Automatic dismantling and recovering method and device for case packaging belt

A recycling device and recycling method technology, applied in the field of equipment structure, can solve the problems of high cost, large space occupation, high labor intensity, etc., and achieve the effects of easy storage and transportation, small equipment footprint, and efficient dismantling and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

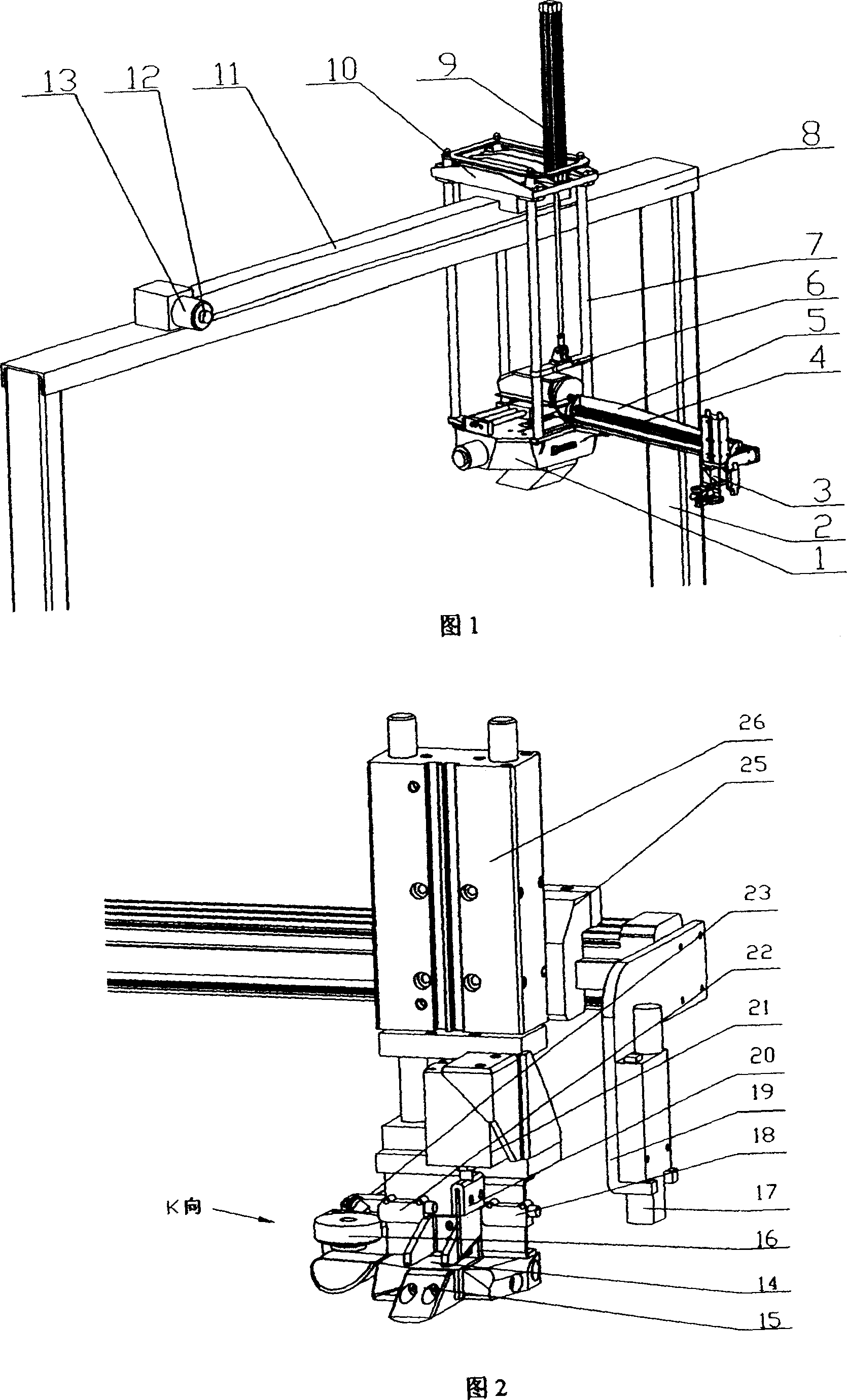

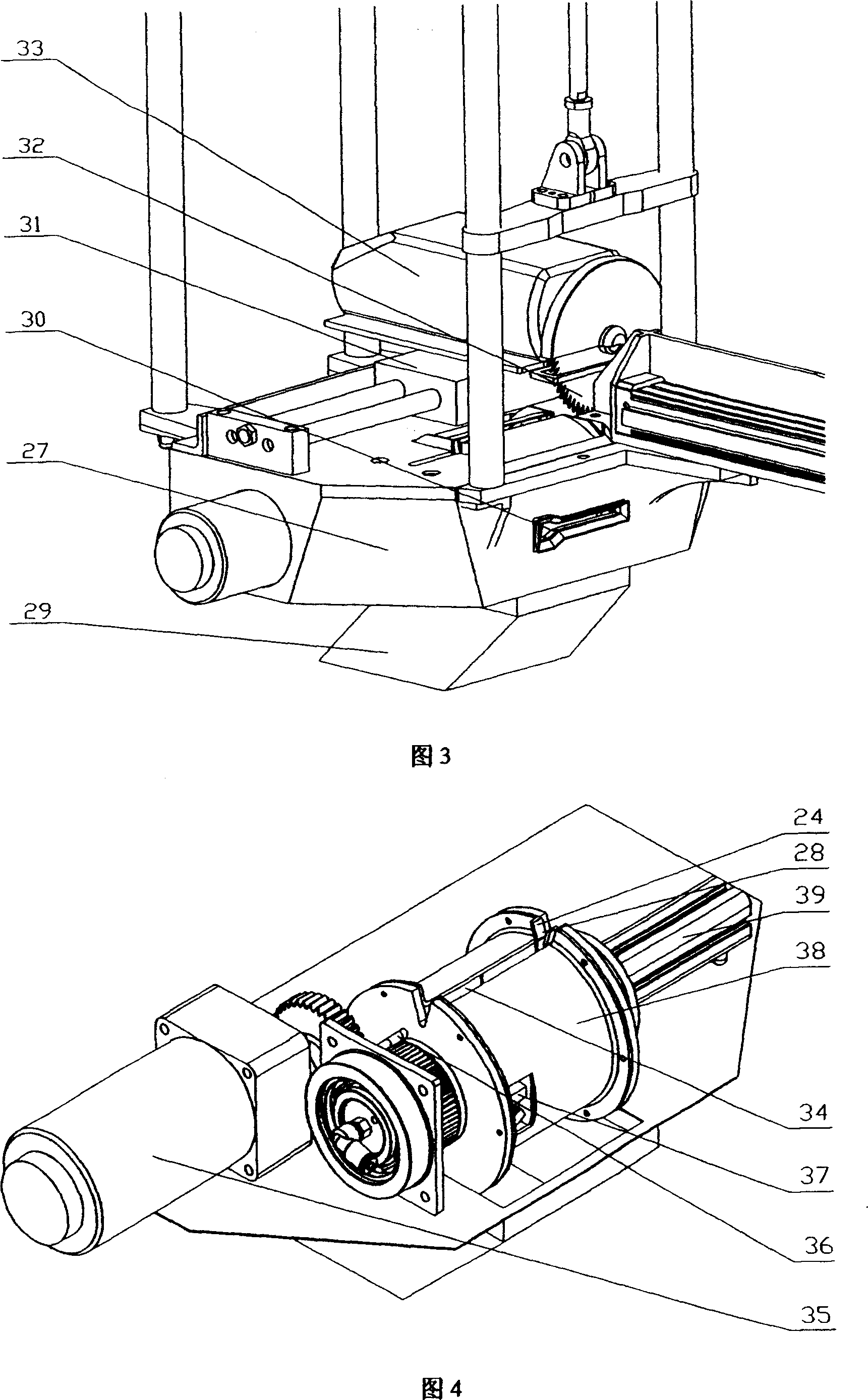

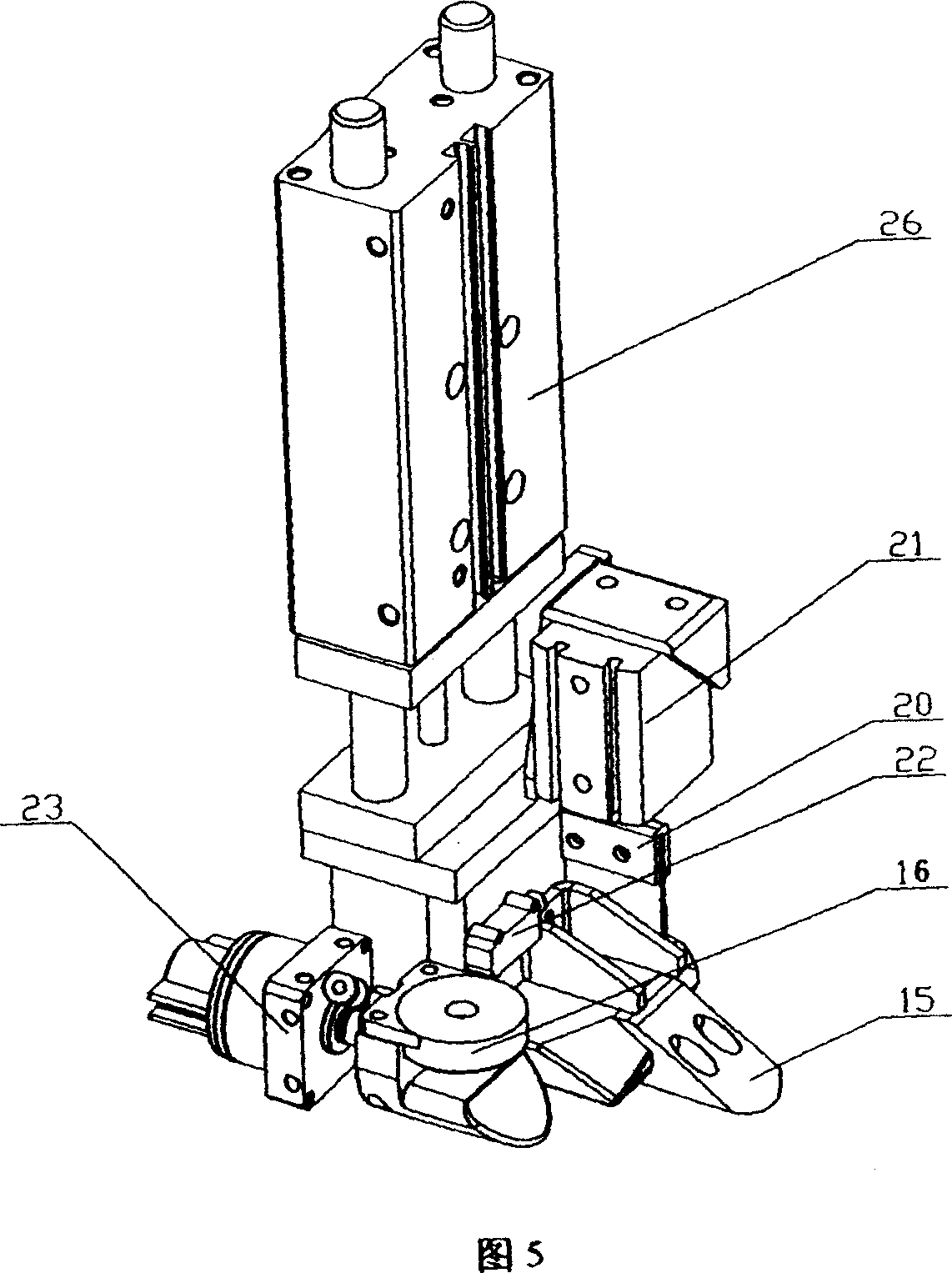

[0016] As shown in Figures 1 to 5, the device of the present invention includes a bracket 2 for installing the entire device, a linear motion guide rail 11 is arranged on the beam 8 of the bracket, a slider 10 is arranged on the guide rail, and a control device is provided at the end of the guide rail. The actuator motor 13 and the displacement sensor 12 that the slide block moves are equipped with a guide rod frame 7 on the slide block 10, and the guide rod frame is composed of four guide rods arranged vertically to form a frame structure, and the guide rods are fixedly connected with longitudinal The pull rod 6, the outer end of the pull rod is connected with the lifting drive element 9 installed on the slide block 10 to drive the guide rod frame up and down. The lower end of the guide rod frame is provided with a recovery device 1 and a horizontal linear drive device 4 that is used to install and remove the device 3 and is perpendicular to the beam 8. The linear drive device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com