Compound-function wallpaper and preparation method thereof

A composite function, wallpaper technology, used in covering/lining, architecture, building structure, etc., can solve the problems of flame retardant wallpaper moisture regain, affecting performance, porous material adhesive blocking and other problems, to achieve the effect of low moisture regain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

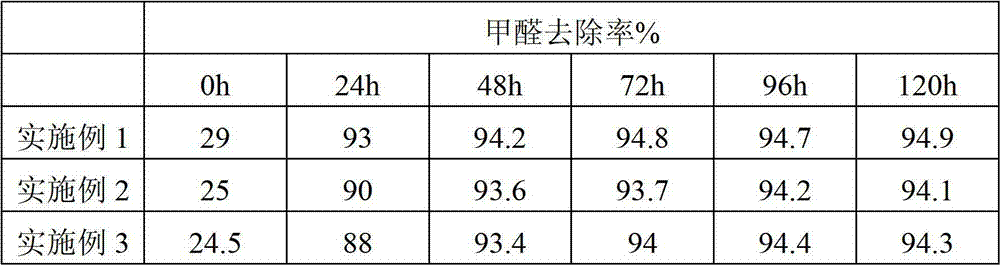

Examples

Embodiment 1

[0043] Embodiment 1, prepare composite functional wallpaper

[0044] (1) Soak the non-woven fabric in the flame retardant finishing solution for 5 minutes, take it out and dry it at 100°C for 3 minutes to obtain the matrix layer; wherein, the composition of the flame retardant finishing solution is: 20 parts of diguanidine hydrogen phosphate , 3 parts of penetrating agent Lutensol XP-50 and 77 parts of water, all are parts by weight.

[0045](2) Add 20 parts by weight of 50% ammonium polyphosphate aqueous solution, 15 parts by weight of formaldehyde-removing ultrafine powder, and 3 parts by weight of polyethylene glycol to 61 parts by weight of formaldehyde-free polyurethane, at 1800r / min Stir evenly under the same conditions, then add 1 part by weight of water-based color paste for coloring, adjust to a suitable viscosity with 1 part by weight of hydroxyethyl cellulose, and scrape it on the substrate layer with a flat plate to form an adhesive layer. The gram weight is 30g / m...

Embodiment 2

[0048] Embodiment 2, prepare composite functional wallpaper

[0049] (1) Soak the non-woven fabric in the flame retardant finishing solution for 7 minutes, take it out and dry it at 100°C for 5 minutes to obtain the matrix layer; wherein, the composition of the flame retardant finishing solution is: organophosphorus flame retardant (diguanidine hydrogen phosphate) 25 parts, penetrant JFC 2 parts and water 73 parts, all are parts by weight.

[0050] (2) Add 25 parts by weight (35% aqueous guanylurea phosphoric acid solution), 12 parts by weight of formaldehyde-removing ultrafine powder and 4 parts by weight of polyethylene glycol to 57 parts by weight of formaldehyde-free polyacrylate , Stir evenly under the condition of 2000r / min, then add 1 part by weight of water-based color paste for coloring, adjust to a suitable viscosity with 1 part by weight of hydroxyethyl cellulose, and apply it on the substrate layer with a flat plate to form an adhesive layer, its grammage is 20g / m...

Embodiment 3

[0053] Embodiment 3, prepare composite functional wallpaper

[0054] (1) Soak the non-woven fabric in the flame retardant finishing solution for 10 minutes, take it out and dry it at 105°C for 5 minutes to obtain the matrix layer; wherein, the composition of the flame retardant finishing solution is: organophosphorus flame retardant (Diguanidine hydrogen phosphate) 30 parts, penetrant XP-501 parts and water 69 parts, all are parts by weight.

[0055] (2) 30 parts by weight of bromine-antimony-based flame retardant powder (a mixture of antimony trioxide and decabromodiphenyl ether in a weight ratio of 1:4), 10 parts by weight of formaldehyde-removing ultrafine powder and 4 parts by weight Add polyethylene glycol to 52.5 parts by weight of formaldehyde-free polyurethane, stir evenly under the condition of 2000r / min, then add 2 parts by weight of water-based color paste for color adjustment, adjust to 0.5 parts by weight of hydroxyethyl cellulose Appropriate viscosity, scrape on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com