Integral type steel magnet of high-performance permanent magnetic synchronous motor

A permanent magnet synchronous motor, high-performance technology, applied in synchronous machine parts, magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc. Demagnetization and other problems can reduce production costs, improve the effect of magnetization, and improve the effect of excitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

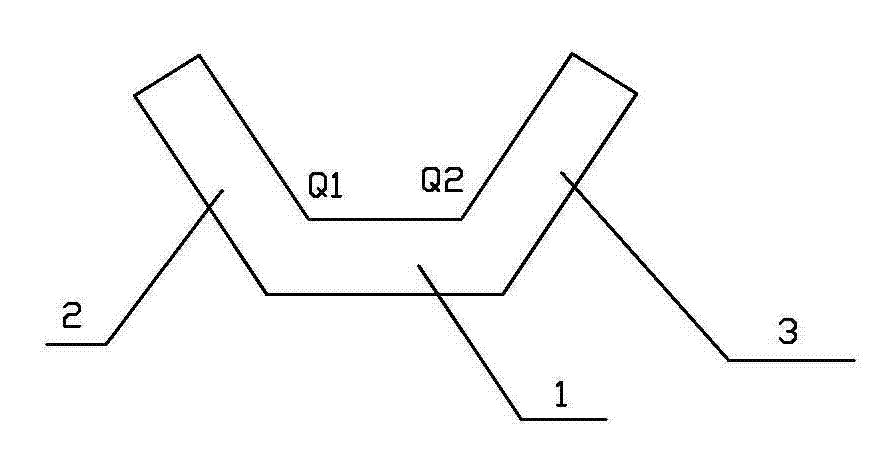

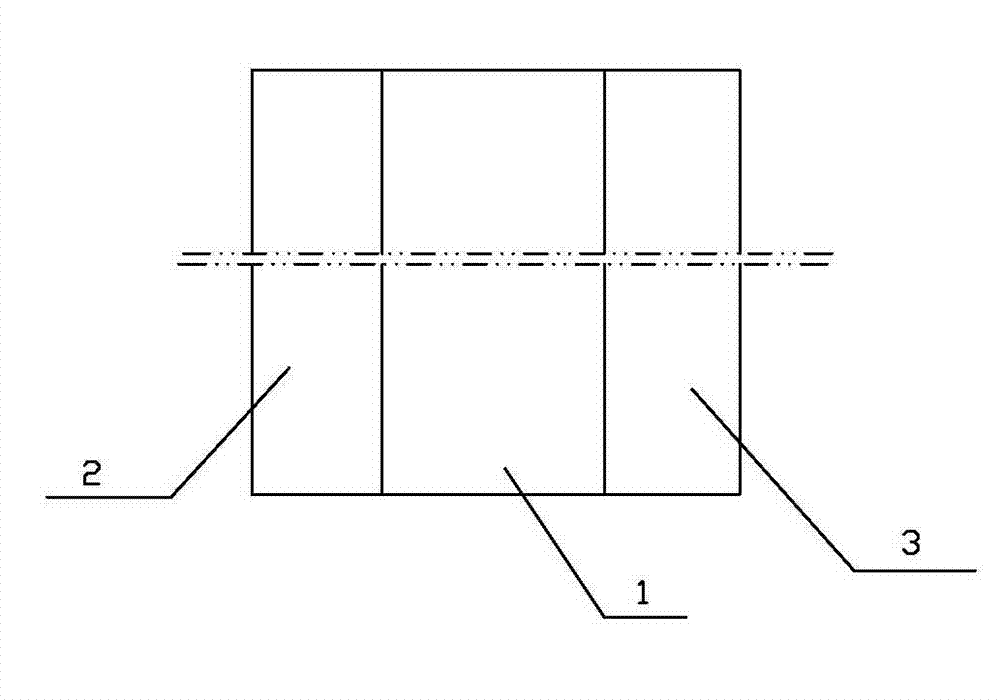

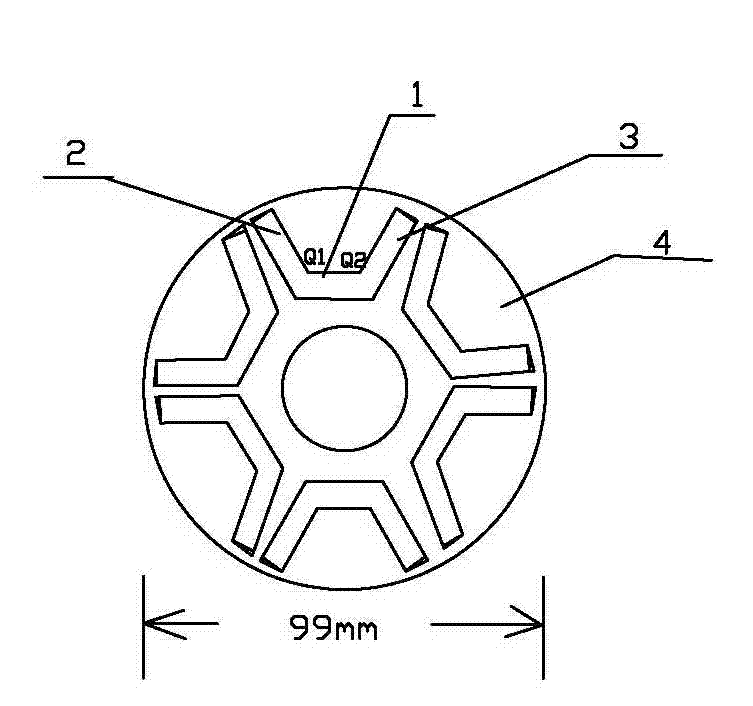

[0018] figure 1 , figure 2 An example is given; image 3 A schematic diagram of the rotor for a 4KW high-performance permanent magnet synchronous motor is given; Figure 4 A schematic diagram of a rare-earth material "V"-shaped rotor currently used in a 4KW high-performance permanent magnet synchronous motor is given. The integral magnet of the high-performance permanent magnet synchronous motor includes a flat magnet 1, which is characterized in that: the left edge of the flat magnet 1 is provided with an angle θ with the flat magnet 1 1 , and connected as one left flat magnetic steel 2; the right edge of the flat magnetic steel 1 is provided with an angle θ with the flat magnetic steel 1 2 , and connected as one right flat magnet 3; the midline of the flat magnet 1 intersects the midline of the left flat magnet 2 and the midline of the right flat magnet 3 on a straight line; the flat magnet 1, The left flat magnet 2 and the right flat magnet 3 are pressed and sintered a...

Embodiment 2

[0027] The invention is applied to the rotor of a 6KW high-performance permanent magnet synchronous motor. Its structure and method of use are the same as in Example 1. What has been changed is that according to the requirements of a 6KW high-performance permanent magnet synchronous motor, the thicknesses of the flat magnet 1, the left flat magnet 2 and the right flat magnet 3 are both 7mm; the included angle θ 1 and angle θ 2 Equal, both 124.5 degrees. In the operation comparison of the motor, the rated current is reduced by 6.1%; the efficiency is increased by 7.98%.

Embodiment 3

[0029] The invention is applied to the rotor of the 8KW high-performance permanent magnet synchronous motor. Its structure and method of use are the same as in Example 1. The changes, according to the requirements of the 8KW high-performance permanent magnet synchronous motor, the thickness of the flat plate magnet 1, the left flat magnet 2 and the right flat magnet 3 are both 8mm; the included angle θ 1 and angle θ 2 Equal, both 125.5 degrees. In the operation comparison of the motor, the rated current is reduced by 7.3%; the efficiency is increased by 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com