Light emitting diode by taking graphene film as current carrier injection layer

A graphene film, light-emitting diode technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven current distribution, large effective hole mass, increased production cost and cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

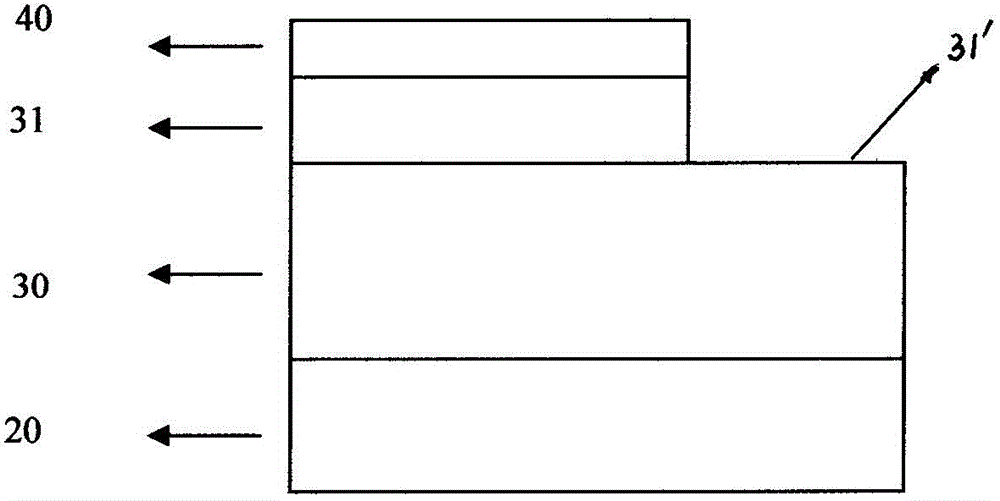

[0034] see Figure 1 to Figure 4 Shown, a kind of graphene film of the present invention is used as the light-emitting diode of carrier injection layer, comprises the following steps:

[0035] 1. On the sapphire substrate 20, epitaxially grow a 0.1 μm thick GaN buffer layer, a 2 μm thick non-doped GaN, a 2 μm thick heavily doped Si n-type GaN electron injection layer 30, and 8 pairs of quantum wells GaN / InGaN to emit light Layer 31 (total thickness 0.15 μm). ;

[0036] 2. Paste the prepared graphene film 40 on the surface of the epitaxial structure, place it in concentrated nitric acid vapor for 1 minute, and then vacuum anneal for 3 minutes;

[0037] 3. Selectively etch the epitaxial structure by photolithography, inductively coupled plasma etching and other processes to expose the N-type GaN electron injection layer to form a mesa 31';

[0038] 4. Prepare the aluminum (Al) / titanium (Ti) / gold (Au) (400 / 50 / 400nm) N-type metal electrode 50 on the table 31' through photolitho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com