Two-layer double-sided flexible copper clad laminate and its manufacturing method

A flexible copper clad laminate and double-sided technology, which is applied in the field of two-layer double-sided flexible copper clad laminate and its production, can solve the problems of lower product qualification rate, lower TPI thermal expansion coefficient, lower TPI adhesion, etc. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

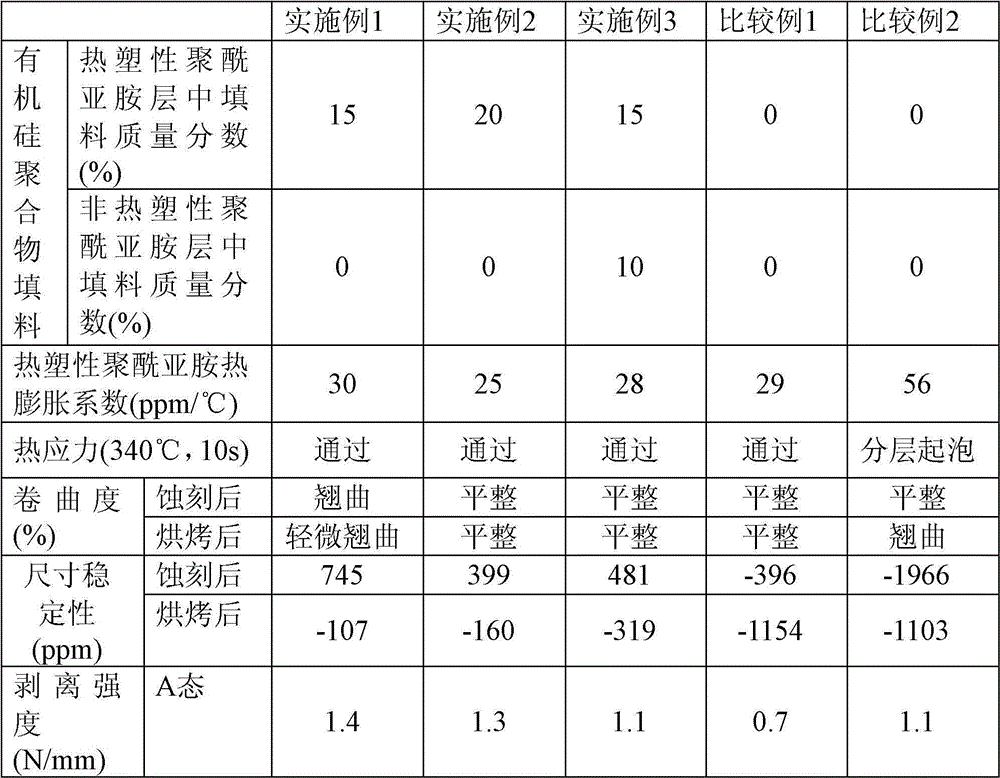

Examples

Synthetic example 1

[0061]Add ODA18.0g (0.090mol), TPE-R15.8g (0.054mol), BAPP14.8g (0.036mol), 180gNMP to a 1000ml three-neck flask equipped with a temperature-controlled water bath and stirring device, and stir at room temperature until solid After completely dissolving, add the prefabricated solution containing 18.5g silicone polymer filler (KMP-605, manufactured by Shin-Etsu Chemical Co., Ltd.) and 100g NMP. 0g (0.09mol), BTDA17.4g (0.054mol) was added to the reactor, rinsed with 80g NMP, and the reaction was stopped after 5 hours of continuous stirring at room temperature to obtain the thermoplastic polyimide precursor polyamic acid solution A1.

Synthetic example 2

[0063] Add ODA18.0g (0.090mol), TPE-R15.8g (0.054mol), BAPP14.8g (0.036mol), 180gNMP to a 1000ml three-neck flask equipped with a temperature-controlled water bath and stirring device, and stir at room temperature until solid After completely dissolving, add the prefabricated solution containing 26.2g organosilicon polymer filler (KMP-597, manufactured by Shin-Etsu Chemical Co., Ltd.) and 100g NMP. 0g (0.09mol), BTDA17.4g (0.054mol) was added to the reactor, rinsed with 80g NMP, and the reaction was stopped after 5 hours of continuous stirring at room temperature to obtain the thermoplastic polyimide precursor polyamic acid solution A2.

Synthetic example 3

[0065] Add ODA18.0g (0.090mol), TPE-R15.8g (0.054mol), BAPP14.8g (0.036mol), 180gNMP to a 1000ml three-neck flask equipped with a temperature-controlled water bath and stirring device, and stir at room temperature until solid After completely dissolving, add the prefabricated solution containing 18.5g of silicone polymer filler (X-52-854, manufactured by Shin-Etsu Chemical Co., Ltd.) and 100g of NMP. ODPA28.0g (0.09mol) and BTDA17.4g (0.054mol) were added to the reactor, rinsed with 80gNMP, stirred at room temperature for 5 hours and then stopped to obtain thermoplastic polyimide precursor polyamic acid solution A3.

[0066] Synthesis example of non-thermoplastic polyimide:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com