Mercapto-beta-cyclodextrin modified silver nano-rode array, its preparation method and its use

A technology of silver nanoarray and silver nanorod, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve the problems of inability to produce environmental toxic pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The concrete steps of preparation are:

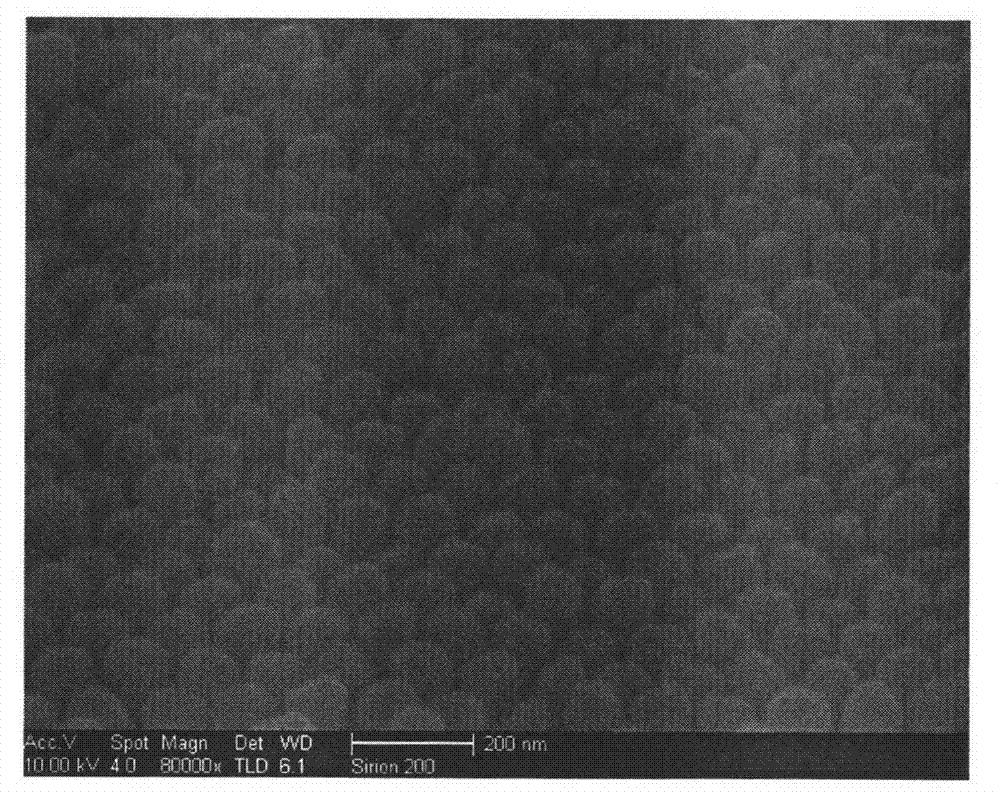

[0035] In step 1, a through-hole alumina template with a hole diameter of 60 nm is firstly obtained by secondary anodizing on the aluminum sheet. Then use the ion sputtering method to sputter a metal conductive film on one side of the through-hole aluminum oxide template; One or more than two kinds of superposition), wherein the thickness of the silver film is 50nm, and the thickness of the copper film is 20μm, and an aluminum oxide template with a metal conductive film on one side is obtained.

[0036] Step 2, first place the aluminum oxide template with a metal conductive film on one side in a silver electrolyte at a temperature of 10°C, use it as a working electrode, and deposit it at a deposition voltage of 0.2V, a frequency of 0.8KHz, and a waveform of square wave. Duty ratio is 48% pulse voltage under electrodeposition 5min, obtains the aluminum oxide template that silver nanorod is placed in the hole, one side is covered ...

Embodiment 2

[0038] The concrete steps of preparation are:

[0039] In step 1, a through-hole alumina template with a pore diameter of 68 nm is obtained by using a secondary anodic oxidation method on the aluminum sheet. Then use the ion sputtering method to sputter a metal conductive film on one side of the through-hole aluminum oxide template; One or two or more of them are superimposed), wherein the thickness of the silver film is 90nm, and the thickness of the copper film is 28μm, and an aluminum oxide template with a metal conductive film on one side is obtained.

[0040] Step 2, first place the aluminum oxide template with a metal conductive film on one side in a silver electrolyte at a temperature of 12°C, use it as a working electrode, and deposit it at a deposition voltage of 0.35V, a frequency of 0.9KHz, and a square wave waveform. Duty ratio is 49% pulse voltage under electrodeposition 4min, obtains the aluminum oxide template that silver nanorod is placed in the hole, one side...

Embodiment 3

[0042] The concrete steps of preparation are:

[0043]In step 1, a through-hole alumina template with a pore diameter of 75 nm is obtained by using a secondary anodic oxidation method on the aluminum sheet. Then use the ion sputtering method to sputter a metal conductive film on one side of the through-hole aluminum oxide template; One or two or more of them are superimposed), wherein the thickness of the silver film is 125nm, and the thickness of the copper film is 35μm, and an aluminum oxide template with a metal conductive film on one side is obtained.

[0044] Step 2, first place the aluminum oxide template with a metal conductive film on one side in a silver electrolyte at a temperature of 13°C, use it as a working electrode, and deposit it at a deposition voltage of 0.5V, a frequency of 1KHz, and a square wave waveform. The empty ratio is 50% pulse voltage under electrodeposition 3min, obtains the aluminum oxide template that has silver nanorod in the hole, one side is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com