Method for desulfurizing high-sulphur boiler flue gas to prepare high-purity ammonium bisulfite

An ammonium bisulfite and boiler flue gas technology, applied in ammonium sulfite, separation methods, chemical instruments and methods, etc., can solve the problems of large dehydration resistance, low absorption efficiency, large ammonia escape loss, etc. The effect of desulfurization efficiency, high desulfurization efficiency and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

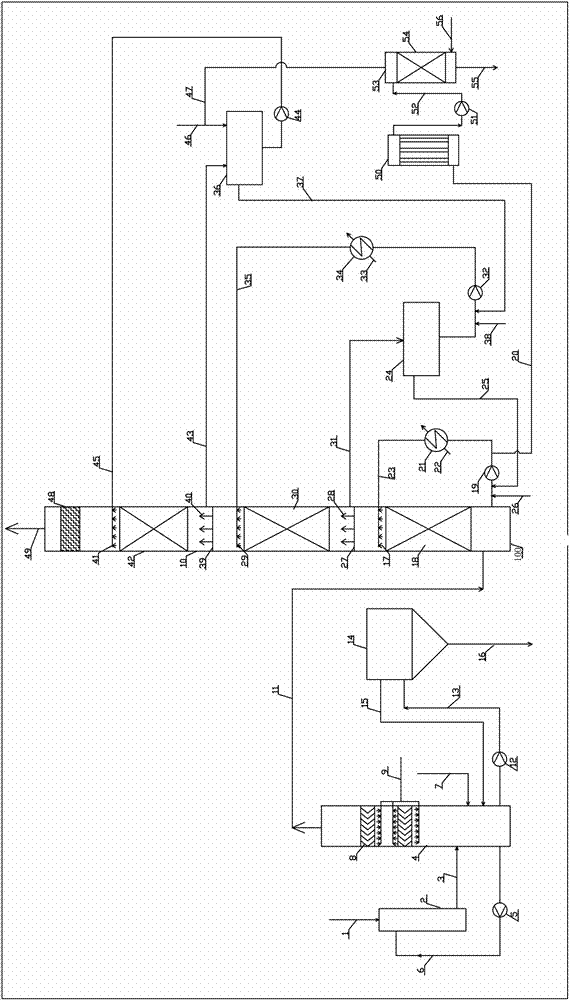

[0038] High-sulfur boiler flue gas desulfurization method for preparing high-purity ammonium bisulfite, such as figure 1 As shown, the method is as follows:

[0039] After high-sulfur coal-fired or oil-fired boiler flue gas is dried by electrostatic precipitator or bag filter, it is sent to wet scrubber 2 such as venturi or power wave by induced draft fan via pipeline 1 for dust removal and cooling, and the scrubber comes out The gas-liquid mixture enters the gas-liquid separation tower 4 through the line 3, the lower liquid is sent back to the scrubber 2 by the scrubber circulating pump 5 through the line 6, and the external tap water is added to the lower part of the tower from the line 7 as makeup water for washing, and the upper flue gas After the double-layer folded demister 8 removes the entrained liquid droplets, it is sent to the desulfurization tower 100 through the pipeline 11, and the flushing water of the demister 8 is sent from the pipeline 9 to the demister for regul...

Embodiment 2

[0046] SO in flue gas of high-sulfur coal-fired boiler 2 Content 25000 mg / Nm 3 , Temperature 170℃, flow rate 80,000Nm 3 / h, the flue gas is sent to the Venturi scrubber by the induced draft fan and the booster fan after the four-stage electrostatic precipitator, and the circulating fluid sent by the washing circulation pump is 200m 3 / h wet scrubbing, liquid-gas ratio 2.5, gas-water mixture enters the gas-liquid separation tower, the temperature drops to 55℃, the flue gas enters the lower part of the first-stage desulfurization tower after the mist is removed by the two-stage folded plate demister with flushing. Part of the still liquid in the gas-liquid separation tower (200m 3 / h) It is used to pump the venturi washing cycle through the washing cycle, part of it (100m 3 / h) Send the inclined plate inclined tube settler to separate, the clear liquid at the upper part of the settler is returned to the gas-liquid separation tower for recycling, and the acid water containing dust an...

Embodiment 3

[0048] SO in flue gas of coal-fired boiler 2 Content 15000 mg / Nm 3 , Flow 240000Nm 3 / h, washing circulating fluid flow rate 600m 3 / h, liquid-gas ratio 2.5, part of the liquid in the gas-liquid separation tower (600m 3 / h) It is used to pump the venturi washing cycle through the washing cycle, part of it (300m 3 / h) Send the inclined plate inclined tube settler to separate, and the acid water containing dust and mud at the bottom has a flow rate of 9m 3 / h to send sewage treatment, first-stage ammonia water 0.60m 3 / h and the absorption liquid from secondary absorption 5.90m 3 / h, the first stage of absorption is high SO 2 / NH 3 的ammonium bisulfite solution, SO 2 / NH 3 Is 0.92, the total sulfite concentration is 575g / L, the ammonium sulfate produced by the oxidation of ammonium sulfite is 42 / g / L, the still liquid of the first-stage desulfurization tower is pumped out by the first-stage circulating pump, and most of the (1200 m 3 / h) as the circulating fluid, the rest (6.2m 3 / h) U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com