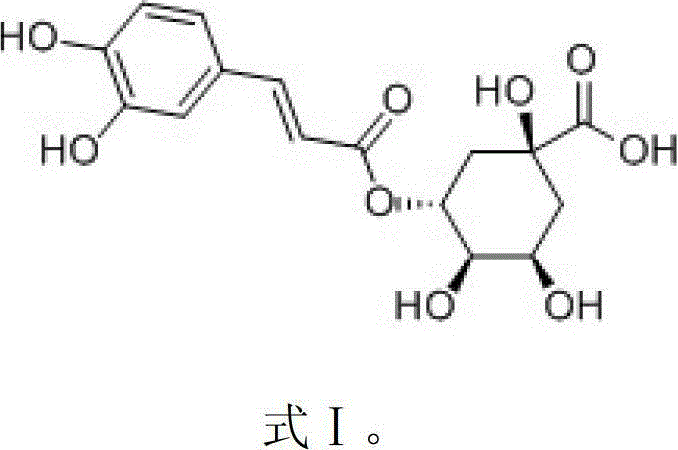

Chlorogenic acid compound and pharmaceutical composition thereof

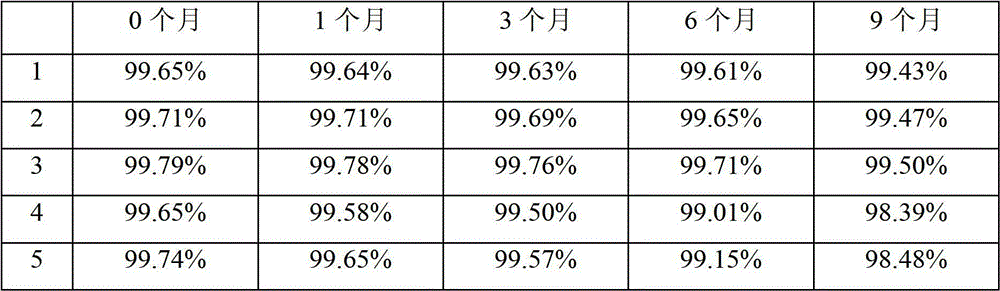

A chlorogenic acid and compound technology, applied in the field of medicine, can solve problems such as poor stability of chlorogenic acid, and achieve the effects of improving drug safety, high bioavailability and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

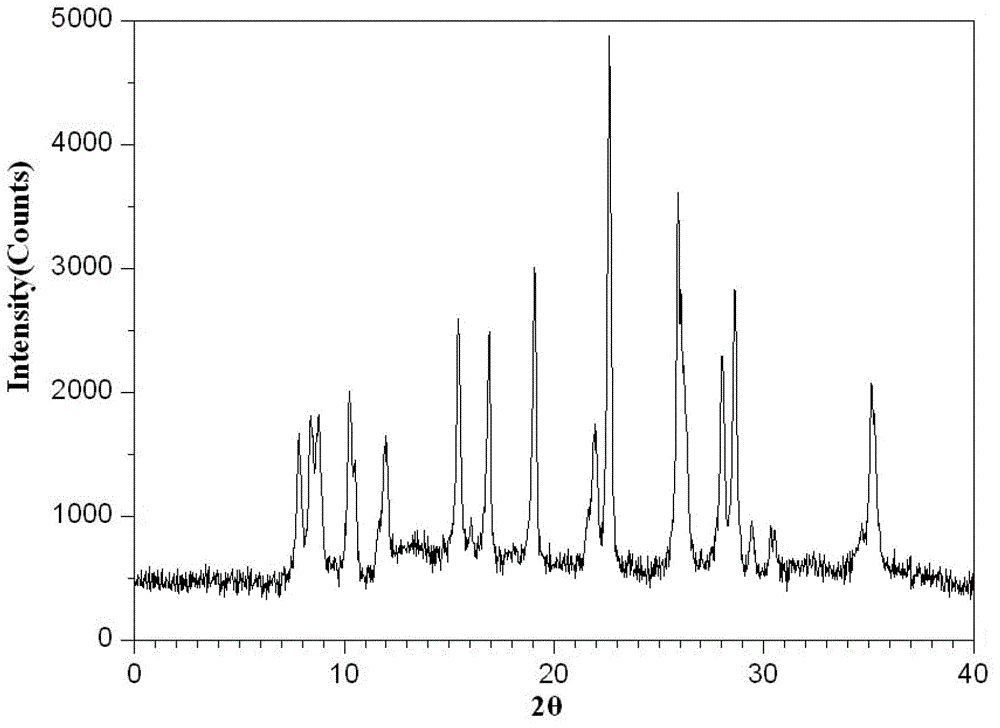

[0043] Preparation of Chlorogenic Acid Compound Crystals

[0044] Dissolve the crude chlorogenic acid in the mixed solution of acetone / isobutanol, wherein acetone and isobutanol are formulated into a mixed solution at a volume ratio of 2:1, and the volume dosage of the mixed solution of acetone / isobutanol is the weight of the crude chlorogenic acid Adjust the pH to 3 with glacial acetic acid, then add activated carbon, stir for adsorption, filter for decarbonization and sterilization, heat to 55°C and stir at constant temperature for 2 hours, then cool down at a rate of 0.7°C / min and under stirring conditions Slowly add ether for crystallization, lower the temperature to 0°C, the stirring rate of adding ether for crystallization is preferably 12rmp, the amount of ether used is 3 times the volume of the acetone / isobutanol mixed solution, filter, dry under reduced pressure, and wash to obtain chlorogenic acid crystals.

[0045] The particle size of the chlorogenic acid crystals...

Embodiment 2

[0048] Preparation of Chlorogenic Acid Compound Crystals

[0049] Dissolve the crude chlorogenic acid in the mixed solution of acetone / isobutanol, wherein acetone and isobutanol are formulated into a mixed solution at a volume ratio of 3:1, and the volume dosage of the mixed solution of acetone / isobutanol is the weight of the crude chlorogenic acid Adjust the pH to 4 with glacial acetic acid, then add activated carbon, stir for adsorption, decarburize and sterilize by filtration, heat to 65°C and stir at constant temperature for 3 hours, then cool down at a rate of 1.2°C / min and under stirring conditions Slowly add diethyl ether for crystallization, lower the temperature to 5°C, the stirring speed of adding diethyl ether for crystallization is preferably 16rmp, the amount of diethyl ether is 4 times the volume of the acetone / isobutanol mixed solution, filter, dry under reduced pressure, and wash to obtain chlorogenic acid crystals.

[0050] The particle size of the chlorogeni...

Embodiment 3

[0053] Preparation of Chlorogenic Acid Compound Crystals

[0054] Dissolve the crude chlorogenic acid in the mixed solution of acetone / isobutanol, wherein acetone and isobutanol are formulated into a mixed solution at a volume ratio of 3:1, and the volume dosage of the mixed solution of acetone / isobutanol is the weight of the crude chlorogenic acid Adjust the pH to 4 with glacial acetic acid, then add activated carbon, stir for adsorption, decarburize and sterilize by filtration, heat to 60°C and stir at constant temperature for 2 hours, then cool down at a rate of 0.9°C / min and keep stirring Slowly add ether for crystallization, lower the temperature to 3°C, the stirring speed of adding ether for crystallization is preferably 15rmp, the amount of ether used is 4 times the volume of the acetone / isobutanol mixed solution, filter, dry under reduced pressure, and wash to obtain chlorogenic acid crystals.

[0055] The particle size of the chlorogenic acid crystals is 75-250 μm, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com