Nitride fluorescent powder and preparation method thereof

A technology of nitride phosphor and chemical formula, which is applied in the field of phosphor to achieve the effects of improved thermal stability and structural stability, long life, and wide excitation wavelength range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

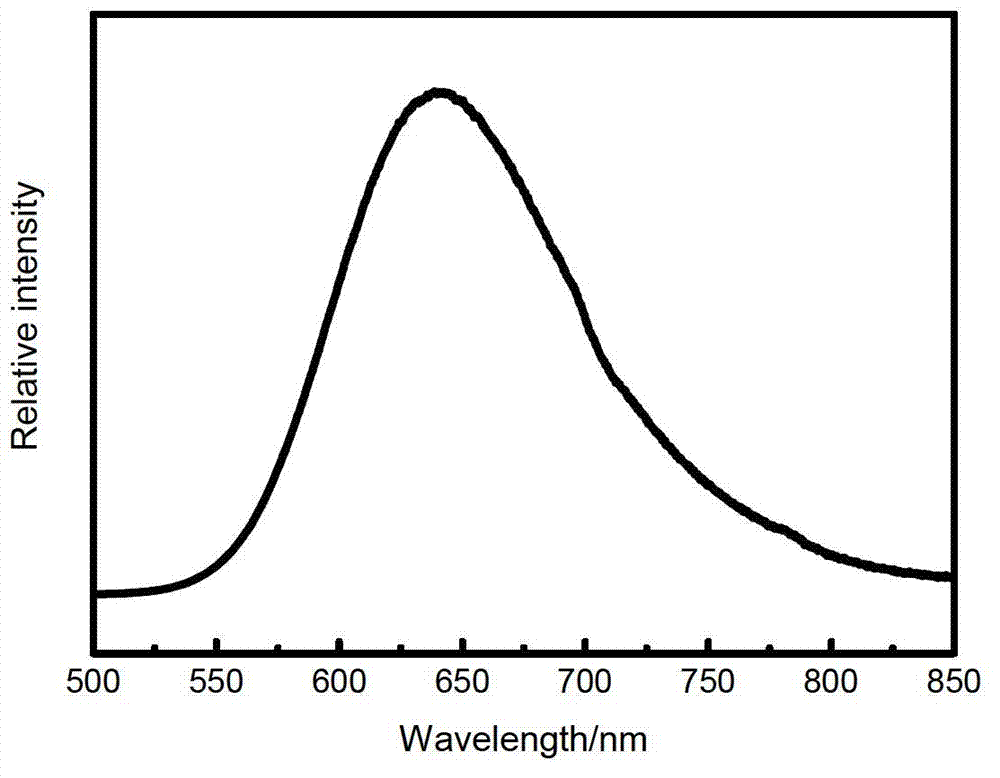

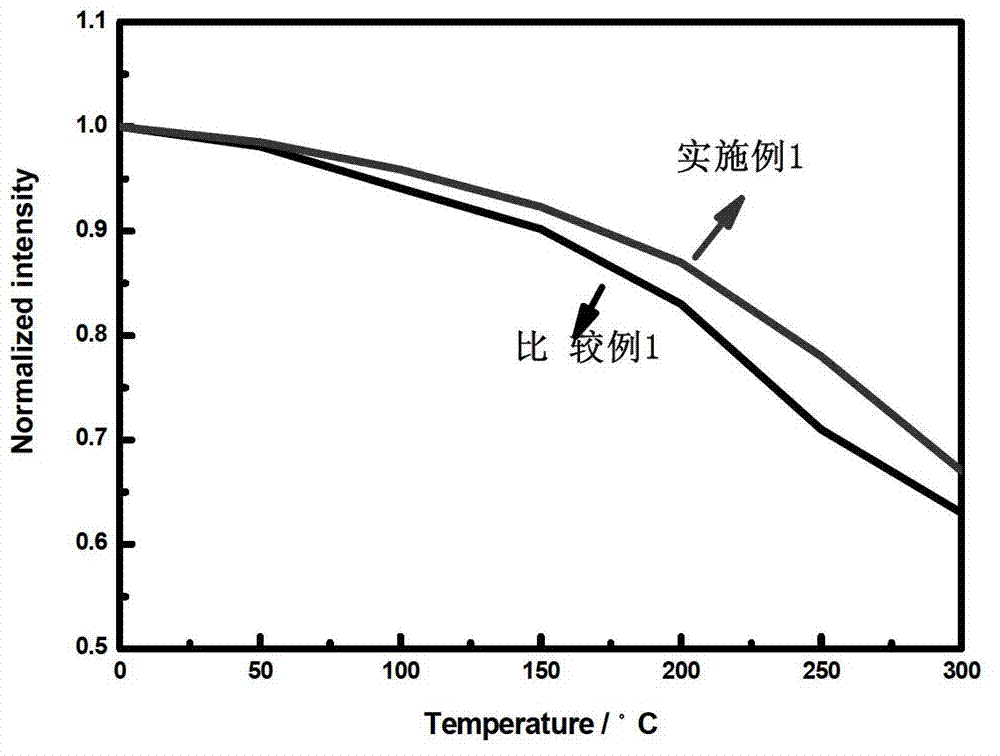

[0034] Weigh Sr 3 N 2 (4N)0.012mol, Ca 3 N 2 (4N)0.0064mol, Si 3 N 4 (4N)0.02mol, AlN(4N)0.06mol, Cu 3 N(4N) 0.0008mol, EuN(4N) 0.0036mol; the above raw materials were mixed and ground in a glove box, put into a molybdenum crucible, and then quickly moved into an atmosphere furnace, and heated at 1800°C under 1MPa NH 3 Insulated in the atmosphere for 5 hours, the resulting product is crushed, pickled to remove impurities, sieved, and dried to obtain Sr 0.6 Ca 0.32 SiAlN 3 :Cu + 0.04 Eu 2+ 0.06 Phosphor. It emits broadband visible light with a peak at 610-690nm under the excitation of blue light, purple light or ultraviolet light, and its emission spectrum is shown in figure 1 , whose temperature dependence is shown in figure 2 .

Embodiment 2

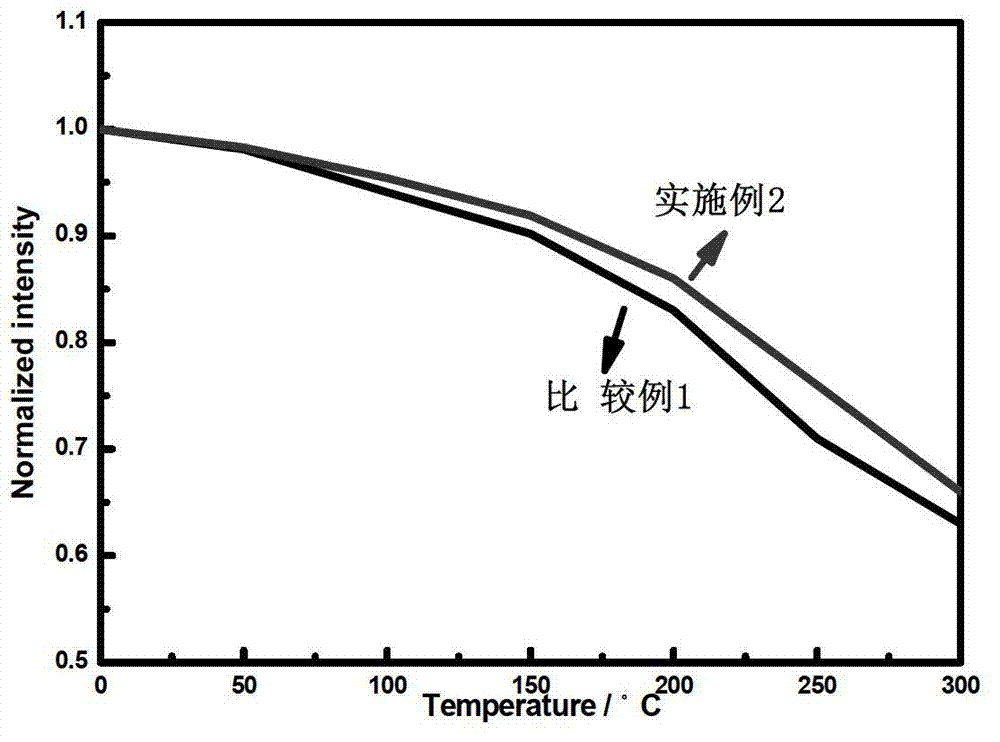

[0038] Weigh and weigh Sr 3 N 2 (4N)0.0124mol, Ca 3 N 2 (4N)0.0064mol, Si 3 N 4 (4N) 0.02mol, AlN(4N) 0.06mol, EuN(4N) 0.0036mol; the above raw materials were mixed and ground in the glove box and put into the molybdenum crucible, and then quickly moved into the atmosphere furnace, at 1800 ℃ 0.1MPa NH 3 Insulated in the atmosphere for 5 hours, the resulting product is crushed, washed to remove impurities, classified by air flow, and dried to obtain Sr 0.6 Ca 0.32 SiAlN 3 :Mn2+ 0.02 Eu 2+ 0.06 Phosphor. For a comparison of the emission temperature characteristics of Example 2 and Comparative Example 1, see image 3 .

Embodiment 3

[0040] Weigh Ca 3 N 2 (4N)0.0552mol, Si 3 N 4 (4N)0.02mol, AlN(4N)0.06mol, Cu 3 N (4N) 0.0008mol, EuN (4N) 0.0036mol; put the above raw materials into the molybdenum crucible after mixing and grinding in the glove box, and then quickly move it into the atmosphere furnace, in 2100 ℃ 5MPa nitrogen-hydrogen mixed atmosphere (N 2 / H 2 The volume ratio is 70:30) for 2 hours, and the obtained product is crushed, alkali washed to remove impurities, hydraulically classified, and dried to obtain Ca 0.92 SiAlN 3 :Cu + 0.04 Eu 2+ 0.06 Phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com