Intumescent flame retardant functional silicate and preparation method thereof

An intumescent flame retardant and a functionalized technology, applied in the field of preparation of multifunctional flame retardant fillers, can solve the problems of large addition amount, poor dispersion of polymer matrix, large amount of smoke, etc., to promote reinforcement and improve flame retardant performance. , the effect of promoting dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

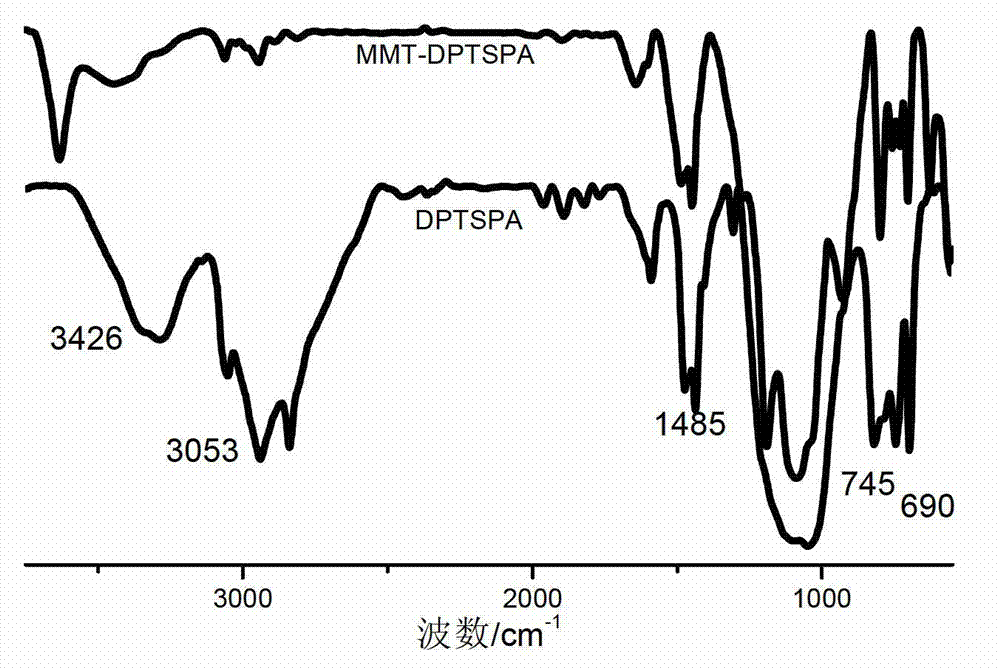

[0037] (1) Weigh 22.1g (0.1mol) of Y-aminopropyltriethoxysilane and 50mL of toluene into a 250mL four-neck flask, blow in nitrogen, then add 10.1g (0.1mol) of triethylamine for continuous Stir; 22g (0.1mol) of diphenylphosphorus chloride was dissolved in 25mL of toluene, and then slowly added dropwise into the four-necked flask with a constant pressure dropping funnel, the dropping time was 2h, and the temperature rose to 65 ℃, under the protection of nitrogen, continue to react for 10 hours to obtain the product, filter, and distill the filtrate under reduced pressure to obtain the viscous product N-(P,P'-diphenyl)phosphoryl-(3-triethoxysilyl) Propylamine) (DPTSPA) 36.45g, the yield is 90%.

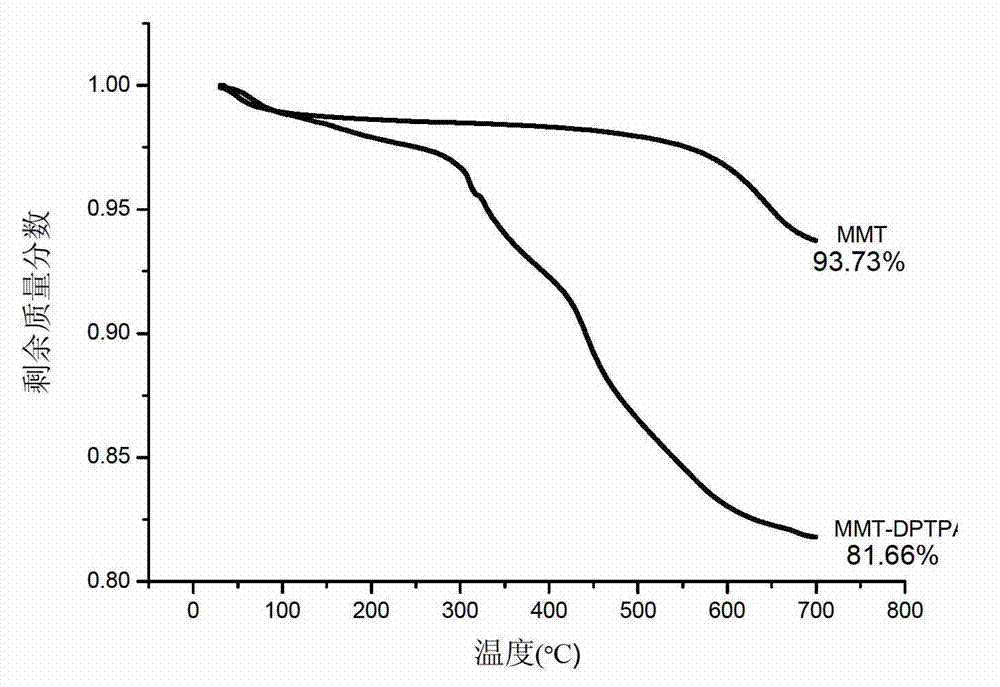

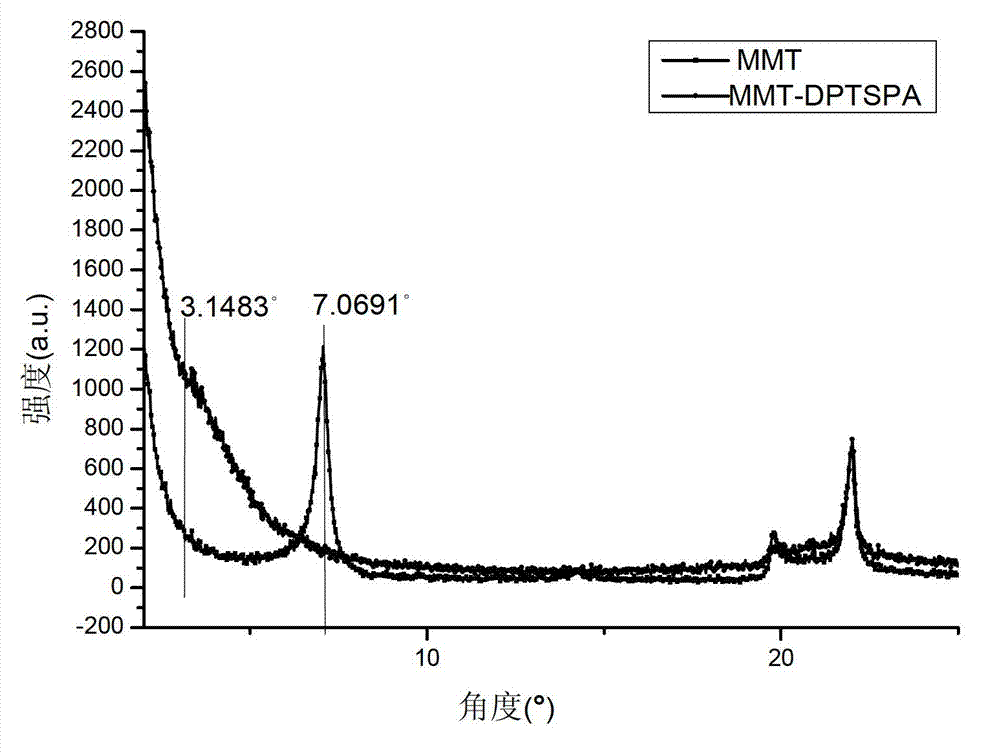

[0038](2) 50g of montmorillonite was pre-ground on a ball mill for 30min, 15g of synthetic viscous product (DPTSPA) was added dropwise to 15mL of 95% (volume concentration) ethanol, and ultrasonically dispersed for 30min (ultrasonic frequency was 20kHz, ultrasonic power was 400W) Add dr...

Embodiment 2

[0043] (1) Weigh 25g of montmorillonite and stir vigorously to disperse it in 100mL of absolute ethanol, then add dropwise 45% ammonia water to adjust the pH value to 9-10, and dissolve 10g of Y-aminopropyltriethoxysilane in 20mL of 95% ethanol (volume concentration) ultrasonically disperse for 30min (ultrasonic frequency is 20kHz, ultrasonic power is 400W), then add to the montmorillonite solution, continue stirring at 60°C for 12h, centrifuge, extract the precipitate with acetone for 48h, and vacuum dry at 80°C for 4h to obtain The product, the grafting rate of silane coupling agent is about 15wt%.

[0044] (2) 20g of amino-modified montmorillonite and 80mL of toluene were placed in a 250mL four-neck flask, nitrogen was introduced, and 0.1mol of sodium carbonate was added, stirring continuously; 22g (0.1mol) of diphenylphosphorous chloride was dissolved in 25mL of toluene, and then slowly drop it into a four-neck flask with a constant pressure dropping funnel, the dropping t...

Embodiment 3

[0047] (1) Weigh 50g of halloysite and stir vigorously to disperse it in 100mL of absolute ethanol, then add dropwise 45% ammonia water to adjust the pH value to 9-10, 23g of N-β(aminoethyl)-Y-aminopropyltrimethyl Oxysilane was dissolved in 20mL 95% ethanol and ultrasonically dispersed for 30min (ultrasonic frequency 20kHz, ultrasonic power 400W), then added to the halloysite solution, stirred at 60°C for 10h, centrifuged, and the precipitate was extracted with acetone for 48h, 80 The product was dried under vacuum at ℃ for 4 hours, and the grafting rate of the silane coupling agent was about 8wt%.

[0048] (2) Put 30g of amino-modified halloysite and 80mL of toluene in a 250mL four-neck flask, blow nitrogen into it, then add 0.05mol of sodium bicarbonate, and keep stirring; 7.7g (0.05mol) of phosphorus oxychloride dissolves in 25mL of acetonitrile, and then slowly drop it into a four-neck flask with a constant pressure dropping funnel. The time for dropping is not less than 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com