Method for recycling dibasic acid byproducts from adipic acid waste liquor

A technology of dibasic acid and by-products, applied in the field of extracting dibasic acid by-products, can solve problems such as breaking the vacuum, and achieve the effect of increasing residence time and ensuring stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

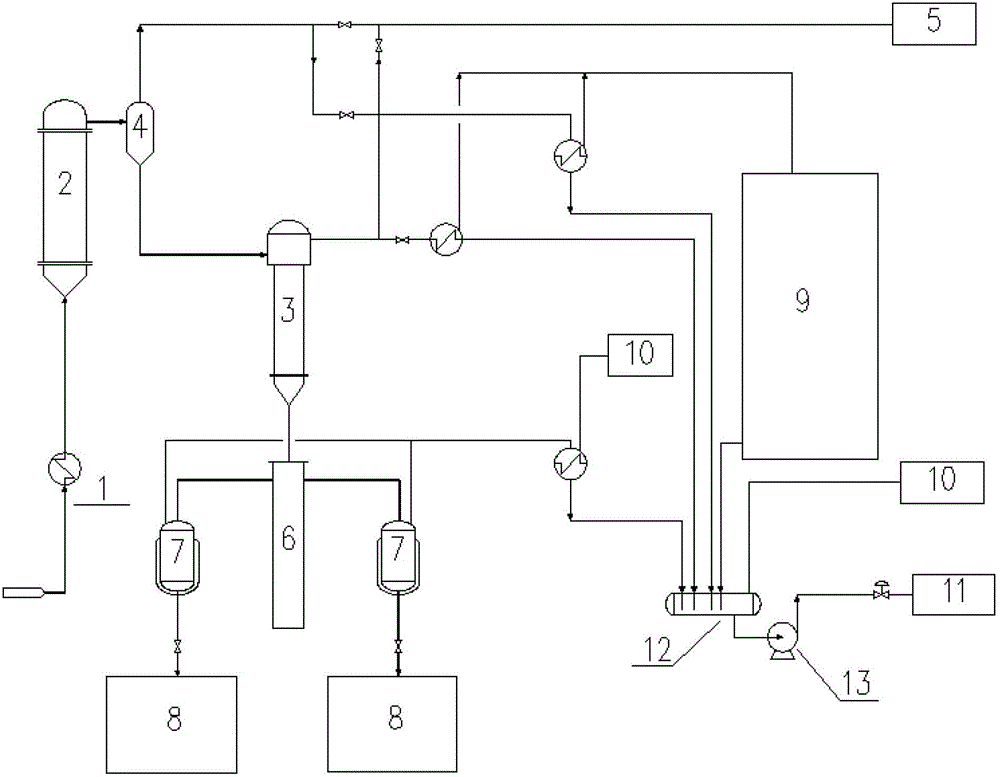

Embodiment 1

[0033] A method for recovering dibasic acid by-products from adipic acid waste liquid. The adipic acid DBA waste liquid is sent to the preheater 1 by conveying and pumping, heated to 75°C with steam condensate, and then enters the rising film evaporator 2 for evaporation and concentration . The outlet temperature of the rising film evaporator 2 is controlled at 90°C and operated at -20~-40kPa A negative pressure. The steam discharged from the top of the rising film evaporator 2 is sent to the nitric acid concentration tower 5 to recover nitric acid together with the steam discharged from the top of the falling film evaporator 3 after the cyclone separator 4 separates the entrained liquid droplets. The moisture content in the output of the rising film evaporator 2 drops to about 40%, and flows to the falling film evaporator 3 for further evaporation and concentration. Falling film evaporator 3 is operated at -70kPaA, heated by medium-pressure steam, and the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com