Copper-cobalt ore beneficiation method

A beneficiation method, copper-cobalt ore technology, applied in the direction of solid separation, etc., can solve the problems of low metal recovery rate, imperfect flotation process, difficulty in floating fine-grained minerals and metal oxide ores, etc., to reduce losses and improve The effect of recovery

Pending Publication Date: 2022-01-07

JINCHUAN GROUP LIMITED

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In view of the imperfect flotation process in the prior art, the fine-grained minerals and metal oxide ores are difficult to float up, resulting in low metal recovery, the present invention provides a method that can effectively reduce the loss of fine-grained metals in tailings and Mineral copper cobalt and gangue minerals are lost in the tailings, and the copper and cobalt ore beneficiation method can significantly improve the recovery rate of copper and cobalt

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

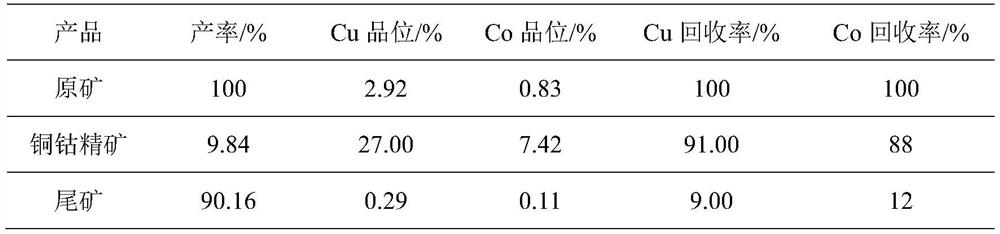

[0041] The ore sample is a copper-cobalt mine in the DRC. The raw ore contains 2.92% copper and 0.83% cobalt.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Login to View More

Abstract

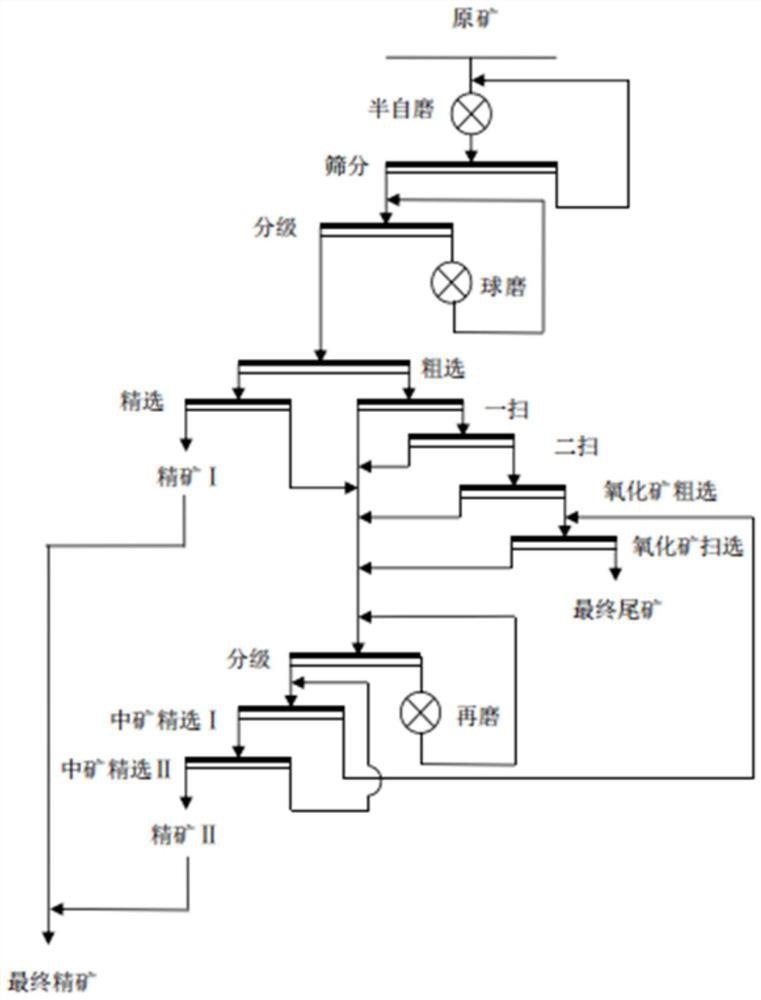

The invention discloses a copper-cobalt ore beneficiation method. According to the copper-cobalt ore beneficiation method, one technological process of semi-autogenous grinding and ball milling is adopted in the crushing and grinding procedure, and one technological process of sulfur first, oxygen second and middling regrinding and reselection is adopted in the grading procedure. Aiming at the facts that useful metals exist in the forms of sulphide ores and oxidized ores at the same time, and the floatability of the sulphide ores is superior to that of the oxidized ores, therefore, flotation of the sulphide ores is performed first, the useful metals in tailings obtained by performing scavenging on the sulphide ores mainly exist in the form of the oxidized ores, at the moment, a vulcanizing agent is added in, the metal oxidized ore which is difficult to float is vulcanized into the metal sulfide ore which is easy to float and then flotation is performed, so that the loss of the metal oxidized ore in the flotation process is reduced, the loss of fine-fraction minerals and useful metal oxidized ores in tailings is effectively reduced, and the recovery rate of copper and cobalt is remarkably increased.

Description

technical field [0001] The invention belongs to the technical field of mineral recovery, and in particular relates to a copper-cobalt ore beneficiation method. Background technique [0002] Copper and cobalt are very important strategic resources and important materials in industrial production. With continuous mining in recent years, there are fewer and fewer easily-selectable copper-cobalt ores with coarse embedded particles, and more and more multi-metallic complex symbiotic refractory copper-cobalt ores with fine embedded particles. Therefore, the recovery of copper and cobalt is becoming more and more difficult when using the conventional beneficiation process in the past, and it is urgent to explore new processes to adapt to changing production conditions. [0003] For the recovery of fine-grained useful metals, due to the large amount of continuous growth with gangue minerals, it is difficult to achieve monomer dissociation during grinding, making it easy for metals ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B03B9/00B03B1/00

CPCB03B9/00B03B1/00

Inventor 赵凯施帅邹晨杰

Owner JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com