Cutter

A cutting and cutting part technology, applied in the field of cutting devices, can solve problems such as single straight line cutting function, and achieve the effect of increasing functions and improving single functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

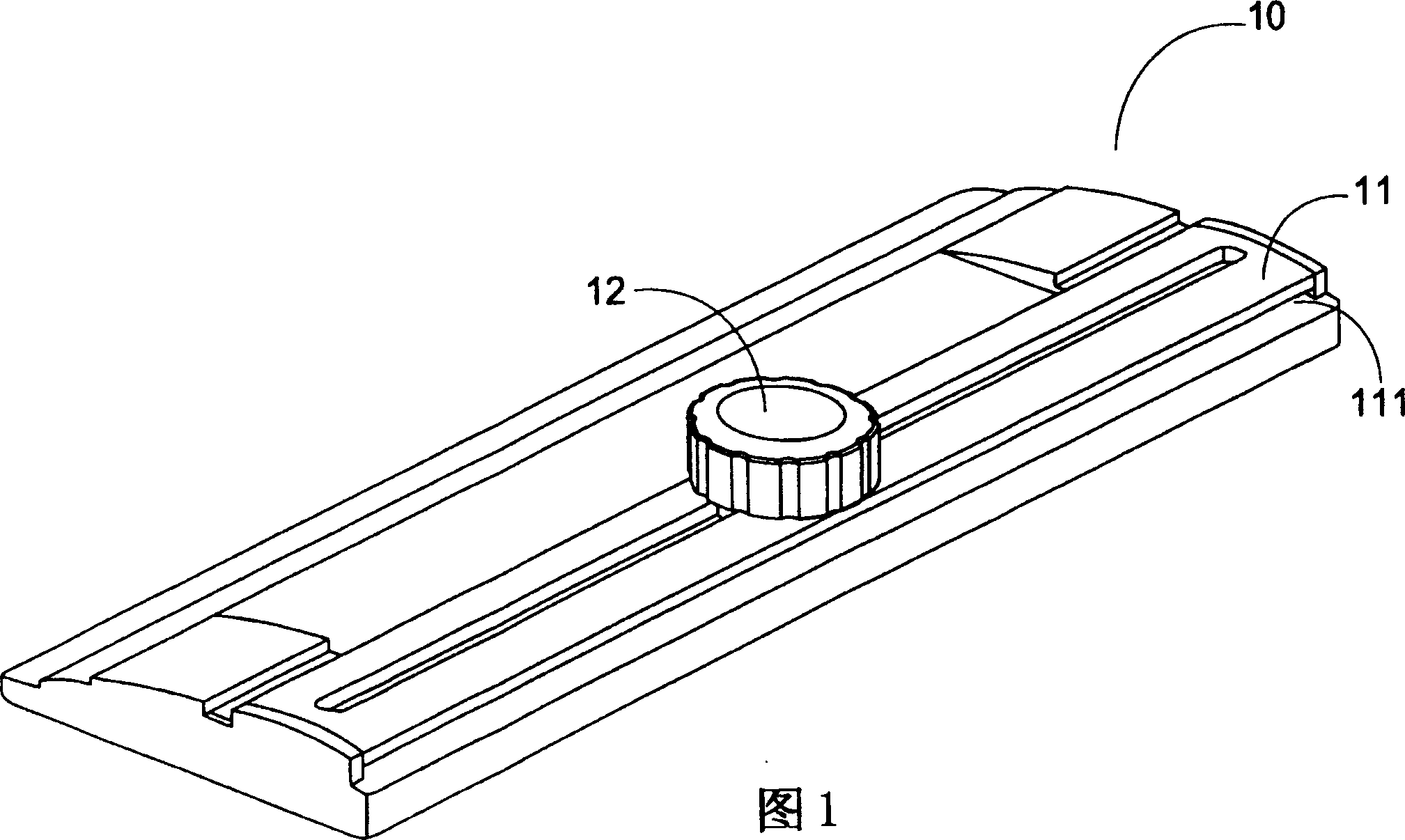

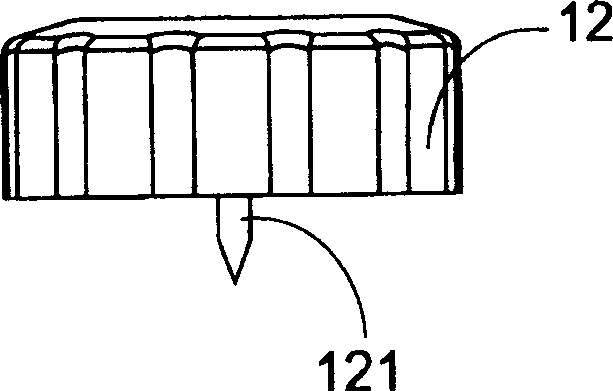

[0025] Such as image 3 As shown, the cutting device 3 of the present invention is mainly used for cutting a flat material (not shown), and the cutting device 3 at least includes a slide rail 31 , a cross bar 32 and an object 33 . Wherein the bottom of the slide rail 31 has a space 311 in order to provide the placement of the plane material, and the crossbar 32 has a cutting portion 321 for cutting the plane material, in addition, the object 33 passes through the slide rail 31 and is connected to the plane material. The crossbar 32 is connected. When cutting, provide a pressure to the object 33 and make the slide rail 31 suppress the plane material, and the object 33 moves along the slide rail 31, driving the cutting portion 321 of the cross bar 32 to perform straight cutting . In addition, by moving the object 33 along the slide rail 31 in a state where the cutting portion 321 is not in contact with the planar material, its working position can be changed, and on different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com