Preparation method of novel flotation collector

A collector and flotation technology, used in flotation, solid separation and other directions, can solve the problems of needing heated flotation, poor water solubility at room temperature, large dosage of chemicals, etc., to reduce the cost of beneficiation, less dosage of chemicals, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

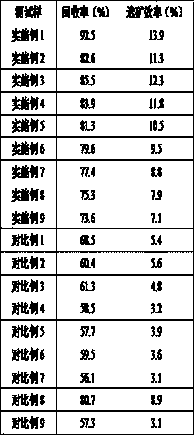

Examples

Embodiment 1

[0010] 1) Weigh 13.7 parts by weight of fusel oil and 22 parts by weight of citric acid and place them in Reactor 1, control the reaction temperature at 40°C, and stir for 2 hours at a constant temperature of 400r / min, then add 5.58 parts by weight of cotton Oil fatty acid soap, continue heating and stirring reaction at this temperature and rotating speed for 2h. After standing for reaction for 12 hours, add 1.56 parts by weight of sodium carbonate (or sodium hydroxide) and 0.68 parts by weight of sodium oleate aqueous solution to adjust the pH = 8.5, place it under the same conditions as above for magnetic stirring for 2 hours, and set aside.

[0011] 2) Add 20 parts by weight of polyethylene glycol and 15 parts by weight of sodium silicate solution with a mass fraction of 10% into the reaction kettle 2, and stir for 1 h at room temperature. Take 60 parts by weight of the solution prepared in step 1) and place it in the reactor 2, heat it in a water bath at 50°C for 30 minute...

Embodiment 2

[0013] It is exactly the same as Example 1, except that 23 parts by weight of citric acid, 5.68 parts by weight of cotton oil fatty acid soap and 3.78 parts by weight of phenoxyacetic acid composite product are added.

Embodiment 3

[0015] It is exactly the same as Example 1, except that 24 parts by weight of citric acid, 5.78 parts by weight of cotton oil fatty acid soap and 3.88 parts by weight of phenoxyacetic acid composite product are added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com