Cyclohexanone-oxime vaporizing method

A technology of cyclohexanone oxime and vaporizer, which is applied in chemical instruments and methods, chemical/physical processes, feeding devices, etc., can solve the problems of increasing the risk of coking, low vaporization temperature, etc., and achieve coking elimination, convenient operation and control, Simple effect of gasification method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

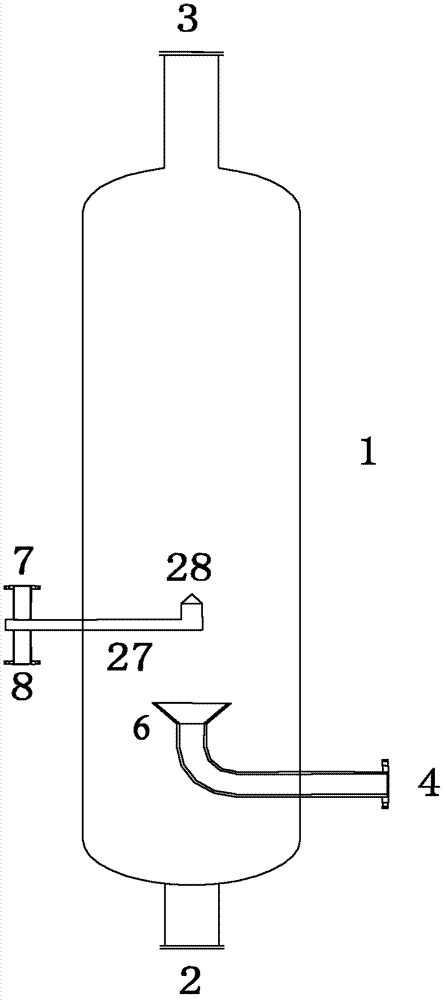

[0036] In the method provided by the present invention, the vaporization device can adopt the following various embodiments, one of the embodiments: such as figure 1Shown: the vaporization device includes a vaporizer housing 1, an atomizing spray gun 27 extending into the vaporizer, and a high-temperature gas inlet 4, which is open to the gas-phase material outlet 3 of the vaporizer housing 1; wherein, the atomizing spray gun 27 Including the gun body and the atomizing nozzle 28, the inlet of the atomizing spray gun 27 is connected to the liquid cyclohexanone oxime feed port, and the high temperature gas inlet 4 is located in the opening in the vaporizer housing and is provided with a high temperature gas distributor 6. The position is such that the introduced high temperature gas comes into quick and sufficient contact with the liquid sprayed from the atomizing spray gun 27 .

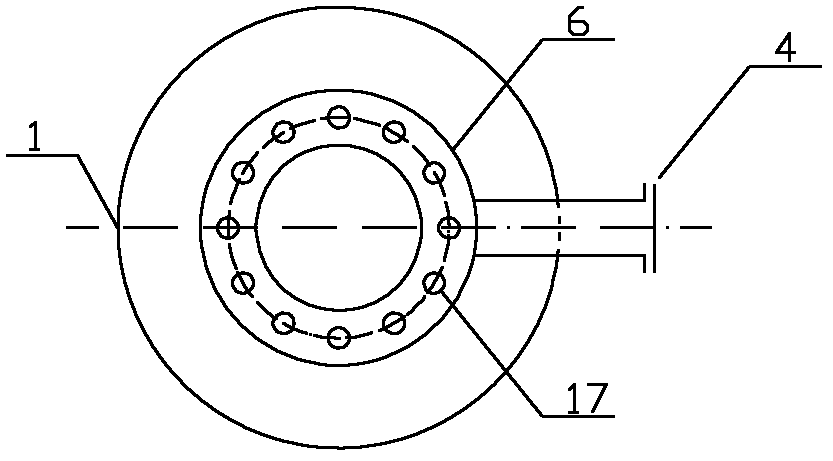

[0037] In the method provided by the present invention, the high-temperature gas distributor 6 is a...

Embodiment 1

[0058] as attached figure 1 As shown, cyclohexanone oxime was introduced into the vaporization device from the liquid feed port, the feed amount was 100Kg / h, the feed temperature was 120°C, and the feed pressure was 0.4MPa. The liquid phase feed is first mixed with the mixed gas nitrogen and then introduced into the atomizing spray gun from the liquid feed port, and the mixed nitrogen feed amount is 5Nm 3 / h, the feed pressure is 0.4MPa. The atomizing medium nitrogen is introduced from the gas feed port of the atomizing spray gun, and the flow rate is 37Nm 3 / h, the pressure is 0.25MPa (absolute pressure), and the mixed fluid enters the cavity of the atomizing spray gun. Under the action of nitrogen atomizing medium, cyclohexanone oxime was rapidly atomized into small droplets. The high-temperature nitrogen is introduced through the high-temperature gas inlet, and is introduced into the vaporization device through the high-temperature gas distributor, and the nitrogen flow ...

Embodiment 2

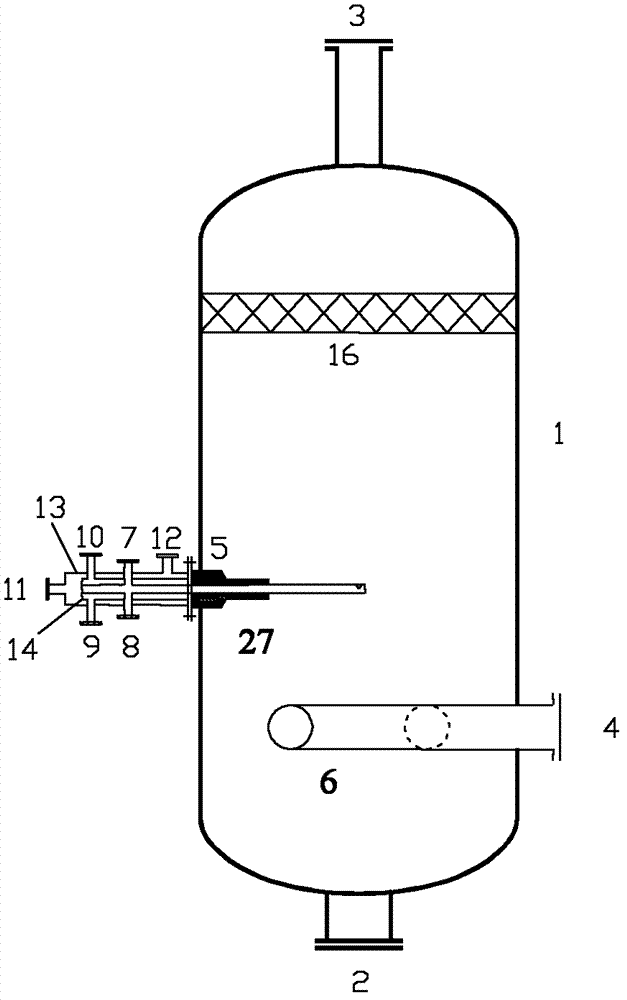

[0060] as attached figure 2 As shown in the figure, a heating water jacket and a heating gas jacket are arranged in sequence outside the atomizing spray gun, the temperature of the heating water is 90°C, and the temperature of the heating water is 120°C. Cyclohexanone oxime was introduced into the atomization spray gun from the liquid feed port, the feed amount was 100Kg / h, the feed temperature was 120°C, and the feed absolute pressure was 0.6MPa. Cyclohexanone oxime is rapidly atomized into small droplets into the vaporizer in the atomizing spray gun. The high-temperature nitrogen is introduced through the high-temperature gas inlet, and is introduced into the vaporization device through the high-temperature gas distributor, and the nitrogen flow rate is 1046kg / h. The droplets of cyclohexanone oxime contacted with nitrogen at a high temperature of 430°C, vaporized instantly, and the temperature after vaporization was 352°C. The vaporized cyclohexanone oxime gas is led out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com