Separation method of nickel-copper mixed concentrate containing platinum-palladium mineral

A technology of mixing concentrate and separation method, applied in the field of separation, can solve the problems of uneconomical smelting, unstable sorting process, large amount of lime, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

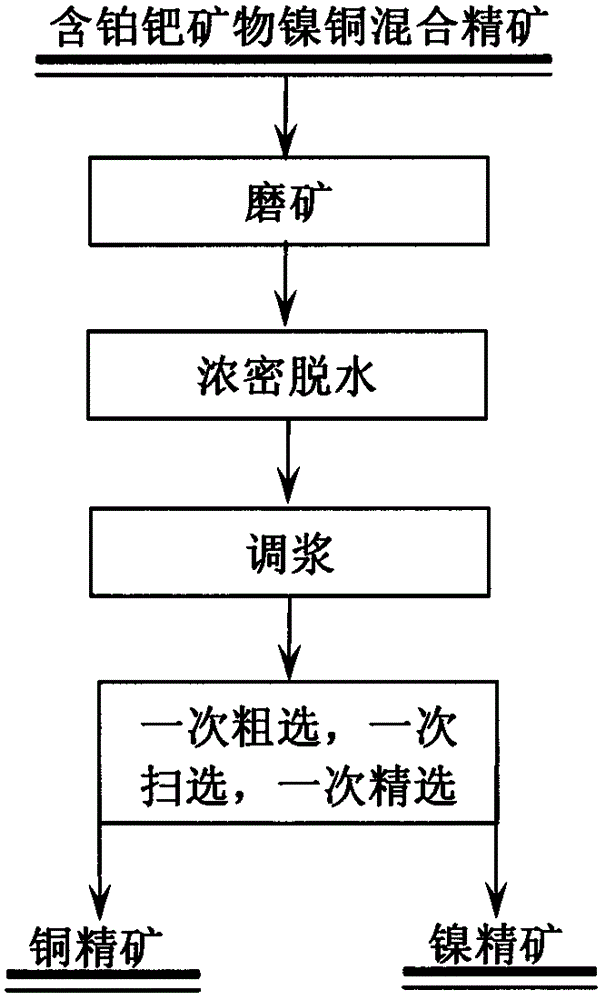

Method used

Image

Examples

Embodiment 1~6

[0016] Table 1 embodiment 1~6 medicament dosage (gram / ton · containing platinum palladium mineral nickel-copper mixed concentrate)

[0017]

Embodiment 1

[0019] Add 800 g / t of activated carbon to the nickel-copper mixed concentrate containing platinum-palladium minerals, grind to -0.043mm, accounting for 85%, and thicken dehydration; add water until the pulp concentration is 35%; add pulp regulator lime to adjust the pH value of the pulp to 12 , operate according to the amount of reagents listed in Table 1 to obtain copper concentrate and nickel concentrate; Palladium 12.51g / t, nickel grade of nickel concentrate is 3.21%, nickel recovery rate is 96.26%, copper content is 1.14%, platinum content is 10.32g / t, platinum recovery rate is 86.18%, palladium content is 23.72g / t, palladium recovery rate 94.45%.

Embodiment 2

[0021] Add 1000 g / t of activated carbon to the nickel-copper mixed concentrate containing platinum-palladium minerals, grind the ore to -0.043mm, account for 90%, and dehydrate it densely; add water to the pulp concentration of 36%; add pulp regulator lime to adjust the pH value of the pulp to 11 , operate according to the amount of reagents listed in Table 1, and obtain copper concentrate and nickel concentrate; Palladium 11.90g / t, nickel grade of nickel concentrate is 3.21%, nickel recovery rate is 96.39%, copper content is 1.07%, platinum content is 10.44g / t, platinum recovery rate is 87.23%, palladium content is 23.79g / t, palladium recovery rate 94.72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com