Low-odor type reed pulp black liquor combustion boiler and combustion method thereof

A reed pulp and boiler technology, applied in the combustion method, combustion type, incinerator, etc., can solve problems such as affecting the efficiency of the boiler and continuous operation period, insufficient mixing of air and black liquor, difficulty in adjusting the load of the boiler, etc. The effect of boiler load, disturbance of rising flue gas, and reduction of exhaust heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

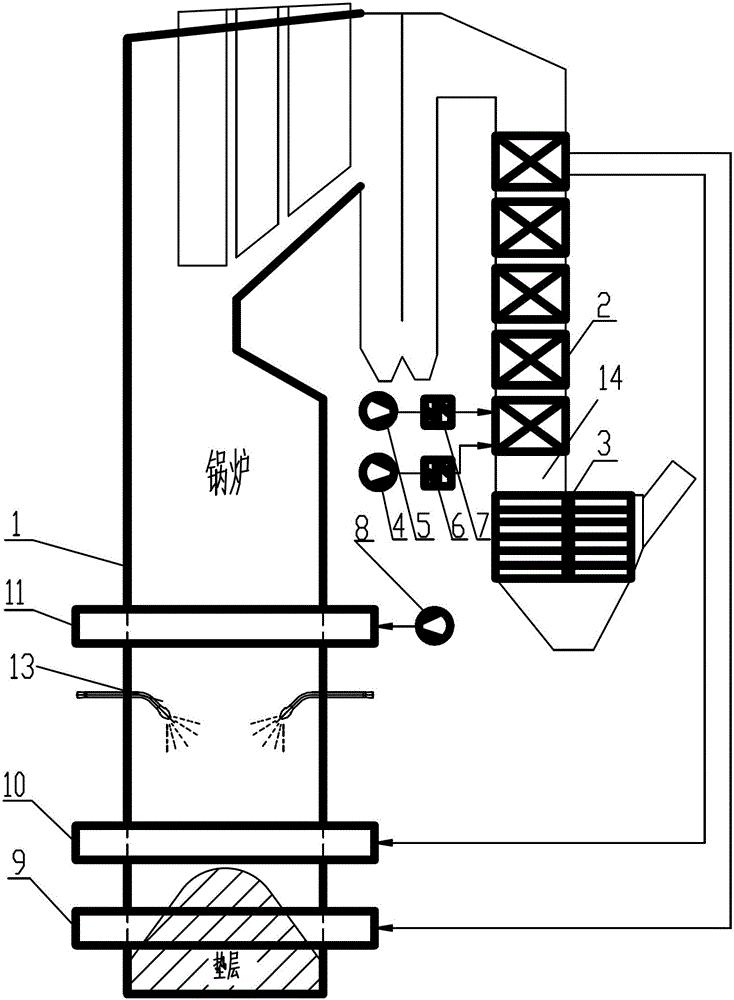

[0030] Boiler furnace body structure of the present invention constitutes the main structure of the combustion boiler, including wall, furnace, heating surface, safety device, smoke exhaust device, reed pulp black liquor spraying combustion device, slag discharge device, etc. It is an existing boiler The main structure, its specific structure is not repeated, and it is described and explained aiming at the technical characteristics of the present invention.

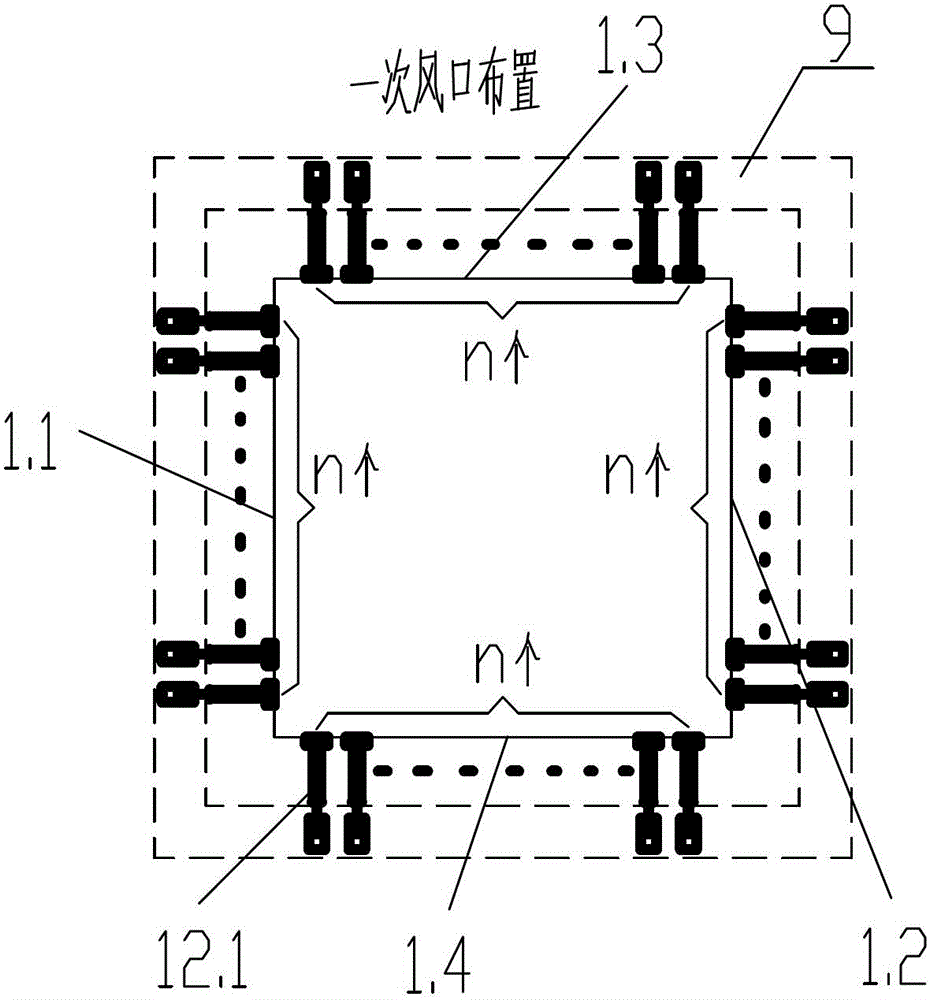

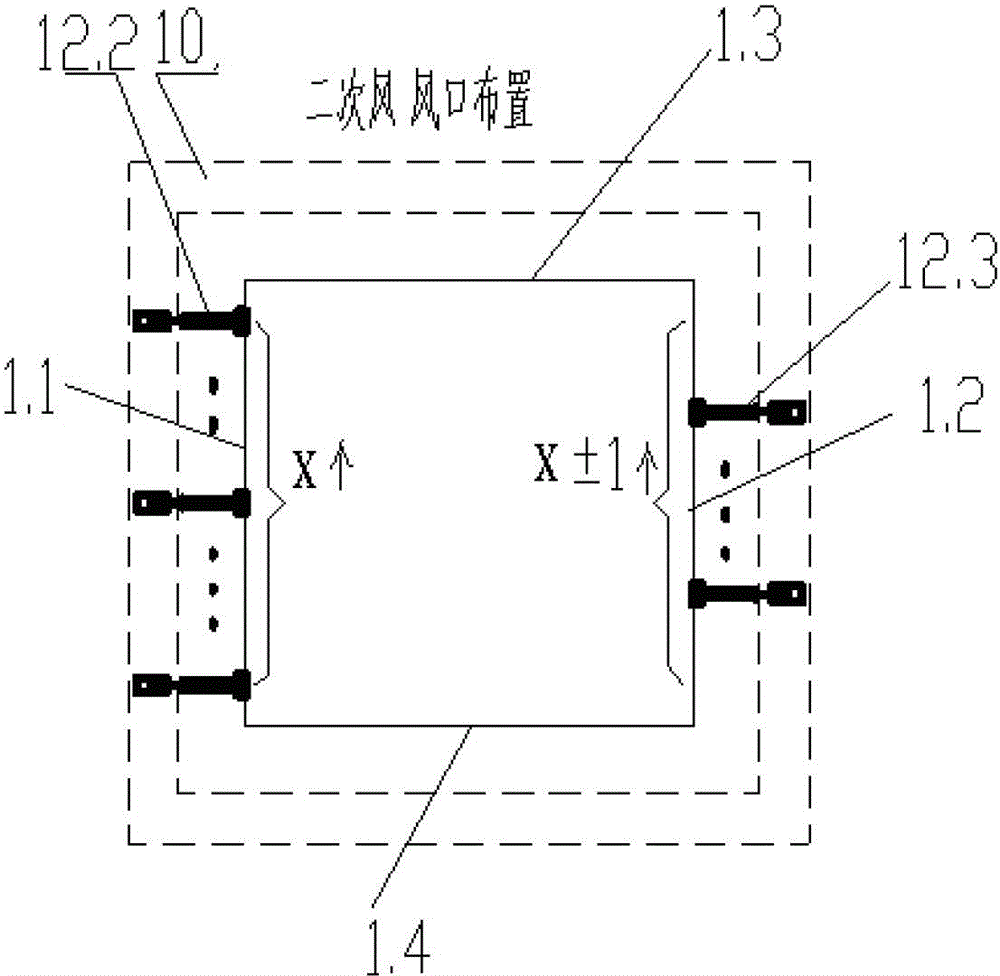

[0031] like figure 1 As shown, the furnace 1 is the main combustion area where air and black liquor are mixed and reacted. The four walls of the furnace are composed of membrane water-cooled walls, and the outside is covered by an insulating layer to reduce heat loss; the furnace 1 in the boiler furnace body structure is equipped with The reed pulp black liquor is sprayed to the combustion device 13. The air supply structure in the furnace 1 includes a primary air supply channel 9, a secondary air supply channel 10 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com