Method for preparing novel gradient thermal barrier coating

A thermal barrier coating and gradient technology, which is applied in the preparation of thermal barrier coatings and the preparation of new gradient thermal barrier coatings, can solve the problems of high operation requirements, high implementation costs, complex process links, etc., and achieve compact process arrangement , Moderate cost and reasonable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

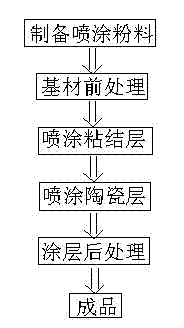

[0018] The specific implementation steps of the preparation method of the novel gradient thermal barrier coating mentioned in the present invention are as follows:

[0019] a) Preparation of spray powder, which includes adhesive layer powder and ceramic layer powder; wherein, the adhesive layer powder is composed of MCrAlY alloy and oxide that can form an oxide film, and the two components need to be prepared separately The main components of MCrAlY alloy are: Co, Cr, Al, S and Ni, the particle size of MCrAlY alloy after grinding is 250 mesh; the oxide that can form an oxide film is selected from alumina, and the particle size of aluminum oxide after grinding is controlled at 350 mesh Mesh; The ceramic layer powder is selected from yttria-stabilized zirconia ceramics, and the particle size after grinding is 550 mesh;

[0020] b) Substrate pretreatment, which includes sandblasting, ultrasonic washing, deionized water cleaning and drying treatment; 150-mesh glass pellets are use...

Embodiment 2

[0025] The specific implementation steps of the preparation method of the novel gradient thermal barrier coating mentioned in the present invention are as follows:

[0026] a) Preparation of spray powder, which includes adhesive layer powder and ceramic layer powder; wherein, the adhesive layer powder is composed of MCrAlY alloy and oxide that can form an oxide film, and the two components need to be prepared separately The main components of MCrAlY alloy are: Co, Cr, Al, S and Ni, the particle size of MCrAlY alloy after grinding is 250 mesh; the oxide that can form an oxide film is magnesium oxide, and the particle size of magnesium oxide after grinding is controlled at 400 mesh mesh; the ceramic layer powder is calcium oxide stabilized zirconia ceramic material, and the particle size after grinding is 600 mesh;

[0027] b) Substrate pretreatment, which includes sandblasting, ultrasonic washing, deionized water cleaning and drying treatment; 150 mesh glass pellets are selecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com