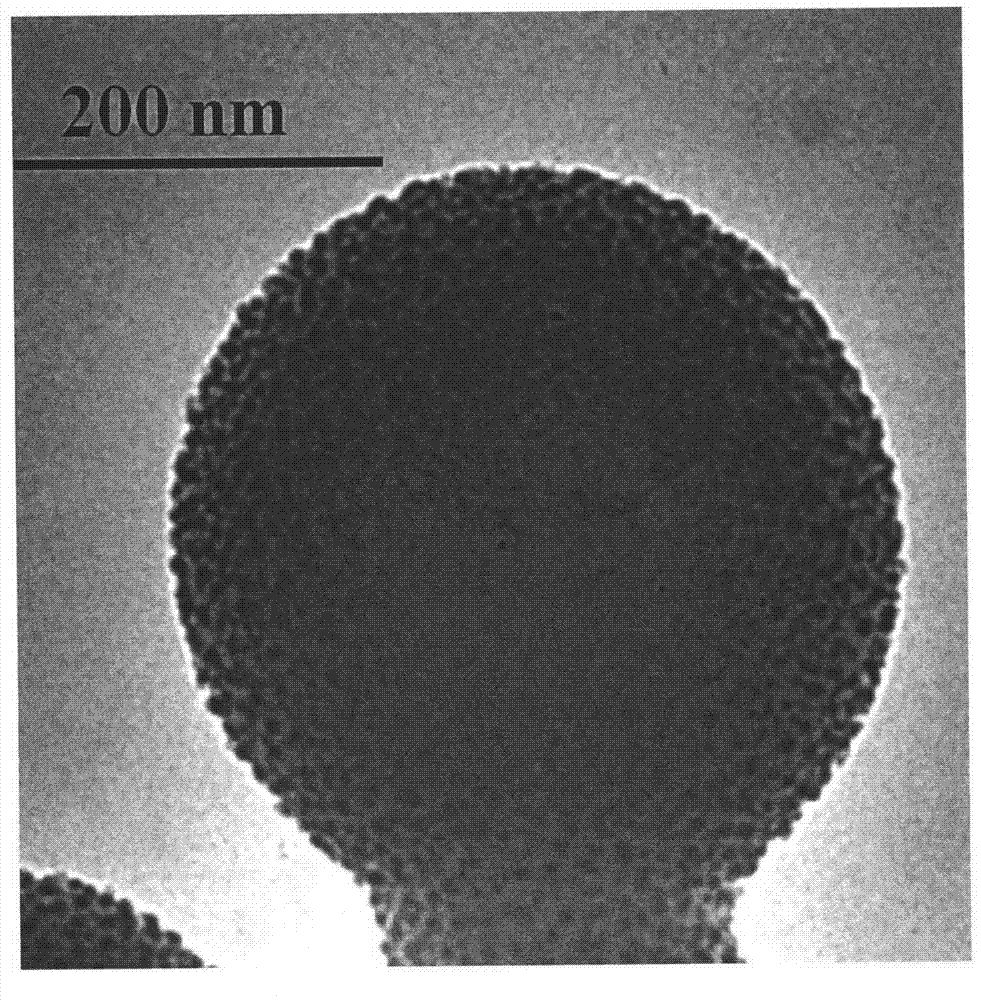

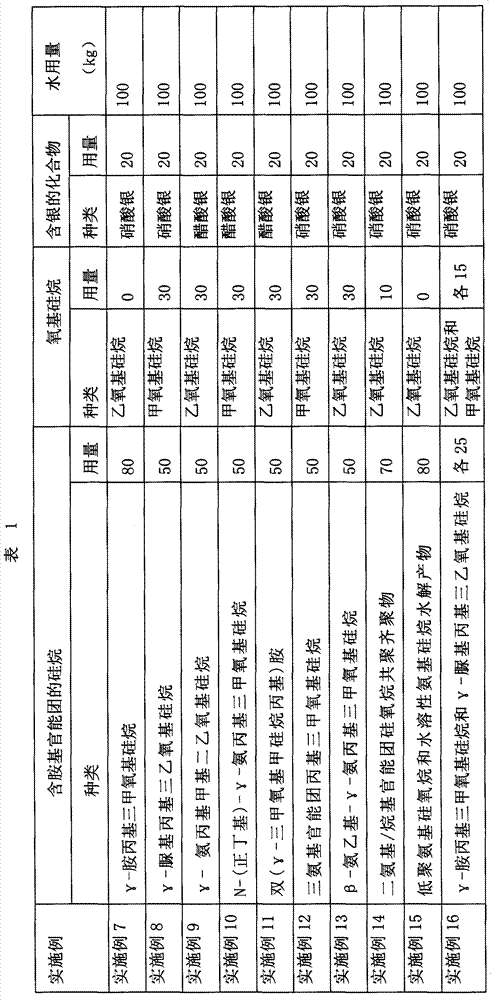

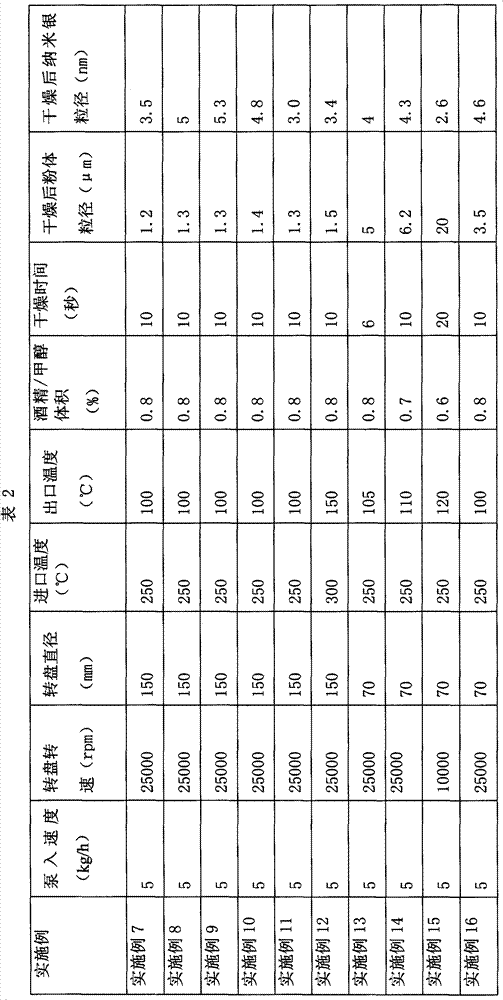

[0023] Mix 50 kg of γ-aminopropyltriethoxysilane with 30 kg of ethoxysilane, 100 kg of water, and 20 kg of silver nitrate; pump it into a high-speed rotating spray disc with a diameter of 150 mm at a constant speed of 5 kg per hour. The rotation speed of the rotating turntable is 25000rpm, and the tiny droplets atomized by high-speed centrifugal are dried by 400 cubic meters per hour and 250℃ hot air cyclone. After cyclone separation, they are collected and packaged. After drying, the average particle size of the particles is 1μm, and the alcohol content in the air is 0.8% (volume) , The drying time is 10 seconds, and the average particle size of nano-silver after drying is 3.2 nanometers. TEM image of spray-dried silver / silica particles synthesized as figure 1 shown.

Embodiment 2

[0025] Mix 50 kg of γ-aminopropyltriethoxysilane with 30 kg of ethoxysilane, 100 kg of water, and 1 kg of silver nitrate; pump it into a high-speed rotating spray disc with a diameter of 150 mm at a constant speed of 5 kg per hour. The rotation speed of the rotating turntable is 10000rpm, and the tiny droplets atomized by high-speed centrifugal are dried by 400 cubic meters per hour hot air at 250℃, and collected and packaged after cyclone separation. After drying, the particle size is 2 μm. The alcohol content in the air is 0.8% (volume). Drying time 10 seconds. After drying, the average particle size of nano-silver is 1 nanometer.

Embodiment 3

[0027]Mix 50 kg of γ-aminopropyltriethoxysilane with 30 kg of ethoxysilane, 100 kg of water, and 40 kg of silver nitrate; pump it into a high-speed rotating spray disc with a diameter of 150 mm at a constant speed of 20 kg per hour, and The rotation speed of the rotating turntable is 10000rpm, and the tiny droplets atomized by high-speed centrifugal are dried by 400 cubic meters per hour of hot air at 250℃, and collected and packaged after cyclone separation. After drying, the particle size is 6 μm. The alcohol content in the air is 3% (volume). Drying time 10 seconds. After drying, the average particle diameter of nano-silver is 3.8 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com