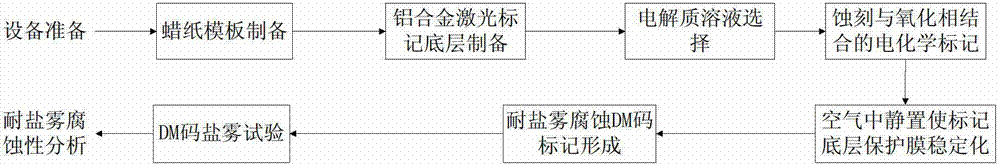

Laser marking method for increasing salt spray corrosion resistance of two-dimension codes on surface of aluminum alloy

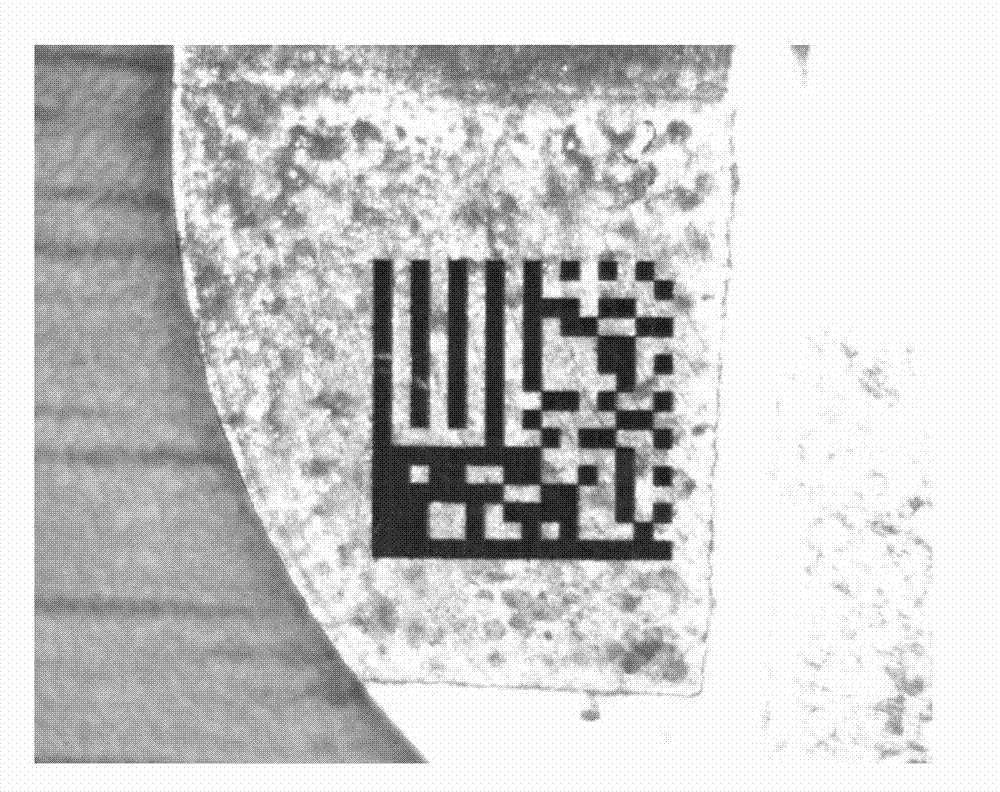

A technology of aluminum alloy surface and laser marking, applied in the field of laser marking, can solve the problems of DM code edge or module blurring, unclear, data loss, etc., achieve small contrast drop, avoid pollution, and improve salt spray corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

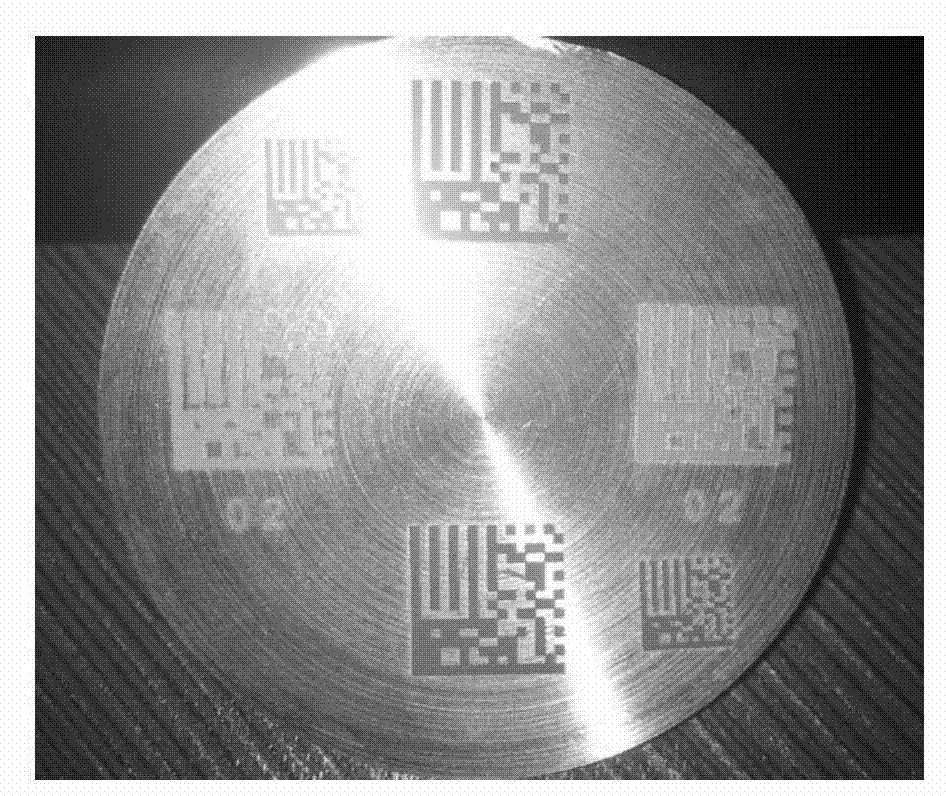

[0060] In this embodiment, the aluminum alloy sheet material with the grade of 2A12 is selected as the aluminum alloy test piece to be marked, and its specification is Ф50*5mm.

[0061] The steps of this embodiment are:

[0062] Step 1: Determine the laser marking process parameters:

[0063] Step 1.1: Grinding the marked surface of the aluminum alloy test piece, so that the surface roughness of the marked surface meets the marking requirements of the laser marking machine. The surface roughness of the marked face in this embodiment is about 3.2 μm;

[0064] Step 1.2: Use Han's YLP-D10 fiber laser marking machine to mark the DM code on the marking surface, the code word is "30Q324343430794<OQQ", the barcode size is 8*8mm, and follow the NASA standard AIM-DPM-1-2006 , Use "Microscan" barcode calibrator to check the quality of the marked DM code;

[0065] Step 1.3: Adjust the laser marking process parameters of the laser marking machine, repeat step 1.2 until the overall quali...

Embodiment 2

[0083] In this embodiment, the aluminum alloy sheet material with the grade of 2A12 is selected as the aluminum alloy test piece to be marked, and its specification is Ф50*5mm.

[0084] The steps of this embodiment are:

[0085] Step 1: Determine the laser marking process parameters:

[0086] Step 1.1: Grinding the marked surface of the aluminum alloy test piece, so that the surface roughness of the marked surface meets the marking requirements of the laser marking machine. The surface roughness of the marked face in this embodiment is about 3.2 μm;

[0087] Step 1.2: Use Han's YLP-D10 fiber laser marking machine to mark the DM code on the marking surface, the code word is "30Q324343430794<OQQ", the barcode size is 8*8mm, and follow the NASA standard AIM-DPM-1-2006 , Use "Microscan" barcode calibrator to check the quality of the marked DM code;

[0088] Step 1.3: Adjust the laser marking process parameters of the laser marking machine, repeat step 1.2 until the overall quali...

Embodiment 3

[0105] In this embodiment, the aluminum alloy sheet material with the grade of 2A12 is selected as the aluminum alloy test piece to be marked, and its specification is Ф50*5mm.

[0106] The steps of this embodiment are:

[0107] Step 1: Determine the laser marking process parameters:

[0108] Step 1.1: Grinding the marked surface of the aluminum alloy test piece, so that the surface roughness of the marked surface meets the marking requirements of the laser marking machine. The surface roughness of the marked face in this embodiment is about 3.2 μm;

[0109] Step 1.2: Use Han's YLP-D10 fiber laser marking machine to mark the DM code on the marking surface, the code word is "30Q324343430794<OQQ", the barcode size is 8*8mm, and follow the NASA standard AIM-DPM-1-2006 , Use "Microscan" barcode calibrator to check the quality of the marked DM code;

[0110] Step 1.3: Adjust the laser marking process parameters of the laser marking machine, repeat step 1.2 until the overall quali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com