Silicon-manganese-calcareous shale deoxidizer and preparation method thereof

A technology of calcareous shale and silicon-manganese-calcium, which is applied in the field of steelmaking, can solve problems such as unsmoothness and high cost, and achieve the effects of smooth process, reduced content, and lower steelmaking cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: Silico-manganese calcareous shale deoxidizer, the parts by weight of its raw materials are: quartz sand 45, black manganese ore 18, lapis lazuli 8, limestone 55, calcareous shale 25, iron filings 8, fly ash 15. Vermiculite 12. Sepiolite 8.

[0011] The preparation method of the silico-manganese calcium shale deoxidizer comprises the following steps: weighing each raw material according to the weight portion of the constituent raw materials, mixing, smelting at a high temperature of 2500-2800 DEG C for 2-3 hours, cooling and crushing to obtain.

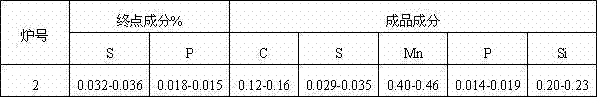

[0012] The following is the deoxidation test, the test steel is low carbon steel, used in 2# furnace, 1.40kg / t steel

[0013] Hot metal conditions:

[0014] [S]S% [P]% 0.037-0.032 0.190-0.150

[0015] Deoxygenation result:

[0016] serial number furnace number Addition amount of the present invention (kg) Oxygen content (PPm) 1 2-12807 20 40.21 2 2-12808 20 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com