LED (Light-Emitting Diode) tube and manufacturing method thereof

A technology for LED fluorescent lamps and LED chips, which is applied to cooling/heating devices, lighting and heating equipment, point light sources, etc. and other problems to achieve the effect of improving system reliability and improving system repair ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

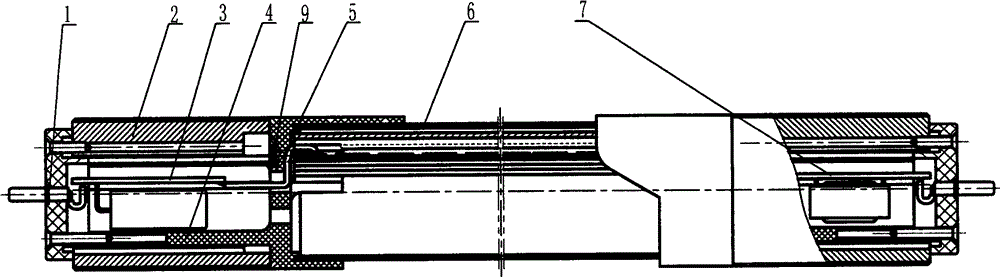

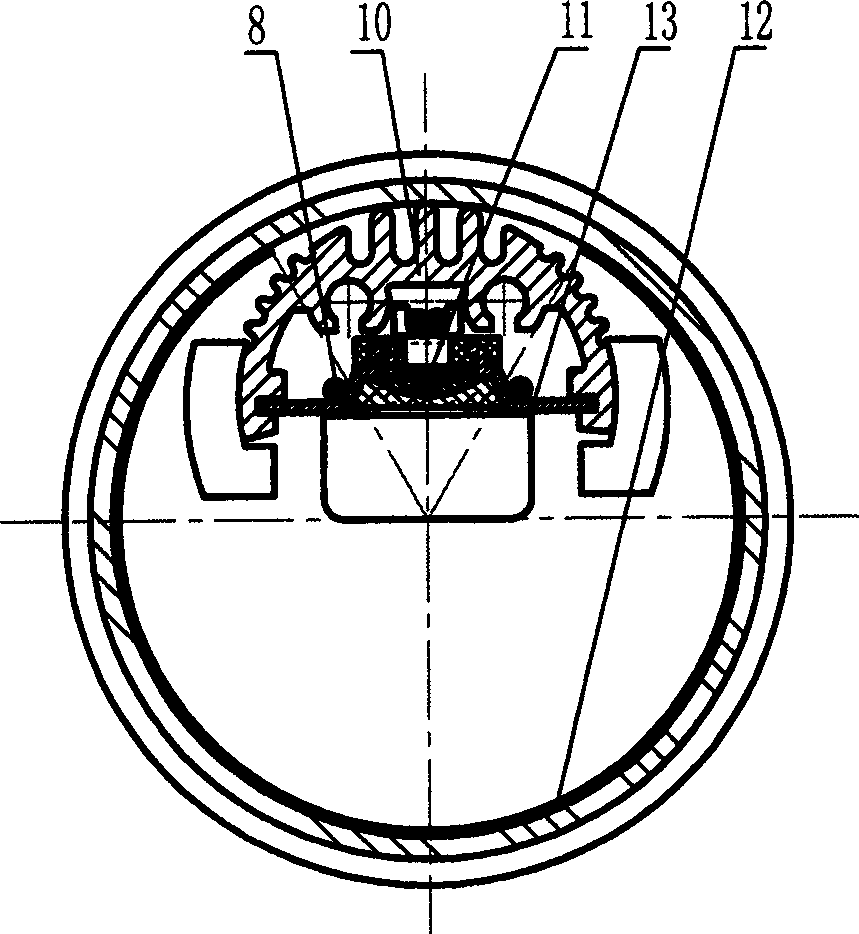

[0031] Embodiment one: if figure 1 , 2 As shown, an LED lamp tube includes: a steel conductive connection for completing the LED fluorescent lamp tube and the lamp holder, and an external copper column connected to the mains to connect the plastic end cover 1; an aluminum shell cover 2; Front power rectification and PFC value compensation module 3; plastic connection sleeve 4; self-adaptive apron pad 5; outer cover transparent glass tube 6; cantilever carrier and plastic connection sleeve 4 of rear drive chip and filter capacitor module 7 and outer cover transparent glass tube 6 axial support components. Front power rectification and PFC value compensation module 3; separate power rectification and PFC value compensation module assembly. The plastic connection sleeve 4 is a support member for the cantilever beam of the parallel circuit bearing panel of the LED chip 11 and the end face of the self-adaptive rubber ring pad 5 . The self-adaptive apron pad 5; self-adaptive to t...

Embodiment 2

[0032] Embodiment two: If the carrier of the mirror surface good heat conductor plate of the LED chip 11 module is housed in embodiment one is preferably a mirror surface aluminum plate, then the rapid absorption of the chip heat and the formation of the external heat transfer volume are greatly reduced. cost. If the cross-section of the diffuser film 12 with light-scattering function formed in an arc shape along the length direction of the inner tube wall of the lamp tube in the first embodiment is infiltrated with a red light-filling transparent pigment, the color rendering of the light of the LED lamp tube can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com