Method for manufacturing a metal scrap compression material

A waste metal, final pressure technology, applied in the direction of manufacturing tools, presses, etc., can solve the problems of energy consumption, increase the manufacturing cost of steel products, furnace pollution, etc., to reduce friction and pressure, reduce the incidence of failure, and reduce equipment loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

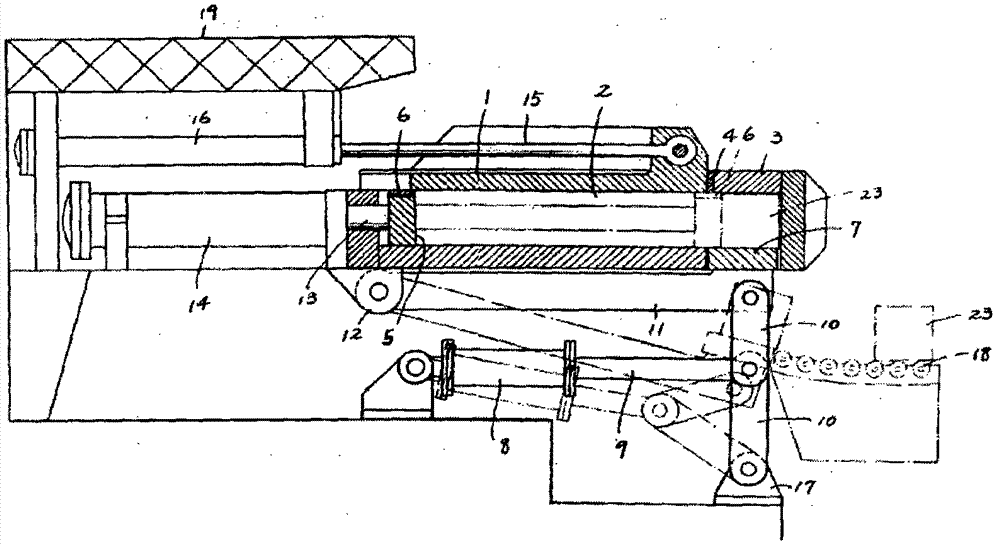

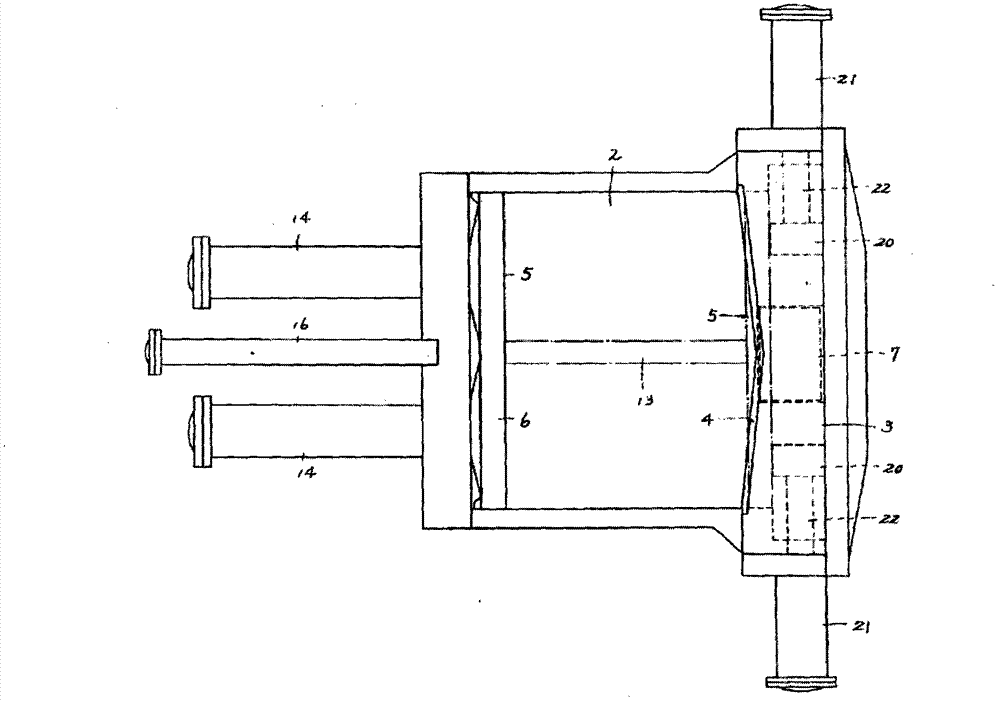

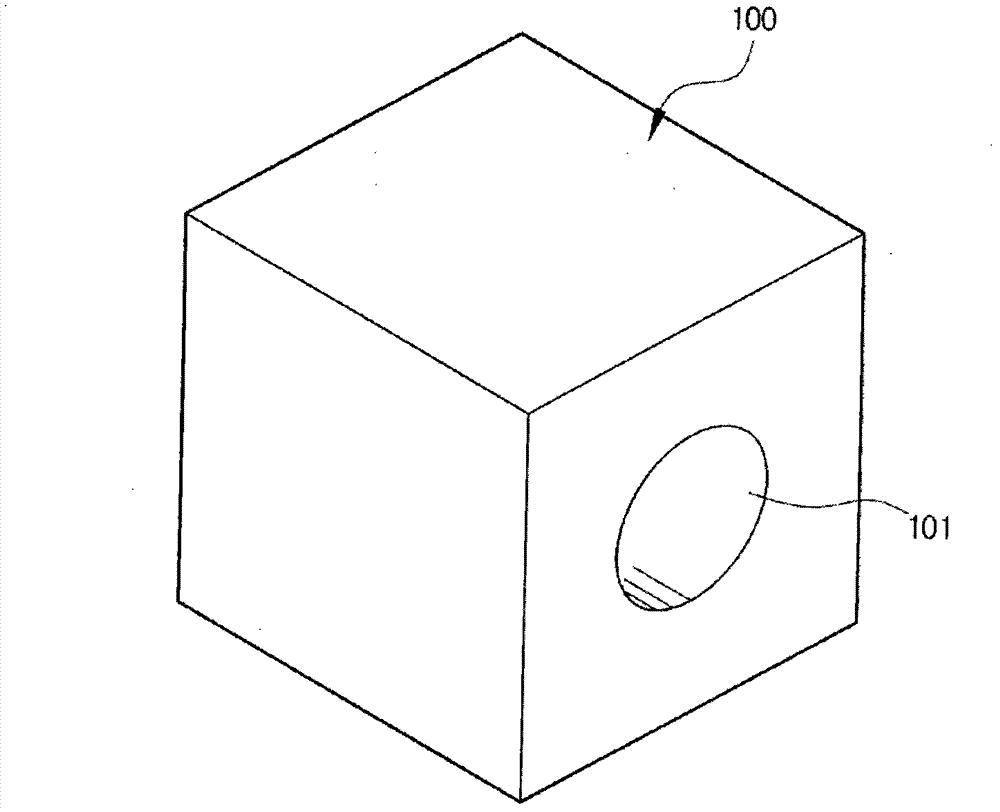

[0033]The manufacturing method of waste metal briquette of the present invention has the stages of feeding waste metal into the compression chamber, relying on the cover working cylinder to close the cover to lock the stage, and relying on the initial pressure working cylinder to initially carry out the initial pressure on the waste metal put into the compression chamber. The initial pressing stage of pressing, the final pressing stage of final pressing the scrap metal briquettes after the initial pressing by the final pressing working cylinder, and the discharging stage of transporting out the scrap metal briquettes that meet the density requirements after final pressing. It is characterized by a pre-positioning stage in which a core is installed in the center of the final pressure compression space before the start of the initial pressure stage to pre-position the punching position; The above-mentioned core forms the through-hole forming stage of the through-hole of the scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com