A novel composite nanofibrous membrane and its preparation method and application

A composite nanofiber, a new type of technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as limited use and single function, and achieve the effect of clear principle, short process flow, and prevention of vitamin loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

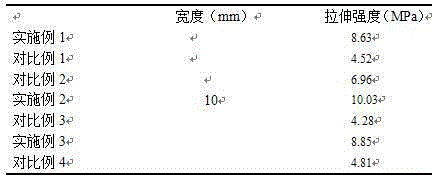

Embodiment 1

[0039] (1) Dissolve the weighed polyvinyl alcohol with an average degree of polymerization of 500-3000 and a degree of alcoholysis of 65-99% in a mixed solution of acetone and DMAc, wherein the volume ratio of acetone and DMAc is 5:3 , configured into a polyvinyl alcohol spinning solution with a mass fraction of 15%, and stirred to dissolve it;

[0040] (2) Add the weighed vegetable tannin into the dissolved spinning solution, and the vegetable tannin accounts for 1% of the total mass of the vegetable tannin and the organic solvent;

[0041] (3) Treat the mixed spinning solution on an ultrasonic processor for 1 min;

[0042] (4) Inject the processed mixed spinning solution into the liquid storage tube of the electrospinning device, fix it on the micro-syringe pump, the inner diameter of the capillary is 0.5mm, and the electrospinning process conditions are: voltage 18kV, flow rate 0.5ml / h; The composite nanofiber membrane was received by the copper foil plate receiving metho...

Embodiment 2

[0045] (1) Dissolve the weighed polylactic acid in the methylene chloride solution to prepare a spinning solution with a mass fraction of 5%, and stir the spinning solution on a magnetic stirrer for 10 hours;

[0046] (2) Add polyphenolic substances to the above spinning solution, stir evenly to obtain a mixed spinning solution accounting for 5% of the total mass of the polyphenolic substances and the organic solvent, and the polyphenolic substances are Vegetable tannins and grape polyphenols mixed at a ratio of 1:1;

[0047] (3) Put the mixed spinning solution on the ultrasonic processor for 60 minutes;

[0048] (4) Inject the processed spinning liquid into the liquid storage tube of the electrospinning device, and fix it on the micro-syringe pump. The inner diameter of the capillary is 0.6mm. The electrospinning process conditions are: voltage 6kV, flow rate 0.05ml / h; Accept the composite nanofiber membrane with the aluminum foil roller receiving method, and the receiving ...

Embodiment 3

[0051] (1) Dissolve the weighed regenerated silk fibroin in 88% formic acid solution to prepare a spinning solution with a mass fraction of 20%;

[0052] (2) Weighed plant tannins and grape polyphenols are added to the dissolved spinning solution at a mass ratio of 1:0.5, with a mass fraction of 10%. The mass fraction is the proportion of polyphenols to polyphenols and the fraction of the total mass of the organic solvent;

[0053] (3) Put the mixed spinning solution on the ultrasonic processor for 300 minutes;

[0054] (4) Pour the processed spinning liquid into the liquid storage tube of the electrospinning device, and fix it on the micro-syringe pump. The inner diameter of the capillary is 0.7mm. The electrospinning process conditions are: voltage 30kV, flow rate 0.8ml / h; The composite nanofiber membrane is received by the aluminum foil plate receiving method, and the receiving distance is 20cm.

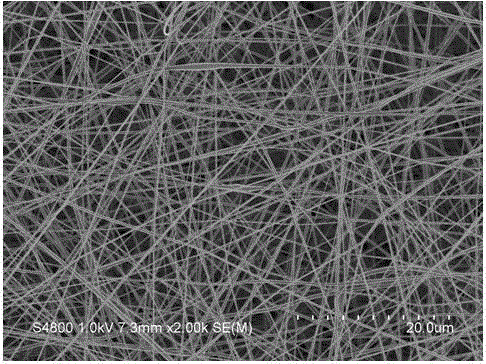

[0055] The diameter size and distribution of the prepared composite nanofi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com