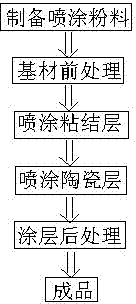

Method for preparing novel gradient thermal barrier coating

A thermal barrier coating and gradient technology, applied in the chemical field, can solve the problems of complex process links, high operation requirements and poor practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 The specific implementation steps of the preparation method of the gradient thermal barrier coating mentioned in the present invention are as follows: a) Prepare the spray powder, which includes the bonding layer powder and the ceramic layer powder; wherein, the bonding layer The powder is composed of MCrAlY alloy and an oxide that can form an oxide film. The two components need to be prepared separately; the main components of the MCrAlY alloy are: Co, Cr, Al, S and Ni. The particle size of the MCrAlY alloy after grinding is 250 mesh ; The oxide that can form an oxide film is selected from alumina, and the particle size of alumina after grinding is controlled at 350 mesh; the ceramic layer powder is made of yttria-stabilized zirconia ceramics, and the particle size after grinding is 550 mesh; Treatment, substrate pretreatment includes sandblasting, ultrasonic cleaning, deionized water cleaning and drying treatment; sandblasting uses 150-mesh glass pellets, the...

Embodiment 2

[0019] Example 2 The specific implementation steps of the preparation method of the gradient thermal barrier coating mentioned in the present invention are as follows: a) Prepare the spray powder, which includes the bonding layer powder and the ceramic layer powder; wherein, the bonding layer The powder is composed of MCrAlY alloy and an oxide that can form an oxide film. The two components need to be prepared separately; the main components of the MCrAlY alloy are: Co, Cr, Al, S and Ni. The particle size of the MCrAlY alloy after grinding is 250 mesh ; The oxide that can form an oxide film is selected from magnesium oxide, and the particle size of magnesium oxide after grinding is controlled at 400 mesh; the ceramic layer powder is calcium oxide stabilized zirconia ceramic material, and the particle size after grinding is 600 mesh; b) the base material Pre-treatment, substrate pre-treatment includes sand blasting, ultrasonic cleaning, deionized water cleaning and drying; sand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com