Method for preparing porous hollow nano-alumina fiber by static spinning

A nano-alumina and nano-fiber technology, applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of complex electrospinning equipment and cumbersome process, and achieve good environmental friendliness, high specific surface area, and equipment requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

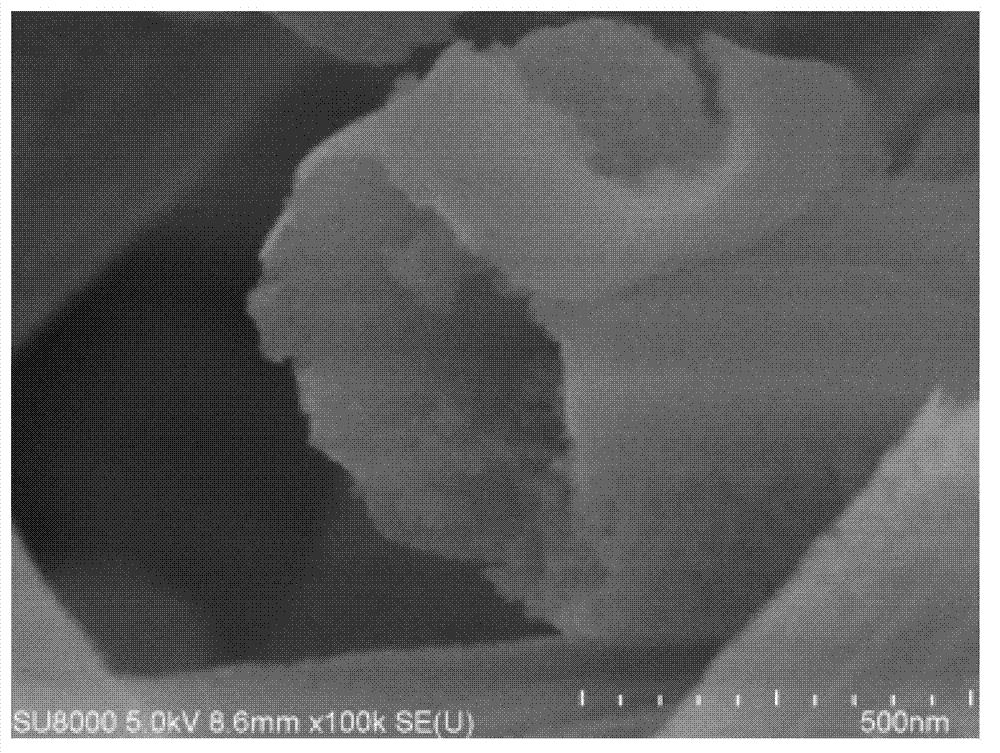

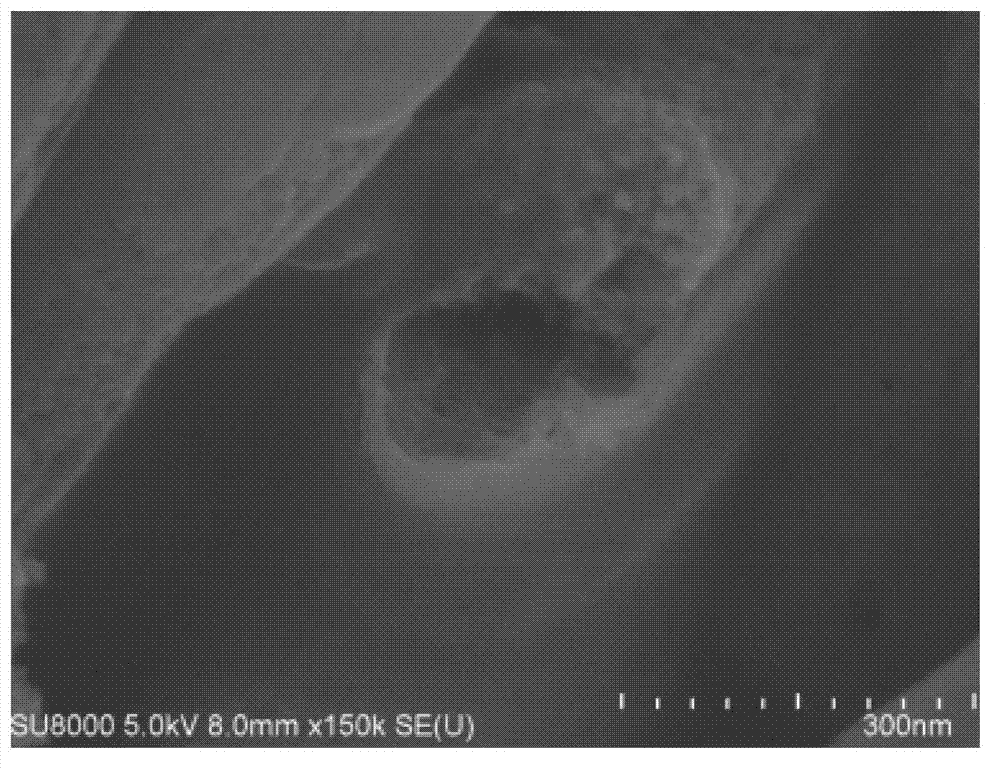

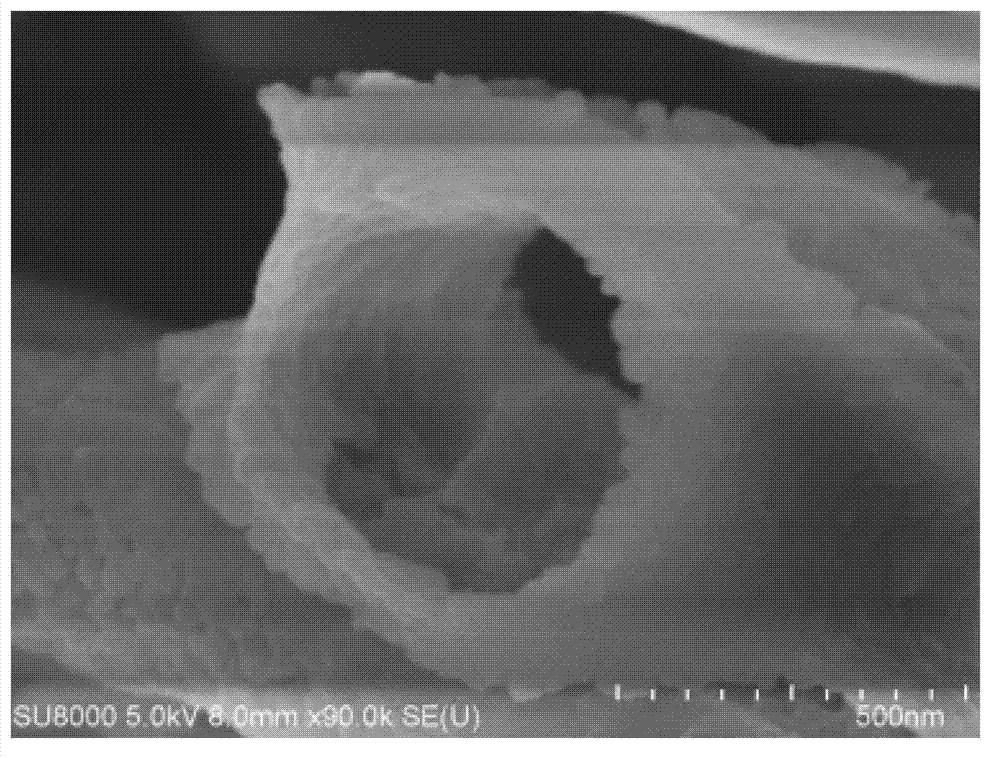

[0029] Add 0.1~1gAl(NO 3 ) 3 9H 2 O was dissolved in 9g of DMF, and after stirring and dissolving, 1g of PAN (Mw=80000) was added to prepare a uniform and transparent light yellow spinning solution under heating. Under the conditions of voltage of 10KV, injection speed of 0.5mL / min, and receiving distance of 5cm, nanofibers were obtained by electrospinning, and hollow nano-alumina fibers were obtained by sintering at 500, 1000, and 1300°C for 1-2h respectively (see figure 1 , figure 2 and image 3 ).

Embodiment 2

[0031] Dissolve 0.1~1g of aluminum acetate in 9g of DMF, stir and dissolve, add 1g of PAN (Mw=80000), and prepare a uniform and transparent light yellow spinning solution under heating. Under the conditions of voltage 30KV, injection speed 2mL / min, and receiving distance 10cm, nanofibers were obtained by electrospinning, and hollow nano-alumina fibers were obtained by sintering at 500, 1000, and 1300°C for 1-2 hours respectively.

Embodiment 3

[0033] Dissolve 0.1~1g of aluminum acetylacetonate in 9g of ethanol, stir and dissolve, add 1g of PVP (Mw=1300000), and prepare a uniform and transparent light yellow spinning solution under heating. Under the conditions of voltage of 25KV, injection speed of 2.5mL / min, and receiving distance of 15cm, nanofibers were obtained by electrospinning, and hollow nano-alumina fibers were obtained by sintering at 500, 1000, and 1300°C for 1-2h respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com