Titanium-base methanated catalyst, preparation method thereof and application thereof

A catalyst, hydromethanation technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effect of improving catalytic activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

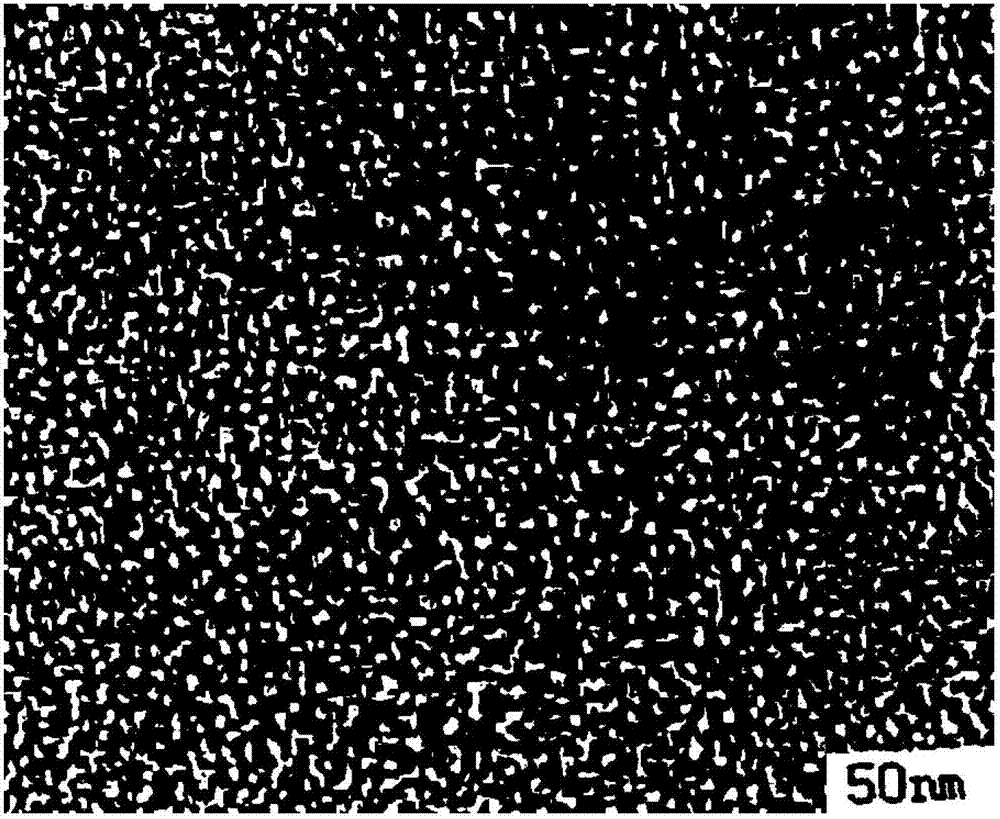

Image

Examples

Embodiment 1

[0074] A high concentration of CO, CO 2 The hydromethanation catalyst is prepared by the following method:

[0075] Get 148 grams of synthetic basic nickel carbonate (NiO content 13.5%, the same below) prepared above, commercially available fumed white carbon black (nanometer SiO 2 Containing 98%, the same below) 5.1 grams, titanium-zirconium powder (based on 76%, the same below) 39.5 grams, commercially available magnesium oxide (based on 95%, the same below) 31.6 grams, washed shielding metatitanic acid (TiO 2 Content by 46.6%, the same below) 32.2 grams. The above components are thoroughly mixed and evenly roasted in a muffle furnace at 500° C. for 2 hours, and crushed into fluid powders with a size of about 60-80 mesh to obtain a catalyst.

[0076] The catalyst of above-mentioned preparation contains NiO 20wt% (mass percentage content), SiO 25wt%, titanium-zirconium composite carrier 30wt%, magnesium oxide 30%, titanium dioxide 15wt%.

Embodiment 2

[0081] A high concentration of CO, CO 2 The hydromethanation catalyst is prepared by the following method:

[0082] Get 148 grams of the above-mentioned synthetic basic nickel carbonate prepared above, 5.15 grams of commercially available microporous heat-insulating material (according to 97%, the same below), 39.5 grams of titanium-zirconium powder, 31.6 grams of commercially available magnesium oxide, water-washed shielding partial titanium Acid 32.2 grams. The above-mentioned components are thoroughly mixed and evenly roasted in a muffle furnace at 500° C. for 2 hours, and crushed into fluid powders with a size of about 60-80 mesh to obtain a catalyst.

[0083] The catalyst prepared above contains 20% by weight of NiO, 5% by weight of microporous heat insulating material, 30% by weight of titanium-zirconium composite carrier, 30% by weight of magnesium oxide and 15% by weight of titanium dioxide.

[0084] Adding graphite powder accounting for 1% by weight of the catalyst ...

Embodiment 3

[0088] A high concentration of CO, CO 2 The hydromethanation catalyst is prepared by the following method: get 148 grams of synthetic basic nickel carbonate prepared above, 5.1 grams of commercially available fumed white carbon black, 39.5 grams of titanium-zirconium powder, 31.6 grams of commercially available magnesium oxide, wash with water Shield metatitanic acid 21.5 grams, lanthanum nitrate (containing La 2 o 3 36.8%, the same below) 13.5 grams, the above components are fully mixed, then roasted in a muffle furnace at 500 ° C for 2 hours, and broken into fluidity, about 60-80 mesh size powder, to obtain the catalyst.

[0089] The catalyst of above-mentioned preparation contains NiO20wt%, nanometer SiO 2 5wt%, titanium-zirconium composite carrier 30wt%, magnesium oxide 30%, titanium dioxide 10wt%, lanthanum oxide 5wt%.

[0090] Adding graphite powder accounting for 1% by weight of the catalyst as a tableting lubricant, mixing with the catalyst powder evenly, and tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com