Coupling type sewage de-phosphorization purification regeneration treatment technique

A treatment process and coupled technology, applied in the fields of adsorption water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of large sludge discharge and difficulty in disposal of excess sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

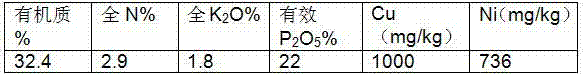

Embodiment 1

[0040] In this embodiment, the sewage discharged from a certain chemical factory in Guangzhou, which is inferior to Class V, is subjected to advanced treatment to reach the level of surface water Class III (TN < 15 mg / L), and the daily treatment capacity is 10 tons.

[0041] The micro-polluted water treatment steps of this embodiment are as follows:

[0042] A coupled sewage dephosphorization purification regeneration treatment process, comprising the following steps:

[0043] a) Precipitation

[0044] The sewage collected by the sewage pipeline is filtered through the coarse grid to remove solid impurities and then enters the sand settling sump.

[0045] The water pump pumps up the sewage from the sand settling tank, passes through the fine grid to filter the mud and sand, and then enters the adjustment tank. Through the circulating water pump and the connected jet device, the perforated aeration pipe installed at the bottom of the tank is used to aerate and agitate the wate...

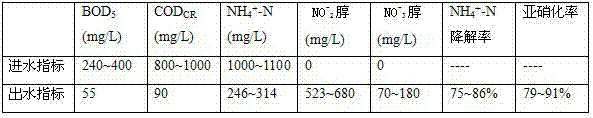

Embodiment 2

[0094] In this embodiment, the sewage discharged from a textile factory in Guangzhou, which is inferior to Class V, is subjected to advanced treatment to reach the level of surface water Class III (TN < 15 mg / L), and the daily treatment capacity is 10 tons.

[0095] A coupled sewage dephosphorization purification regeneration treatment process is characterized in that the method comprises the following steps:

[0096] a) Precipitation

[0097] The sewage collected by the sewage pipeline is filtered through the coarse grid to remove solid impurities and then enters the sand settling sump.

[0098] The water pump pumps up the sewage from the sand settling tank, filters a small amount of mud and sand through a fine grid, and then enters the adjustment tank. Through the circulating water pump and the connected jet device, the perforated aeration pipe installed at the bottom of the tank is used to aerate and stir the water body to maintain The water quality is relatively stable. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com