Alprostadil lyophilized microemulsion, and preparation method and application thereof

A technology of alprostadil and freeze-dried microemulsion, applied in the field of alprostadil freeze-dried microemulsion and its preparation, can solve the problems of insufficient clinical safety and stability of preparations, complicated process of alprostadil dry emulsion, etc. Duration of efficacy, reduced irritation, reduced impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

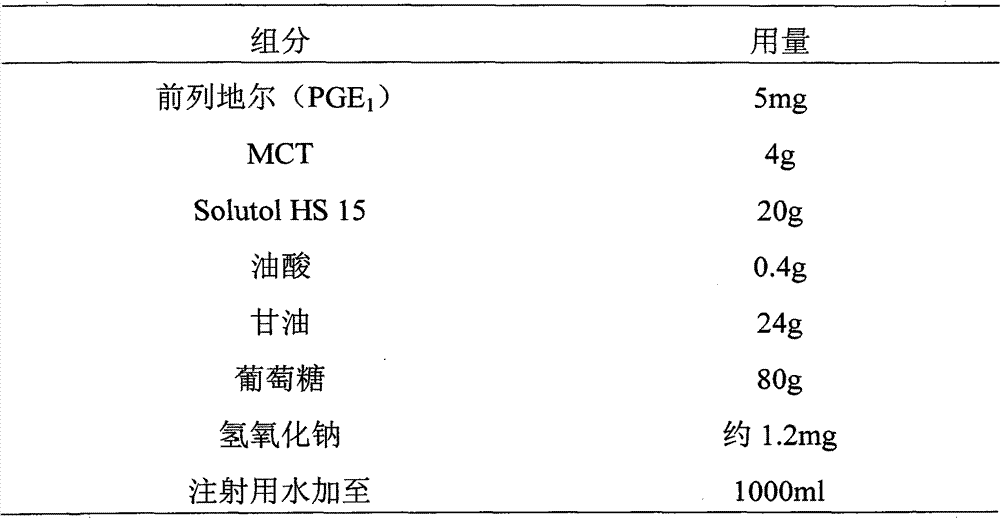

[0023] prescription:

[0024]

[0025] crafting process:

[0026] (1) Mix and heat MCT, alprostadil, oleic acid, glycerin and Solutol HS 15 to dissolve them all, as the oil phase, add glucose to water, stir to dissolve, and use it as the water phase;

[0027] (2) At 30-50°C, slowly add the water phase to the oil phase while stirring to form a microemulsion, and then stir for 0.5h to form a stable and uniform microemulsion;

[0028] (3) adjust the pH of the microemulsion to 6.0-7.0, then pass the microporous membrane of the gained microemulsion through a 0.22 μm microporous membrane, and filter and sterilize;

[0029] (4) Finally, the sterilized microemulsion is freeze-dried to remove moisture, and then under the protection of nitrogen, the freeze-dried product is covered with an aluminum cover and taken out of the box;

[0030] (5) Steps (1) to (4) are all operated under nitrogen protection.

Embodiment 2

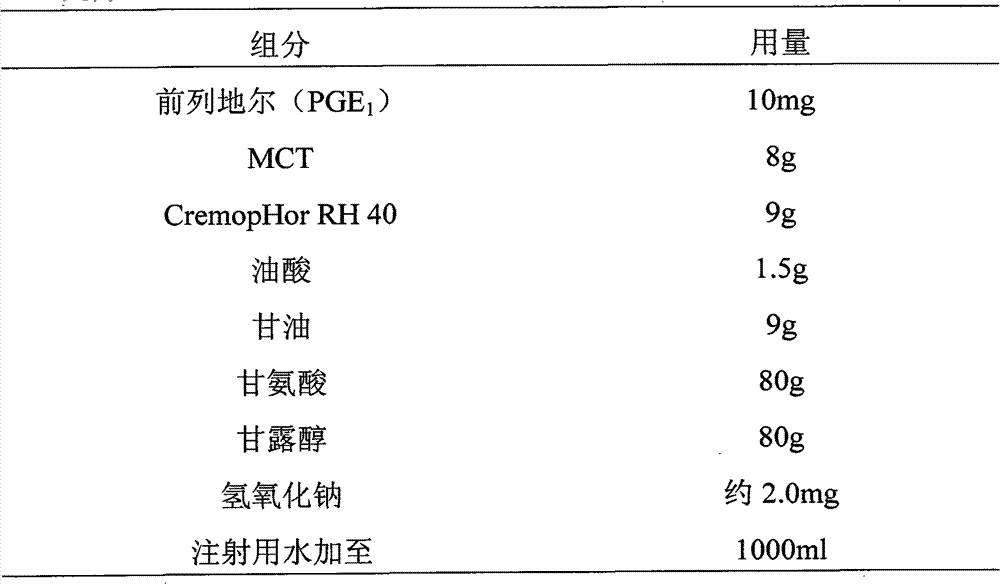

[0032] prescription:

[0033]

[0034] crafting process:

[0035] (1) Mix and heat MCT, alprostadil, oleic acid, glycerin, and Cremophor RH 40 to dissolve them all, as the oil phase, add glycine, mannitol, etc. into water, stir to dissolve, and use it as the water phase;

[0036] (2) At 30-50°C, slowly add the water phase to the oil phase while stirring to form a microemulsion, and then stir for 0.5h to form a stable and uniform microemulsion;

[0037] (3) adjust the pH of the microemulsion to 6.0-7.0, then pass the microporous membrane of the gained microemulsion through a 0.22 μm microporous membrane, and filter and sterilize;

[0038] (4) Finally, the sterilized microemulsion is freeze-dried to remove moisture, and then under the protection of nitrogen, the freeze-dried product is covered with an aluminum cover and taken out of the box;

[0039] (5) Steps (1) to (4) are all operated under nitrogen protection.

Embodiment 3

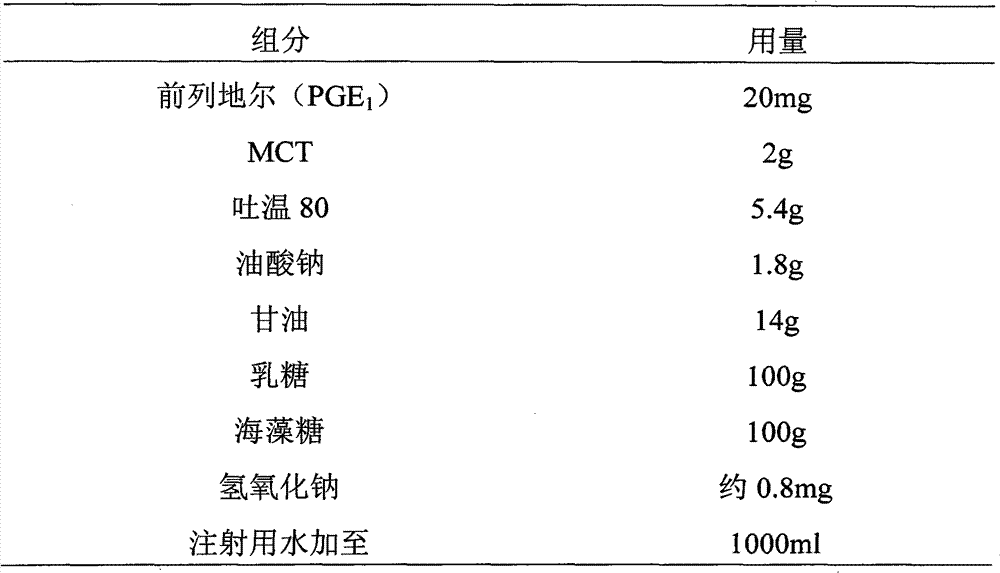

[0041] prescription:

[0042]

[0043] crafting process:

[0044] (1) MCT, alprostadil, sodium oleate, glycerin, and Tween 80 are mixed and heated to make them all dissolve, and as the oil phase, lactose, trehalose, etc. are added to water, stirred to dissolve, and used as the water phase;

[0045] (2) At 30-50°C, slowly add the water phase to the oil phase while stirring to form a microemulsion, and then stir for 0.5h to form a stable and uniform microemulsion;

[0046] (3) adjust the pH of the microemulsion to 6.0-7.0, then pass the microporous membrane of the gained microemulsion through a 0.22 μm microporous membrane, and filter and sterilize;

[0047] (4) Finally, the sterilized microemulsion is freeze-dried to remove moisture, and then under the protection of nitrogen, the freeze-dried product is covered with an aluminum cover and taken out of the box;

[0048] (5) Steps (1) to (4) are all operated under nitrogen protection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com